[0007] (3) High-temperature composting method: Composting has relatively few nutrients, and additional

nitrogen or

phosphorus or

potassium fertilizers must be added to meet the national standards for commercial fertilizers. The content of inorganic substances and heavy

metal ions is high, and the percentage of water-soluble nutrients is low. Plants Difficult to absorb, low

fertilizer efficiency,

low resource utilization rate, high

processing cost

[0008] In order to overcome the

weakness of the above method, some technical solutions for solving this problem have been disclosed, for example: Chambers discloses the equipment for producing hydrocarbons from

waste tires and industrial and

domestic waste in USP 4.235.676, the disclosed The equipment adopts a vacuum

system and the reaction kettle is fixed. This method is easy to

coke, difficult to remove

slag, and the production cannot be continuous.

In the applicant's USP 5,744,668, USP 6,133,491 and CN 1068032C, it is disclosed that

domestic waste is subjected to thermal

cracking and catalytic cracking at two different temperatures twice, using

continuous feeding and continuous slagging methods and equipment; There are many kinds of organic substances in the food. To completely decompose high-molecular-weight organic substances (poultry viscera,

skin, hair, and bones), they must be treated at a high temperature of 800-1000°C to make them completely decomposed and harmless. Therefore, The technical equipment disclosed and described in the above-mentioned patents cannot meet the high-temperature conditions required for harmless garbage, so there are defects; today, the high-temperature-resistant steel commonly used in the market or industry, that is, stainless steel or

titanium alloy steel, is also difficult to maintain for a long time. It can withstand high temperature conditions above 800°C and is expensive; therefore, in the actual process of industrialized

domestic waste treatment, the use temperature of the cracking equipment material is generally 400-600°C; the

temperature resistance of the cracking equipment material limits the cracking equipment. It is difficult for the

pyrolysis temperature of garbage to reach 850-1000°C; that is to say, the

pyrolysis that occurs at a temperature of 400-600°C cannot make certain organic substances (such as

animal organs, skins, fur, bones) It is completely decomposed, and the residue after cracking still contains quite a lot of undecomposed organic substances, which must be further processed to make it completely decomposed or harmless, so as to meet the requirements of

environmental protection or harmlessness; however, the steel rotary Type reactor is prone to cylinder deformation and cannot rotate normally when it is in high temperature environment for a long time; similarly, the

stress change of the second-stage spiral reactor under high temperature is prone to deformation of cylinder material and shaft bending, so that the spiral reactor cannot Long-term operation at high temperature causes the heavy organic matter (such as animal bones,

skin or internal organs) in the garbage to be completely decomposed and harmless because the temperature does not meet the required high temperature requirements.

[0009] In CN1242856C, a fixed horizontal reactor cracking domestic waste equipment is disclosed. The

agitator in the equipment is prone to

material deformation and shaft bending when subjected to stress changes at high temperatures, and cannot rotate, resulting in some waste in the waste.

Organic matter (such as

animal skin or viscera) cannot be completely decomposed because the temperature does not meet the required high temperature requirements, and domestic waste cannot be completely harmless; fixed reactors are prone to

material deformation due to uneven heating for a long time, Poor

heat transfer,

high energy consumption, and intermittent feeding. There is a

weakness of low

waste disposal capacity per unit time. It cannot meet the requirements of large-scale

processing of increasing piles of domestic waste. There are defects in industrial practicability.

[0010] To sum up, none of the single various cracking methods, single various

incineration methods or various types of intermittent

waste disposal methods can meet the requirements of neither producing dioxin C 2 h 4 o 2 , and can make domestic waste completely harmless and achieve large-scale

continuous treatment of domestic waste and other requirements

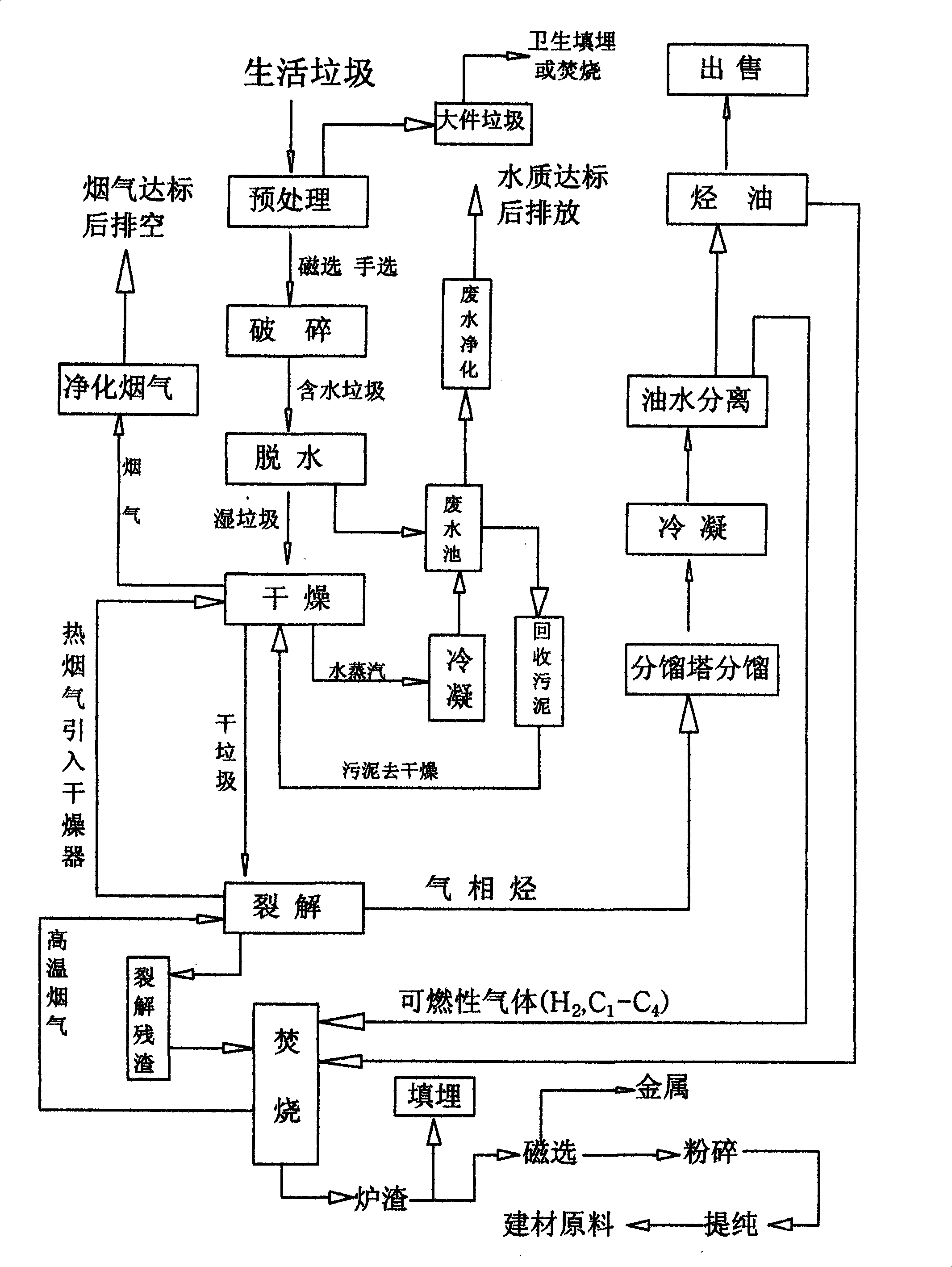

[0011] The purpose of the present invention is to overcome the technical defects of the above-mentioned various single cracking methods, various single incineration methods or various intermittent treatment of domestic waste, and provide a method that can meet the requirements of not producing dioxins simultaneously 2 h 4 o 2 , which can realize the large-scale, continuous, resourceful (the energy in the garbage is stored in the form of

hydrocarbon oil), reduction, energy saving,

environmental protection, high efficiency and other requirements of domestic

waste treatment Login to View More

Login to View More  Login to View More

Login to View More