Method for preparing stellate poly quaternary ammonium salt high efficient reverse-phase emulsifier

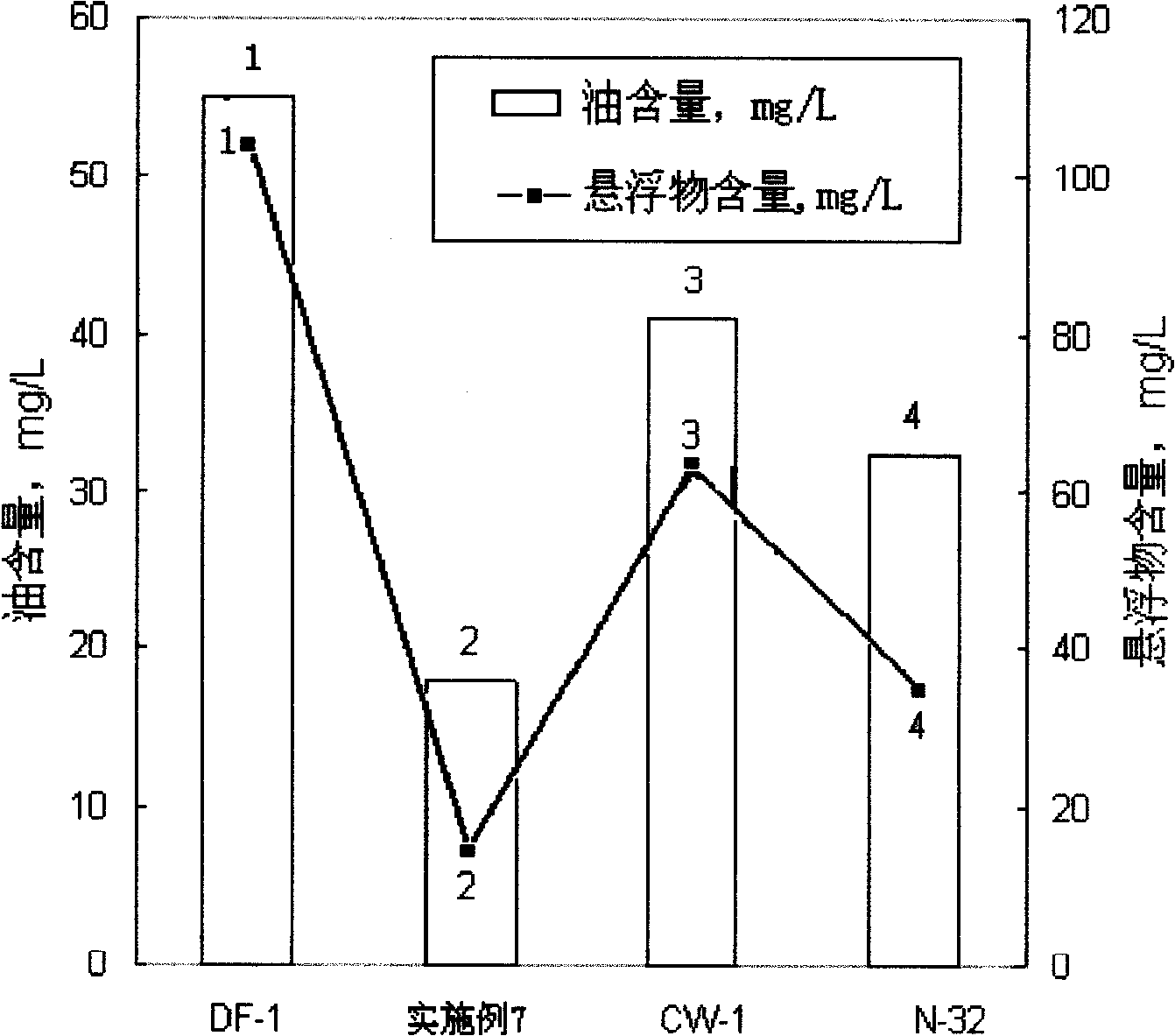

A technology of inverse demulsifier and polyquaternary ammonium salt, which is used in immiscible liquid separation, flocculation/sedimentation water/sewage treatment, etc. It can solve the problem of increased difficulty in oil extraction sewage treatment, unsatisfactory performance, and types of inverse demulsifiers. Single problem, to achieve the effect of simple and easy synthesis process, mild synthesis conditions, and no three waste emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

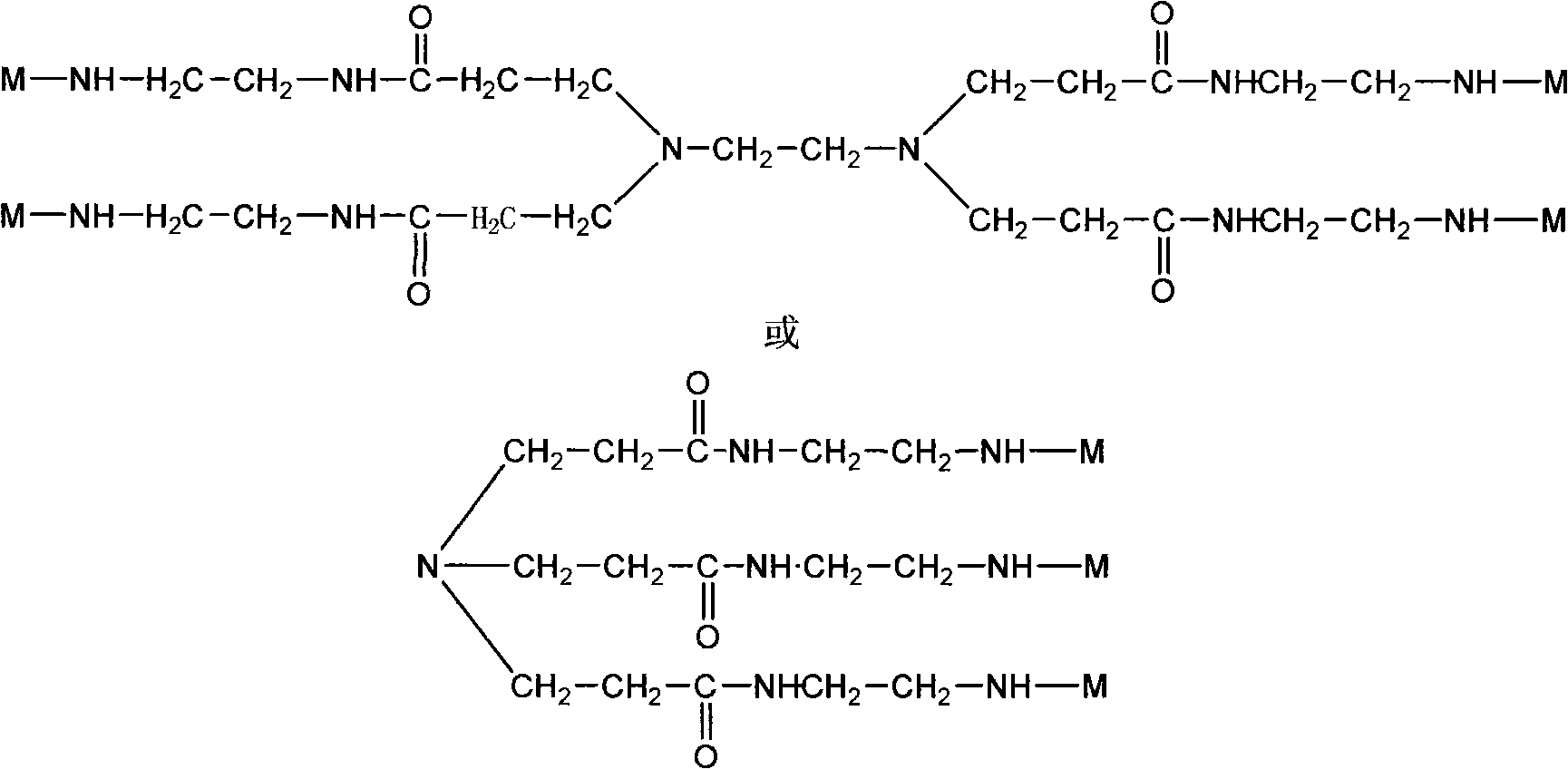

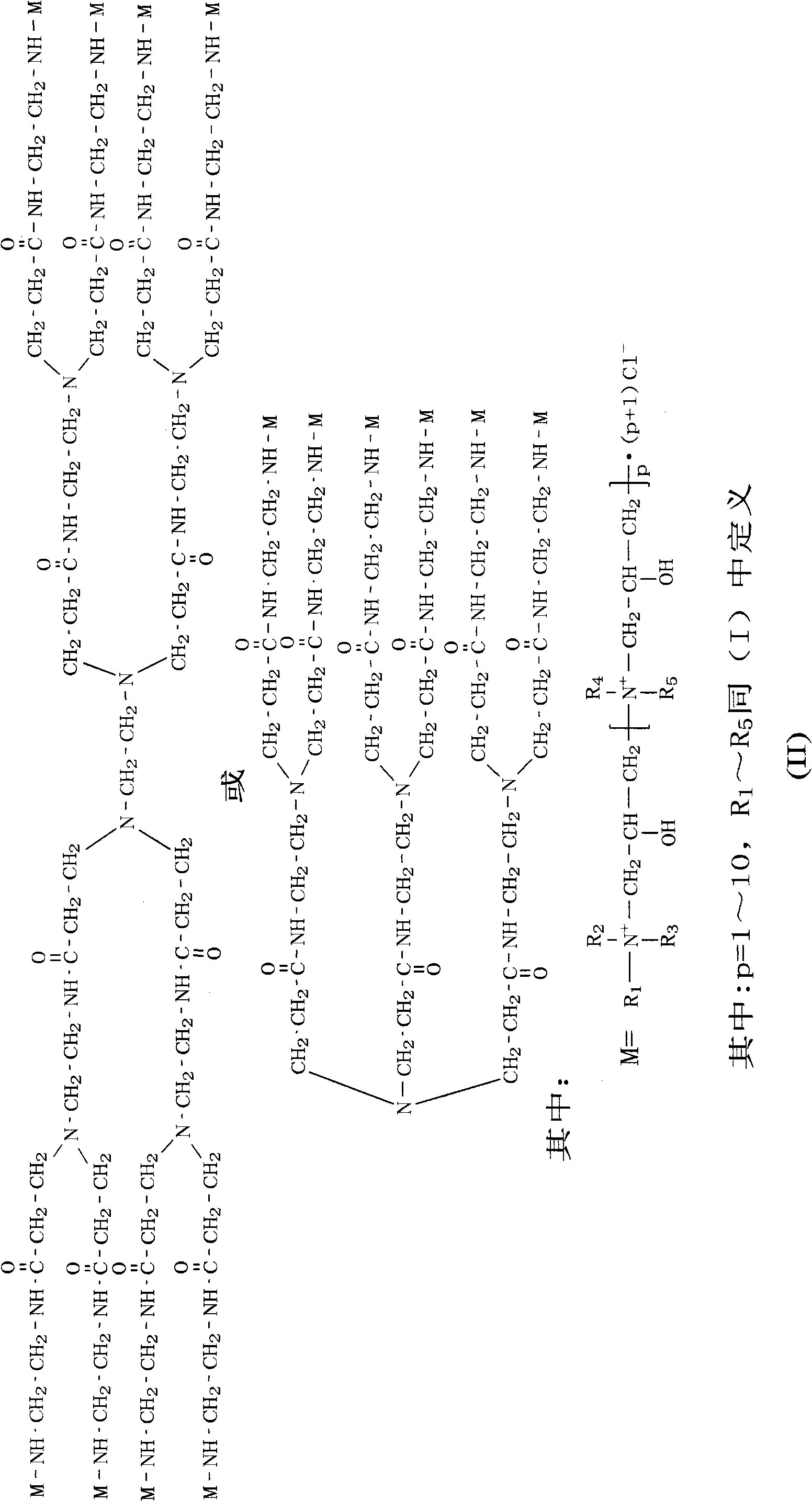

Method used

Image

Examples

Embodiment 1

[0038] Synthesis of 0.5 generation polyamidoamine (PAMAM-0.5G): Add 15.3g (0.25mol) ethylenediamine, 40g ethanol, 0.15gBF to a 250ml four-neck flask 3 ·Et 2 O, add 86.9 (1.0 mol) methyl acrylate dropwise at a constant rate of 1.5 to 2 hours at a temperature of 20-25°C under stirring, and react for 12 hours under stirring at 25°C to obtain a light yellow liquid.

[0039] Synthesis of 1.0th generation polyamide-amine (PAMAM-1.0G): without separation of the 0.5th generation product synthesized above, add 50g of ethanol, stir and control the temperature at 20-25°C, continue to drop 61.2g (1.0mol) ethylene glycol The amine was added in 1.5~2h, and then reacted at 25°C for 12h while stirring. A pale yellow liquid was obtained.

[0040]Synthesis of 1.5 generation polyamide-amine (PAMAM-1.5G): add 63g of PAMAM-1.0G synthesized earlier, 50g of ethanol, 0.10g of BF in a 250ml four-neck flask 3 ·Et 2 O, 43.5 g of methyl acrylate (0.5 mol) was added dropwise, and reacted for 12 h unde...

Embodiment 2

[0043] Synthesis of 0.5 generation polyamido-amine (PAMAM-0.5G): Add 17g (0.25mol) ammonia water (25%), 50g methanol, 0.5gAlCl to a 100ml four-necked flask 3 , 65.2g (0.75mol) of methyl acrylate was added dropwise, and reacted for 8h under stirring at 30°C to obtain a light yellow liquid.

[0044] Synthesis of 1.0 generation polyamide-amine (PAMAM-1.0G): The 0.5 generation product synthesized above is not separated, transferred to a 500ml reaction bottle, added 60g methanol, and continued to drop 45.9g (0.75mol) ethylenediamine, in The reaction was carried out at 35°C for 8h with stirring. A pale yellow liquid was obtained.

[0045] Synthesis of 1.5 generation polyamide-amine (PAMAM-1.5G): add 119g of previously synthesized PAMAM-1.0G, 50g methanol, 0.5g AlCl to a 250ml four-necked flask 3 , 65.2 g of methyl acrylate (0.75 mol) was added dropwise, and reacted for 8 h under stirring at 30° C. to obtain a light yellow liquid.

[0046] Synthesis of 2.0-generation polyamide-ami...

Embodiment 3

[0048] Synthesis of linear polyquaternium (LPQA): add 89.6 g (0.4 mol) of dodecyl tertiary amine in a 2L four-necked reaction flask equipped with a reflux condenser, add 45 g (0.44 mol) of concentrated hydrochloric acid dropwise at room temperature, and then add 100g of methanol, 40.7g of epichlorohydrin (0.44mol) was added dropwise at 40°C, after the addition was completed, the reaction was kept at 55°C for 3h, then 436.5g (3.2mol) of dimethylamine (33%) was added, and 297.6g of dimethylamine (33%) was added dropwise at room temperature Add epichlorohydrin (3.2 mol) for about 1 hour. After the addition, keep the temperature at 40°C for 1 hour, then raise the temperature to 105°C for 1 hour, add 526g of water, and mix well to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com