Lithium ion battery cathode and preparation method thereof

A lithium ion battery and negative electrode technology, applied in the field of lithium ion battery negative electrode and its preparation, can solve problems such as decrease in charge and discharge capacity, battery failure, loss of electrical contact, etc., and achieve the effects of good cycle performance and large reversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Mix and stir 0.85g carbon-coated silicon with 0.05g conductive carbon black, 10g styrene-butadiene rubber-carboxymethylcellulose sodium emulsion (solid content 1wt%) for 6 hours, and then apply to 20 micron thick porous poly On the surface of the vinyl film, vacuum-dry at 40°C for 8 hours to obtain a carbon-coated silicon layer;

[0036] (2) Mix and stir 0.9g acetylene black and 10g styrene-butadiene rubber-sodium carboxymethyl cellulose emulsion (solid content 1wt%) for 4 hours, then apply it to the surface of the carbon-coated silicon layer, and dry it in vacuum at 50°C for 10 hours , to obtain a lithium ion battery negative electrode.

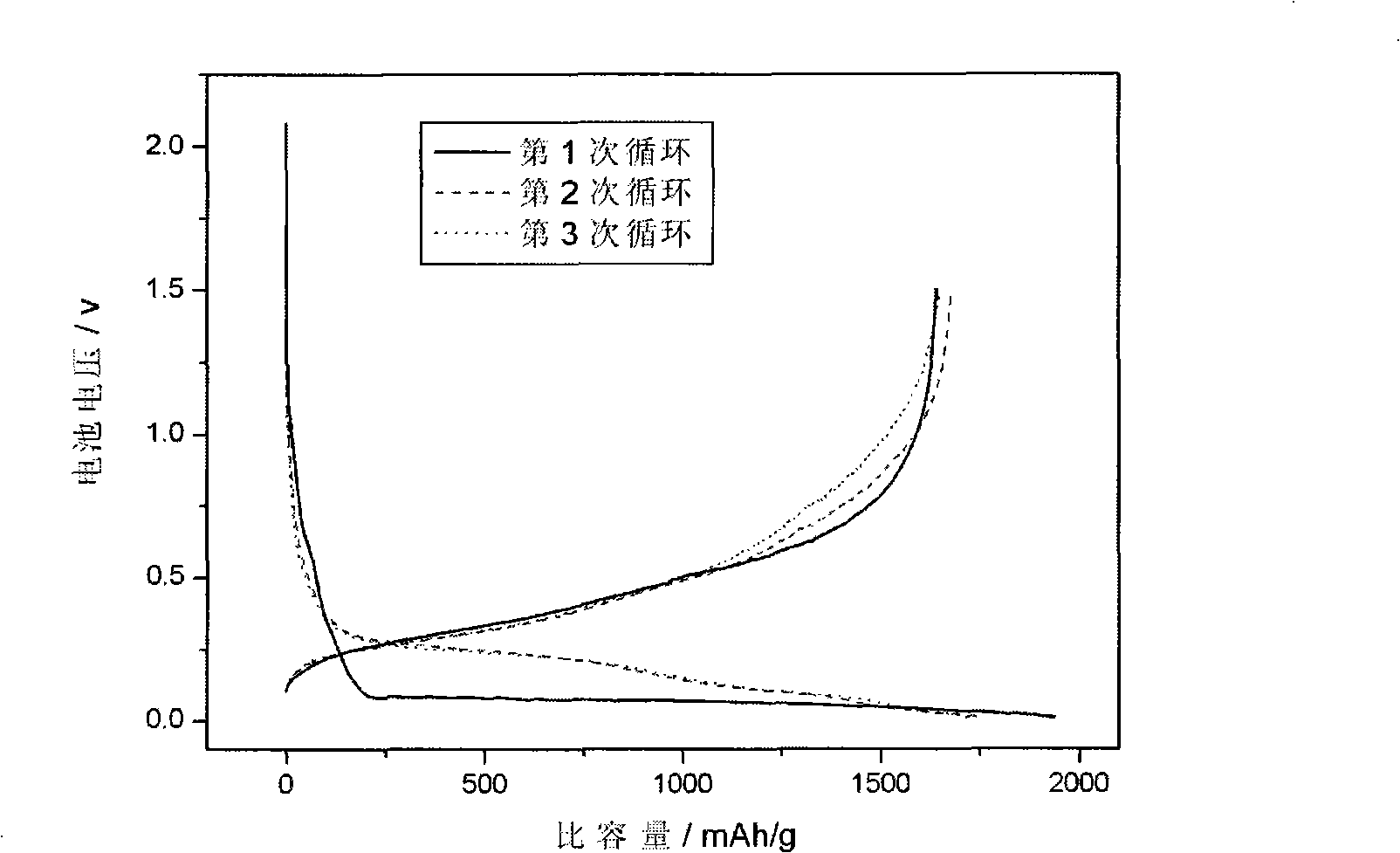

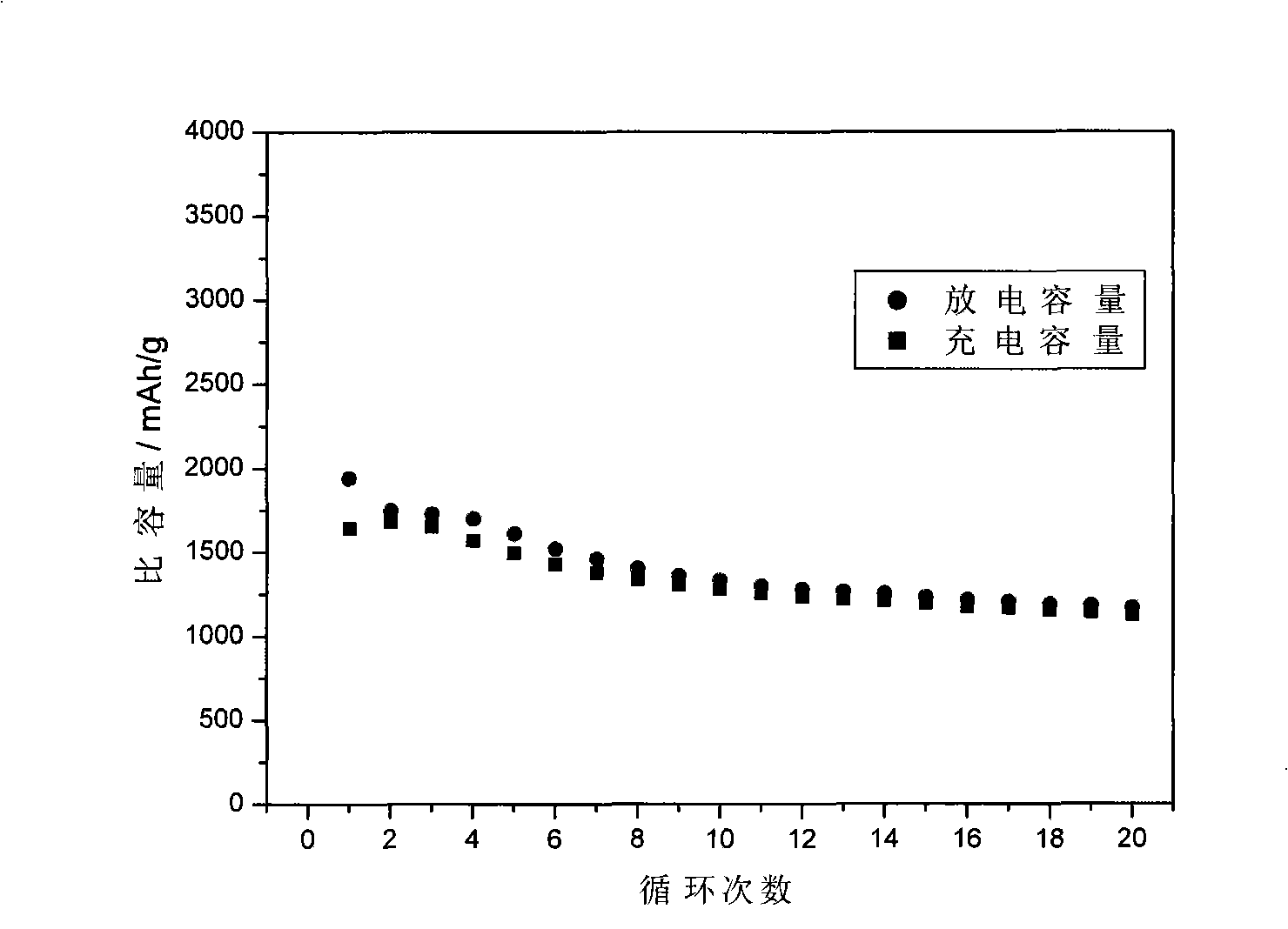

[0037] The prepared lithium-ion battery negative electrode was assembled into a lithium-ion battery for charging and discharging tests. The charging and discharging curves of the first three times were as follows: figure 2 As shown, the capacity-cycle number curve of the first 20 cycles is as follows image 3 shown. Its first ...

Embodiment 2

[0039] (1) Mix and stir 0.85g carbon-coated silicon with 0.05g conductive carbon black, 5g styrene-butadiene rubber-carboxymethylcellulose sodium emulsion (solid content 2wt%) for 8 hours, and then apply to 20 micron thick porous poly On the surface of the vinyl film, vacuum-dry at 50°C for 10 hours to obtain a carbon-coated silicon layer;

[0040] (2) 0.88g acetylene black and 6g styrene-butadiene rubber-carboxymethylcellulose sodium emulsion (solid content 2wt%) were mixed and stirred for 6 hours, then uniformly sprayed onto the surface of the carbon-coated silicon layer, and dried in vacuum at 40°C for 12 hours , to obtain a lithium ion battery negative electrode.

[0041] The prepared lithium-ion battery negative electrode was assembled into a lithium-ion battery for charging and discharging tests. The first charge-discharge coulombic efficiency was 88%, and the reversible capacity after 20 cycles was 1000mAh / g.

Embodiment 3

[0043] (1) Mix and stir 0.85g of carbon-coated silicon with 0.05g of conductive carbon black and 5ml of polyvinylidene fluoride in 1-methyl-2-pyrrolidone (concentration: 0.02g / ml) for 8 hours, and then apply to 20 microns On the surface of a thick porous polyethylene film, dry it in vacuum at 40°C for 12 hours to obtain a carbon-coated silicon layer;

[0044] (2) Mix and stir 0.88g acetylene black and 6ml polyvinylidene fluoride in 1-methyl-2-pyrrolidone solution (concentration 0.02g / ml) for 4 hours, and then apply it to the surface of the carbon-coated silicon layer. vacuum drying for 12 hours to obtain a lithium ion battery negative electrode.

[0045] The prepared lithium-ion battery negative electrode was assembled into a lithium-ion battery for charging and discharging tests. The first charge-discharge coulombic efficiency was 55%, and the reversible capacity after 20 cycles was 900mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com