Soldering method and semiconductor module manufacturing method

A welding method and technology of manufacturing method, applied in semiconductor/solid-state device manufacturing, semiconductor device, welding equipment and other directions, can solve the problems of increasing welding man-hours and complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

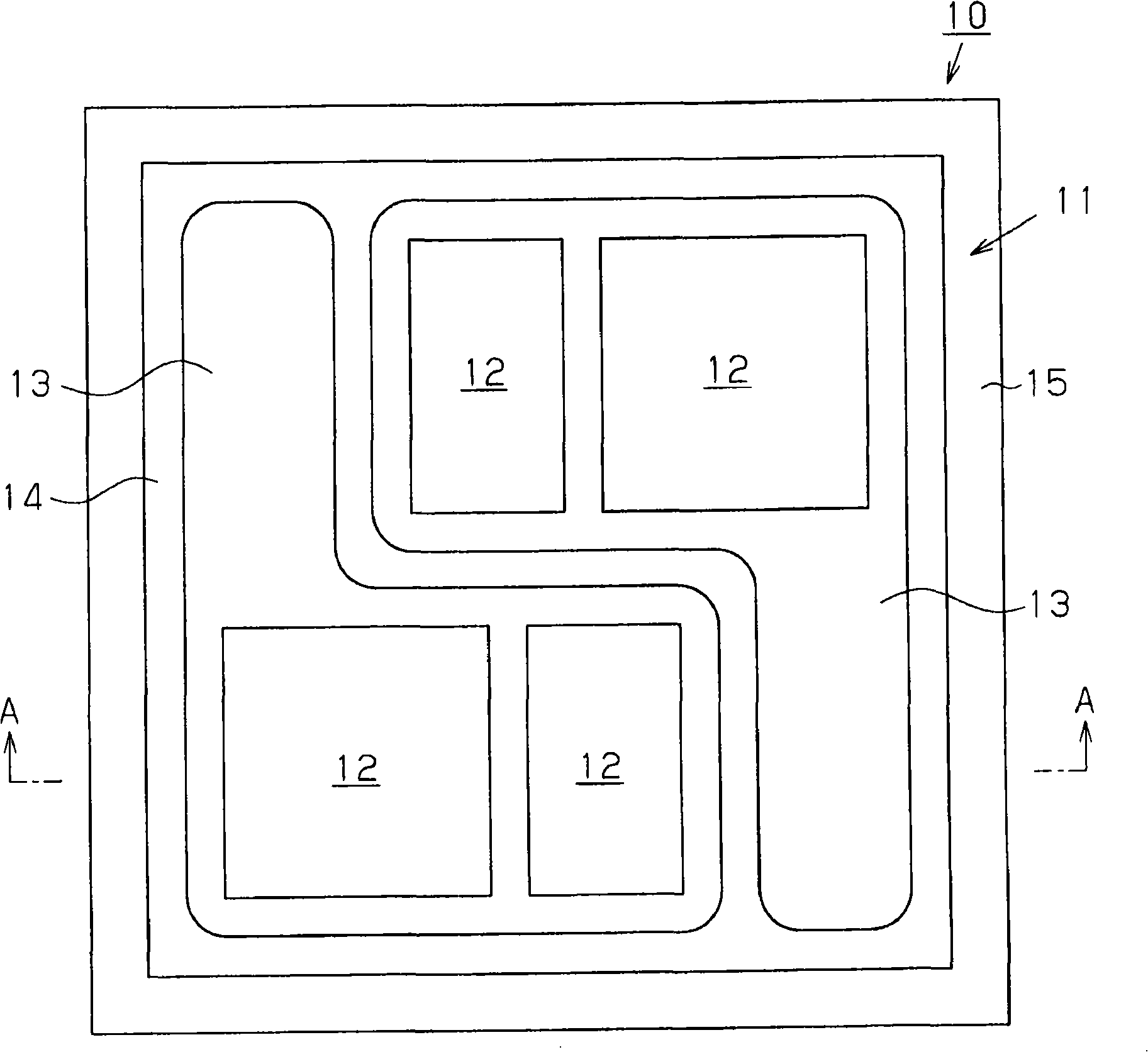

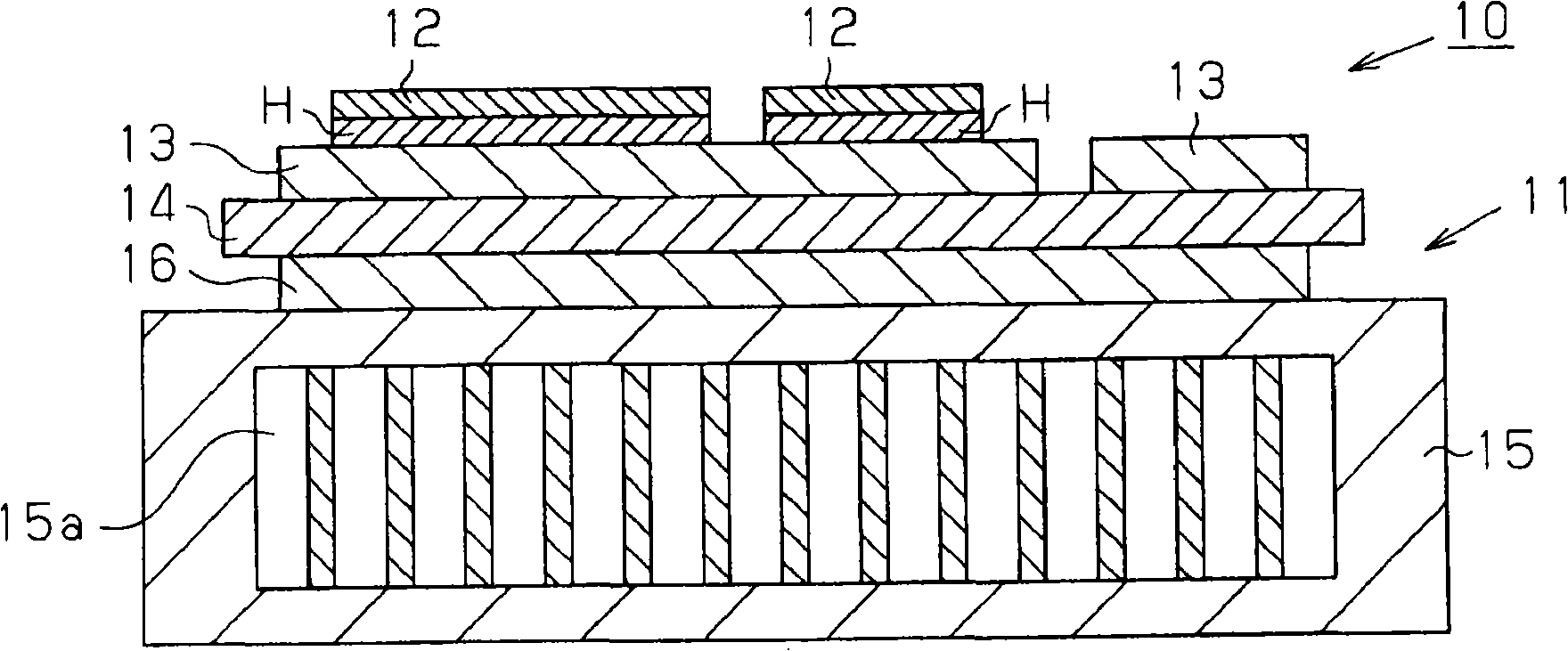

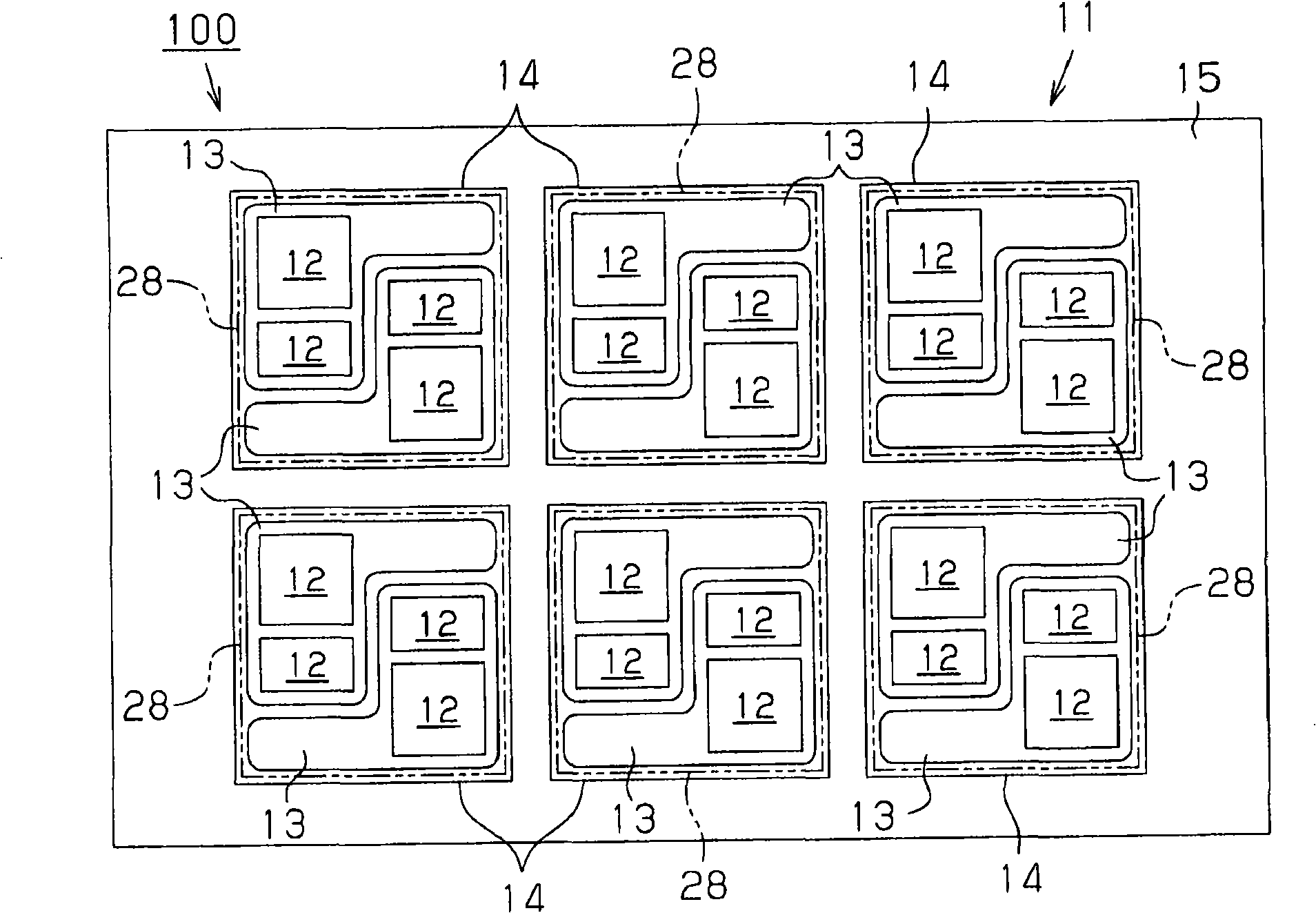

[0024] Below, according to figure 1 ˜ FIG. 5 describe a first embodiment that actualizes the present invention.

[0025] The semiconductor module 10 includes: a circuit board 11 ; and at least three semiconductor elements 12 that are not aligned on a straight line on the circuit board 11 . figure 1 and figure 2 The illustrated semiconductor module 10 includes four semiconductor elements 12 . The circuit board 11 includes: a ceramic substrate 14 as a ceramic insulator having a metal circuit 13 on its surface; and a metal heat sink 15 fixed to the ceramic substrate 14 via a metal plate 16 . That is, the circuit board 11 is a cooling circuit board, that is, a board with a heat sink. The radiator 15 is formed of aluminum-based metal, copper, or the like, and includes a refrigerant flow path 15 a through which a cooling medium flows. The aluminum-based metal refers to aluminum or an aluminum alloy. Metal plate 16 functions as a bonding layer for bonding ceramic substrate 14 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com