Aluminum alloy non-welding and roof tile solar heat collector

A solar heat collector and welding-free technology, which is applied in the field of solar heat collectors, can solve the problems that the structure and function of solar heat collectors cannot be properly combined, the speed of popularization of heat collectors is slow, and it is not suitable for large-scale use. Reduce heat transfer distance, improve heat collection efficiency, and reduce material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

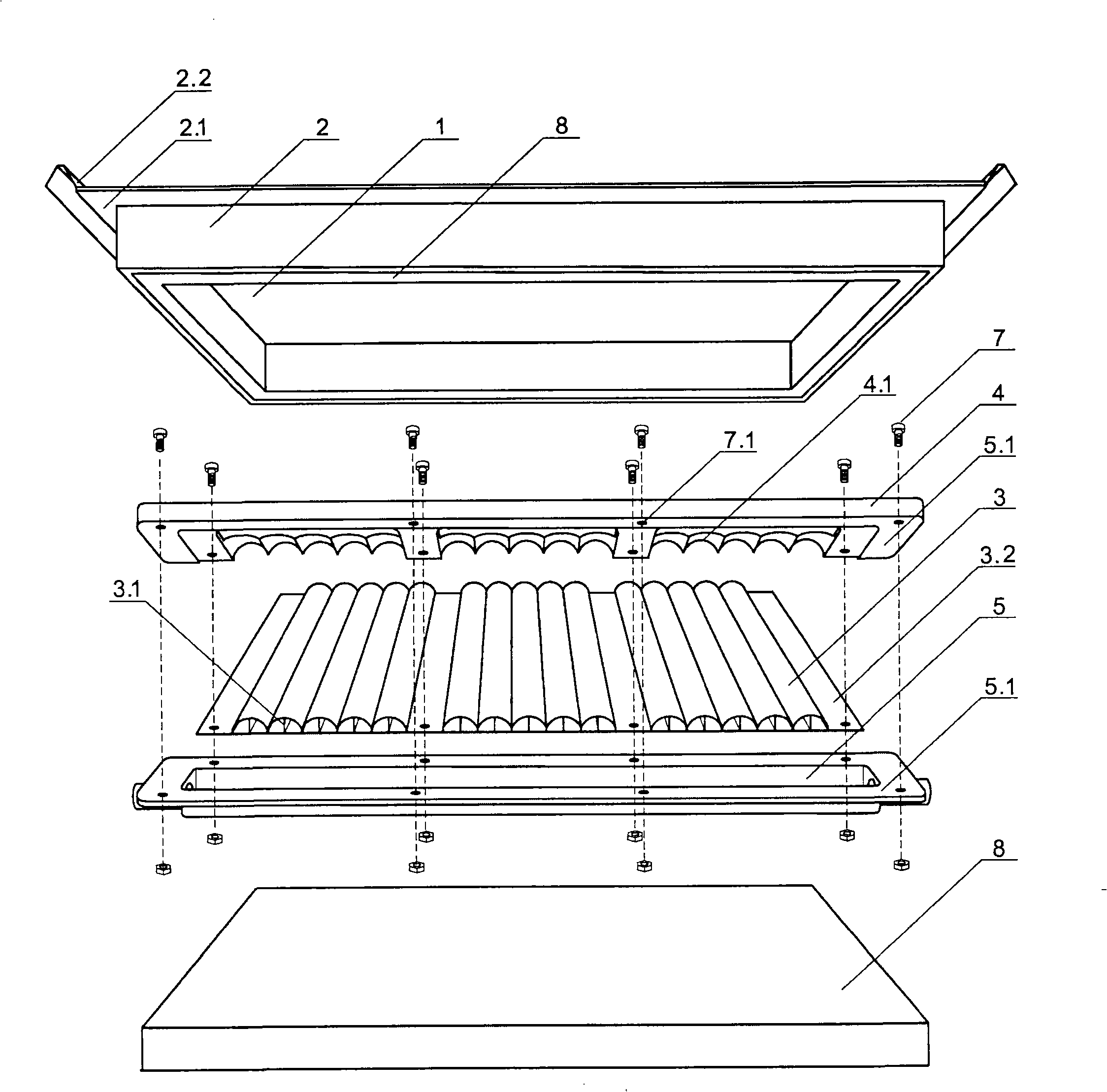

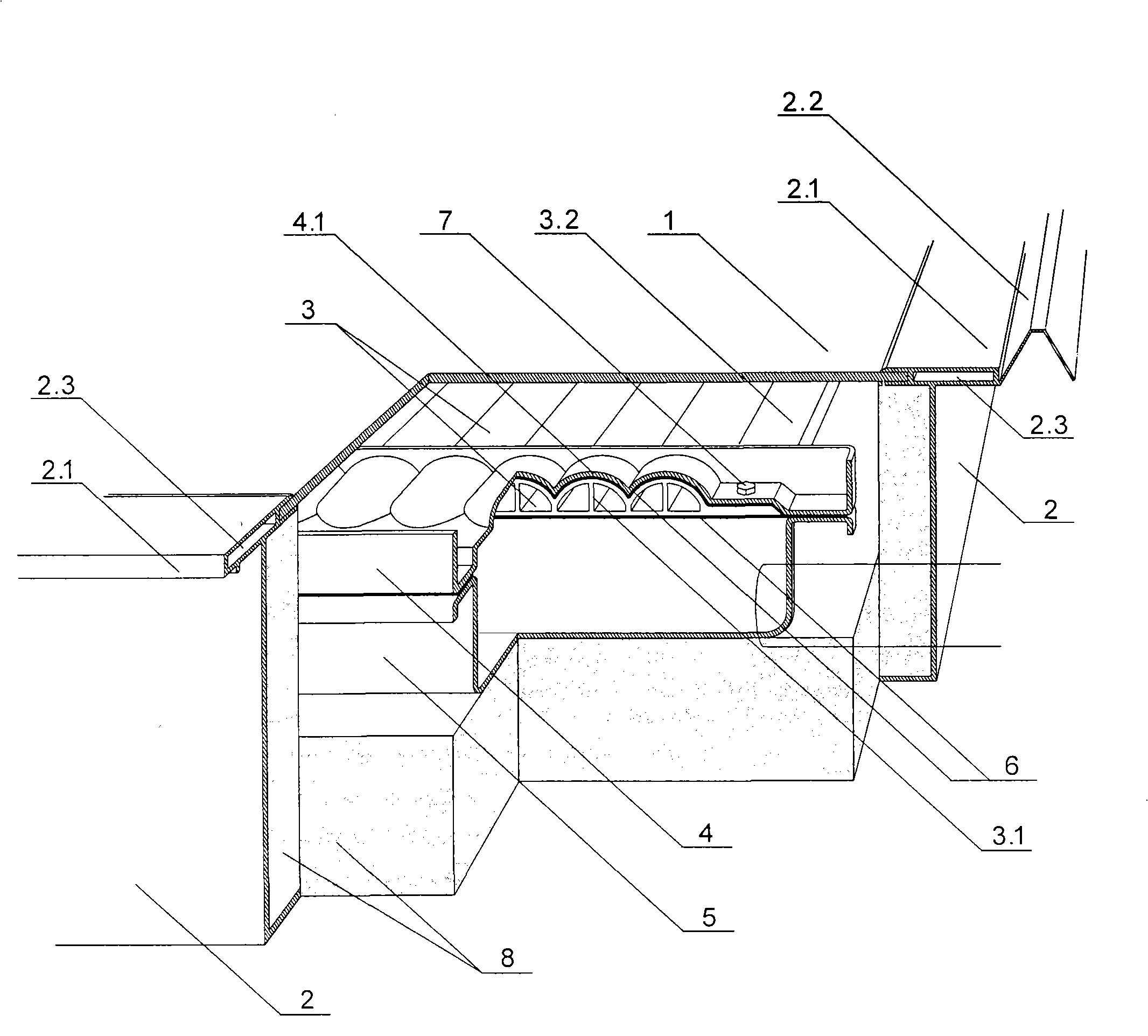

[0043] Examples see figure 1 , 2 As shown, this aluminum alloy solar collector mainly includes a glass cover plate 1, a frame 2, a water pipeline cover plate 4, a heat collecting plate and a heat exchange container 3, and a water pipeline tank 5 arranged and assembled in sequence from the light receiving surface. and insulation layer 8.

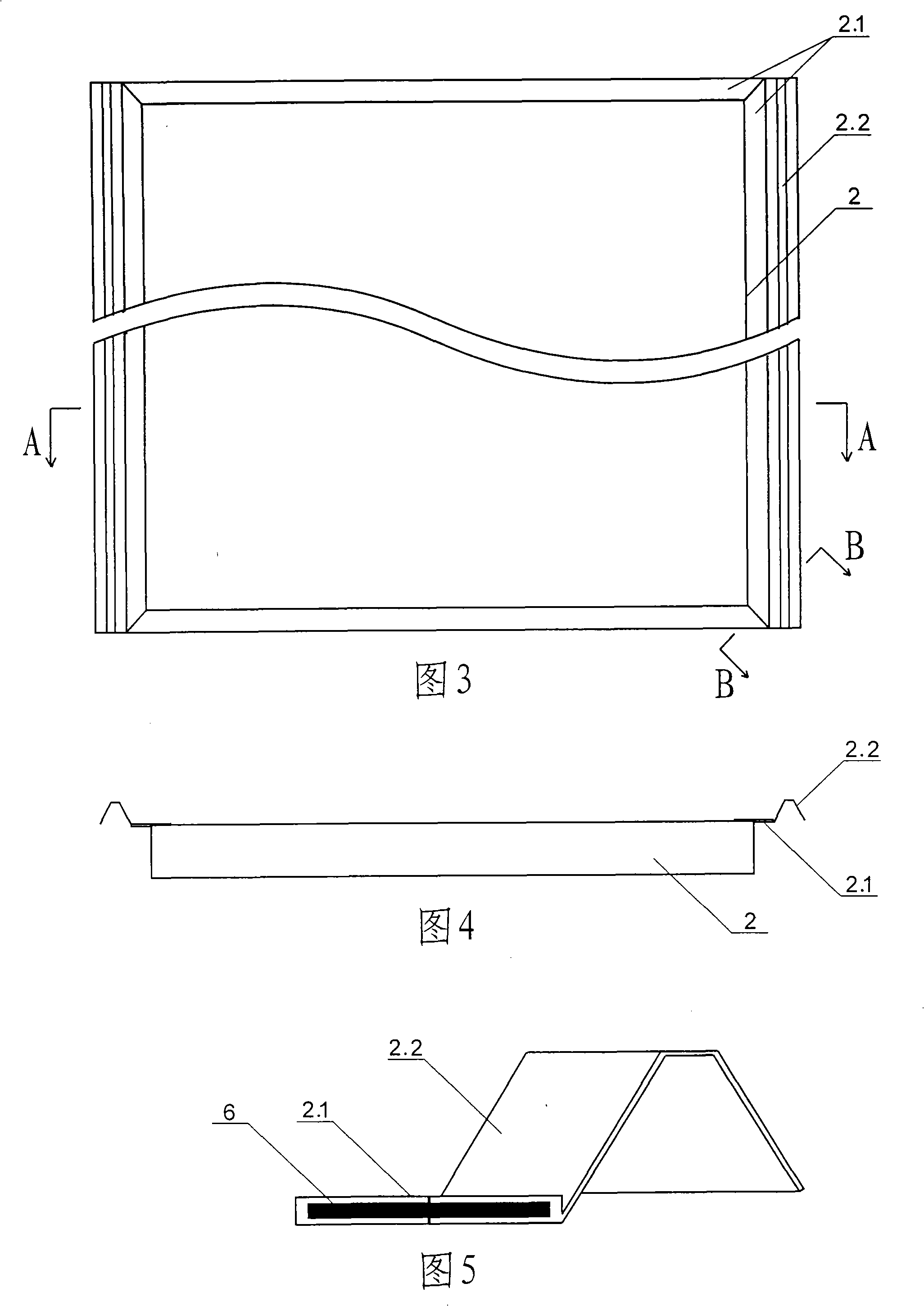

[0044] see Figure 1-6 , the glass cover plate 1 is a heat-resistant light-transmitting glass plate, which is used to allow sunlight to fully pass through and reduce heat loss; it can withstand long-term cold, heat, light, wind, rain, and snow erosion during use, and is subject to hail , stones and other external force collisions will not be damaged. The effect of insulation layer 8 is to reduce heat collector to radiate heat to surrounding environment, require material thermal conductivity to be little, do not absorb water etc., preferably use polyurethane foam product, mineral wool product or expanded polystyrene board. The function of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com