Method and apparatus for preparing Li-B alloy by vacuum smelting

A technology of vacuum smelting and vacuum smelting furnace, which is applied in the field of metallurgy, can solve the problems of alloy electrode performance degradation, ineffective absorption, single temperature control, etc., and achieve the effect of preventing alloy performance degradation, compact and reasonable design structure, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention provides a method and device for preparing Li-B alloy by vacuum smelting. The present invention will be further described below with reference to the accompanying drawings and embodiments.

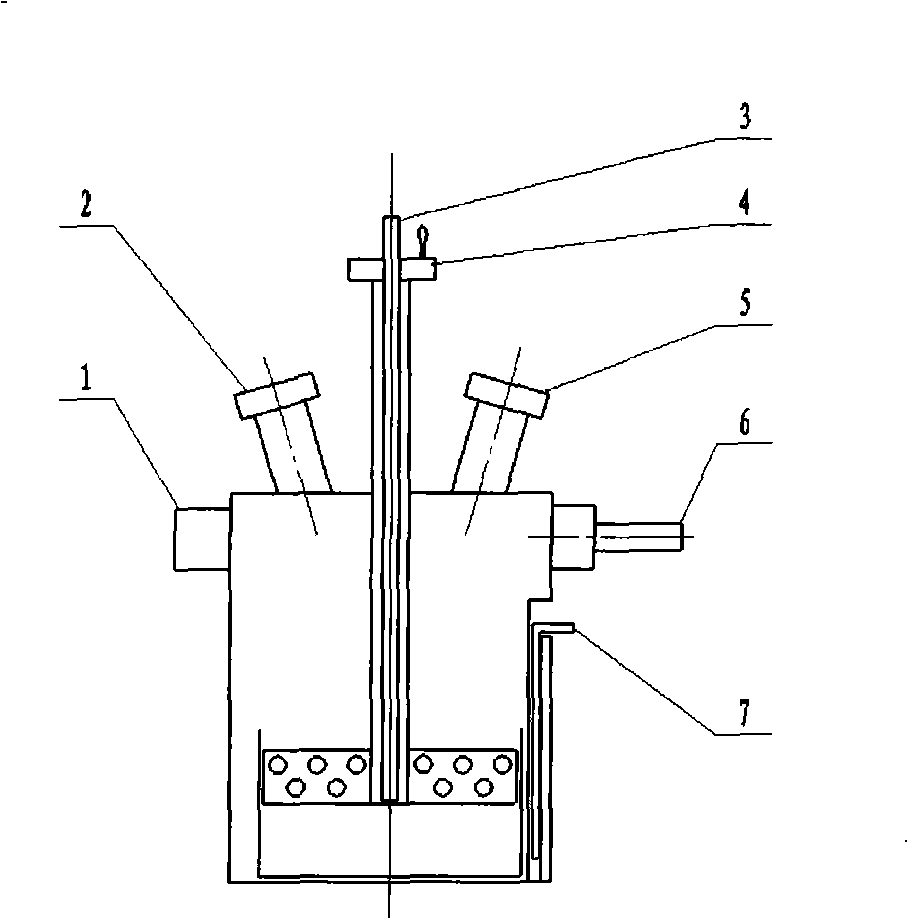

[0021] On the one hand, the present invention provides an apparatus for preparing Li-B alloy by vacuum melting, figure 1 Shown is a schematic diagram of the structure of the vacuum melting furnace device. The device is a vacuum smelting furnace. A temperature-controlled armored thermocouple 7 is set on the outside of the crucible; a stirring paddle 4 is set at the center of the smelting furnace. The unfolded length of the stirring paddle blade is less than the diameter of the crucible, and some uniform blades are set Distributed round holes with appropriate pore size, the size of the pore size is suitable for the melt to pass through the round holes and achieve the purpose of stirring; set the temperature measurement armored thermocouple 3 at the bottom of the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com