Electrolytic solution for improving lithium manganate lithium ion battery performance

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as capacity decay, electrolyte decomposition acceleration, explosion, etc., to slow down capacity decay, suppress co-insertion, and enhance circulation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In addition to ethylene carbonate, ethyl methyl carbonate, diethyl carbonate, propylene carbonate, and lithium hexafluorophosphate, the electrolytic solution for improving the performance of lithium manganate lithium ion battery provided by this embodiment also contains a film-forming additive. The additives may be, but not limited to, consist of 1,3-propane sultone, lithium bisoxalate borate.

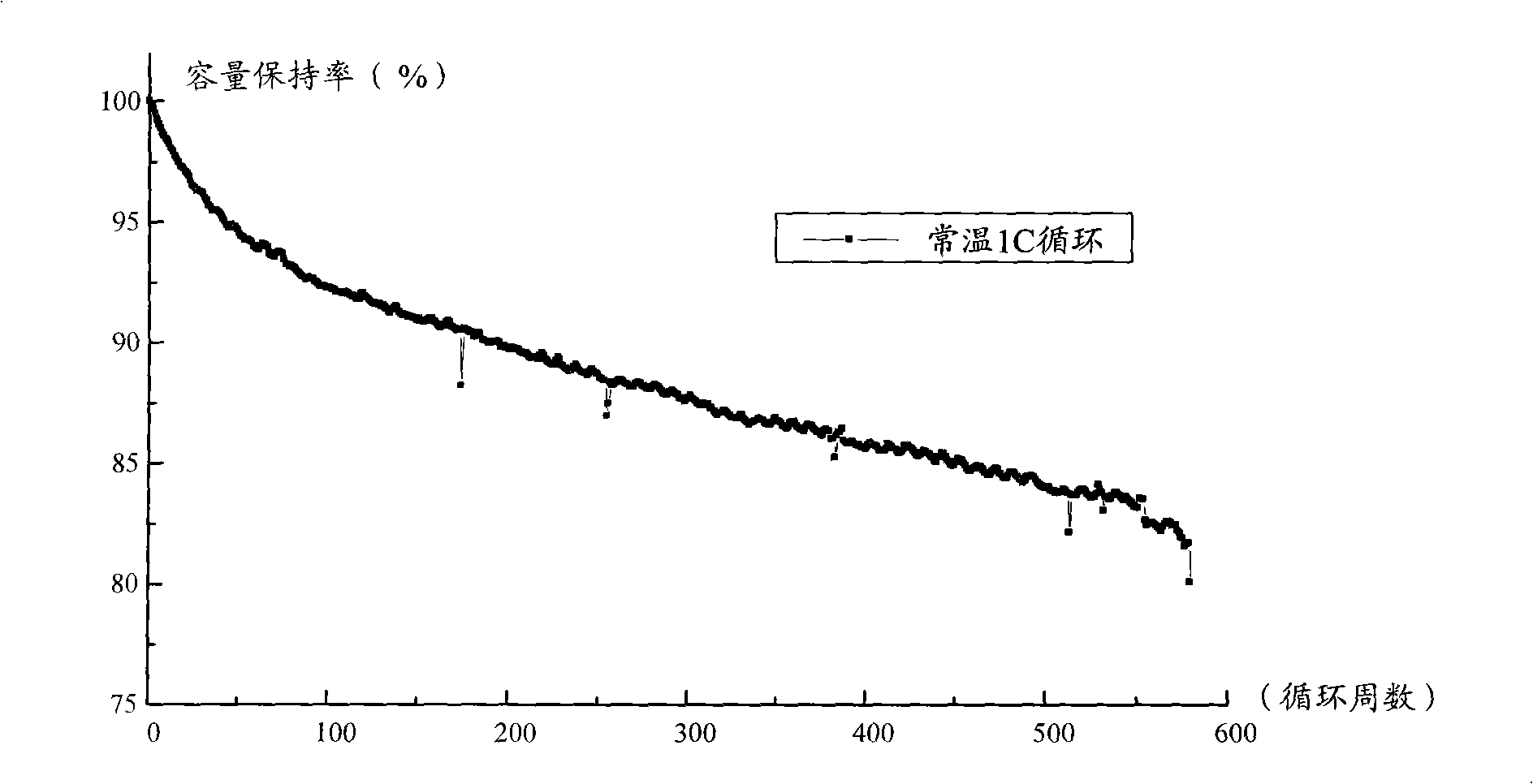

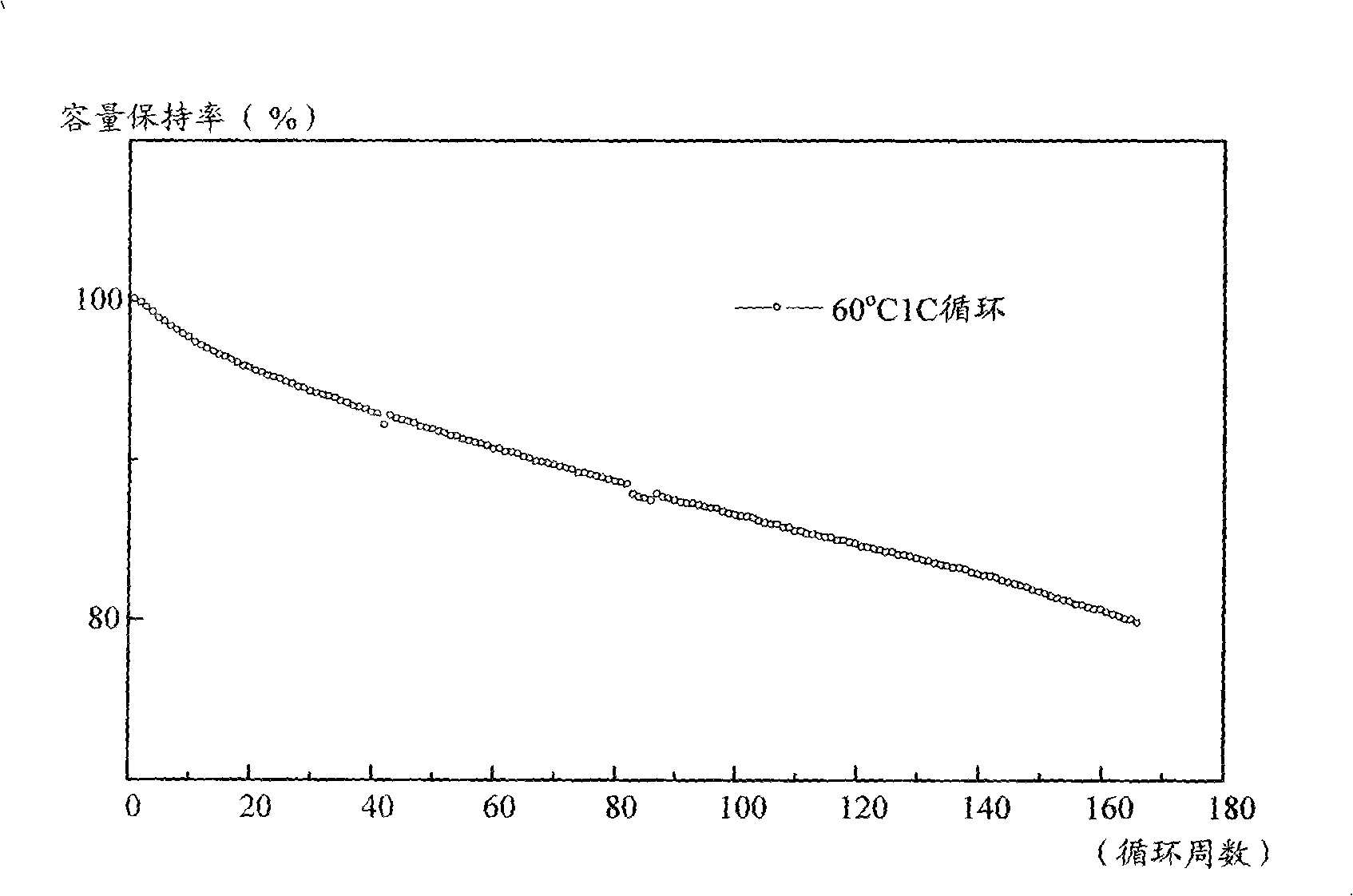

[0031] Since the film-forming additive is included in the electrolyte of the lithium manganate lithium-ion battery, when the battery is formed, the film-forming additive forms a stable high-temperature-resistant passivation film (SEI film) on the electrode surface, which can effectively inhibit the positive electrode (main material) of the battery. Lithium manganese oxide) reacts with the electrolyte to reduce the dissolution of manganese ions, ensure that the battery has good high-temperature storage performance, and slow down the capacity decay of the battery during cycling.

...

Embodiment 2

[0036] As a preferred embodiment, the lithium manganate lithium ion battery electrolyte of this embodiment includes: ethylene carbonate, ethyl methyl carbonate, diethyl carbonate, propylene carbonate, lithium hexafluorophosphate, 1,3-propane sultone , Lithium oxalate borate. Wherein the proportioning of each component is as follows:

[0037] The weight ratio content of ethylene carbonate is 20-30%, the weight ratio content of ethyl methyl carbonate is 20-30%, the weight ratio content of diethyl carbonate is 20-30%, and the weight ratio content of propylene carbonate is 20%. ~30%, 1,3-propane sultone ratio content is 5~15%, lithium hexafluorophosphate concentration is 0.5~0.9mol / L, lithium bisoxalate borate concentration is 0.1~0.5mol / L.

[0038] Due to the addition of additives in this embodiment, the film-forming action of the film-forming additive has suppressed the effect with the negative electrode of graphite, so the content of propylene carbonate can be appropriately in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com