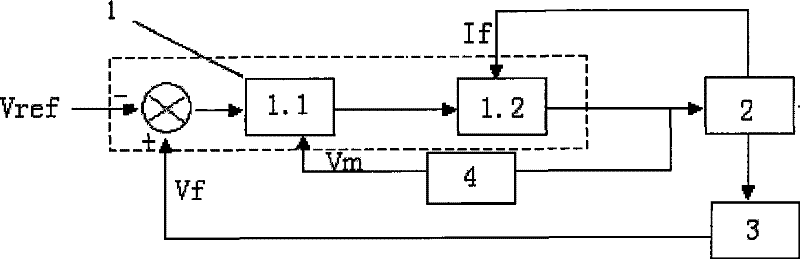

Control method of buried arc welding arc voltage feed back wire feeding and circuit

A control method and control circuit technology, applied in arc welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as complexity, low control precision, interference, etc., and achieve the effect of simple control, improved control precision, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

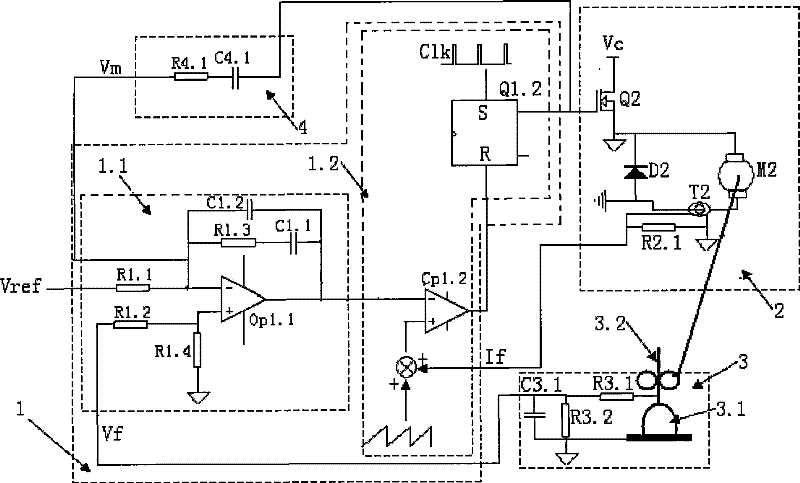

[0025] Example 2: In figure 2When the integral capacitor C1.1 is short-circuited, the regulator 1.1 becomes a proportional regulator, which is characterized by fast response. R1.3=1000kΩ, R1.4=1000kΩ, R4.1=100kΩ, C4.1=1.5uF. The remaining parameters are the same as the previous example. The advantage of the proportional regulator is that the response speed is relatively fast.

[0026] image 3 It is the external wiring diagram of UC3846. UC3846 is a current-mode PWM control chip, which integrates the functions of the inner loop controller 1.2 and is easy to use. Please refer to the instruction manual provided by the manufacturer for the chip schematic diagram, symbol description and usage method. The slope compensation of the feedback current If can be realized by connecting the resistance network composed of R1.5, R1.6 and R1.7 outside the chip. When using this chip, the figure 2 Medium controller 1.2 canceled, figure 2 The output terminal of Op1.1 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com