Vanadium-silicon alloy, and preparation and application thereof

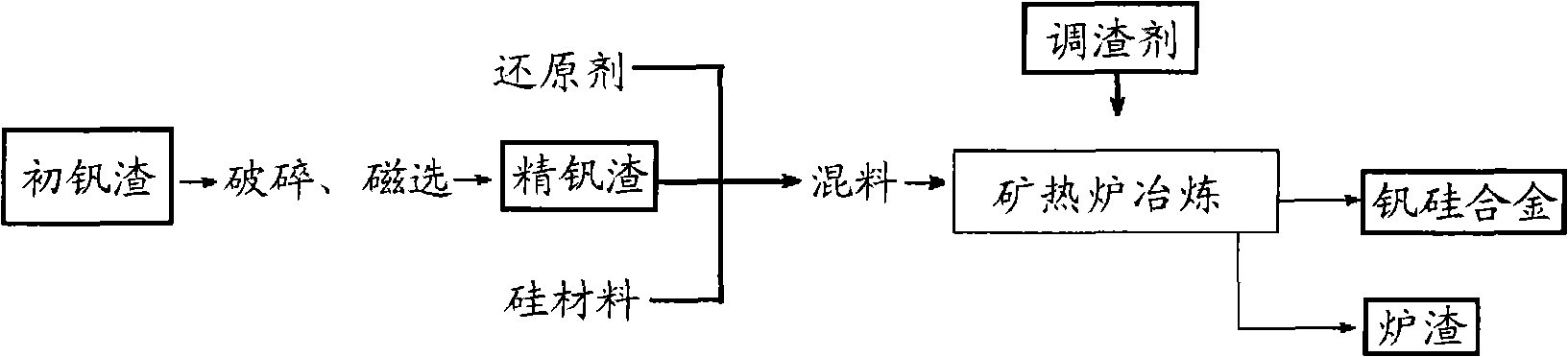

A technology of silicon alloy and vanadium slag, applied in vanadium silicon alloy and its preparation and application fields, can solve problems such as unseen reports, achieve high research value, shorten process flow, and reduce metal loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, the converter containing V 2 o 5 The 14.48% primary vanadium slag is finely ground and magnetically separated to remove iron through a grinding magnetic separator to obtain V-containing slag. 2 o 5 15%, TFe30%, SiO 2 Refined vanadium slag of 14.78%, MnO7.24%, MFe8.7% and other impurities (above are weight percent). Next, mix the refined vanadium slag, coke (with a particle size of 3mm-10mm, fixed carbon (C) content of 84%) and silica with a silicon content of 98% in a mass ratio of 7:7:6. , and the prepared material is sent to the mixer to mix evenly, and then smelted and reduced through a 3200kVA semi-closed submerged thermal electric furnace. While smelting and reducing, a total of 8% lime and 3% Fluorite, so that while ensuring the basicity of the slag, the slag has a certain fluidity, which promotes the reaction and smooth out of the furnace; after the charge is melted, add 0.08% of the total charge to the furnace and the particle size is 3mm-10mm coke, ...

Embodiment 2

[0025] First, the converter containing V 2 o 5 The 15.8% primary vanadium slag is finely ground and magnetically separated to remove iron through a grinding magnetic separator to obtain V-containing slag. 2 o 5 16.2%, TFe29.7%, SiO 2Refined vanadium slag of 14.8%, MnO7.56%, MFe9.1% and other impurities (the above are weight percentages). Next, mix the refined vanadium slag, coke (with a particle size of 3mm-10mm, fixed carbon (C) content of 84%) and silica with a silicon content of 96.63% in a mass ratio of 12:8:5. , and the prepared material is sent to the mixer to mix evenly, and then smelted and reduced through a 3200kVA semi-closed submerged thermal electric furnace. While smelting and reducing, a total of 5% lime and 4% Fluorite: After the furnace charge is melted, add 0.05% of the total charge and coke with a particle size of 3mm-7mm to the furnace, control the reduction time at 170min, and control the end point temperature at 1630°C, and obtain vanadium-silicon allo...

Embodiment 3

[0028] First of all, after extracting vanadium in the converter to obtain V-containing 2 o 5 The primary vanadium slag of 19.42% is crushed and magnetically separated by a grinding magnetic separator to obtain V-containing slag. 2 o 5 20%, TFe22%, MnO6.58% and other impurity refined vanadium slag. Next, mix the refined vanadium slag with the above-mentioned composition and content, pulverized coal coke (with a particle size of 1mm-3mm, fixed C content of 82%) and mountain sand with a silicon content of 92% in a mass ratio of 2:1:1 , send the prepared material into the mixer to mix evenly, and then pass through a 3200kVA semi-closed submerged thermal electric furnace for smelting and reduction. While smelting and reducing, add 10% lime and 5% fluorite as auxiliary materials. Material: After the charge is melted, add 0.1% of the total amount of coal powder with a particle size of 1mm-3mm to the furnace, control the reduction time at 150min, and release the furnace at the end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com