Method for detecting chrome in milk and dairy product

A detection method and technology of dairy products, applied in the field of analysis, can solve the problems of large amount of reagents, slow test speed, insufficient sensitivity, etc., and achieve the effect of simple detection steps, less reagent consumption and strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Selection of instrument parameters for graphite furnace atomic absorption spectrophotometer detection of chromium content.

[0039] 1. Reagents and instruments:

[0040] 1) Preparation of standard solution:

[0041] Precisely draw 1.0mg / ml (GBW(E)080117, National Standard Material Research Center), and use ultrapure water to make up the volume in a 100mL volumetric flask, and mix well to obtain a standard stock solution with a chromium standard solution concentration of 100ng / mL. Store in a -18°C freezer away from light for at least 4 weeks. When in use, dilute with 5% nitric acid to 10.0ng / mL, 8.0ng / mL, 6.0ng / mL, 4.0ng / mL, 2.0ng / mL standard solution.

[0042] 2) Instrument: Hitachi Z-2000 Atomic Absorption Graphite Furnace Spectrophotometer

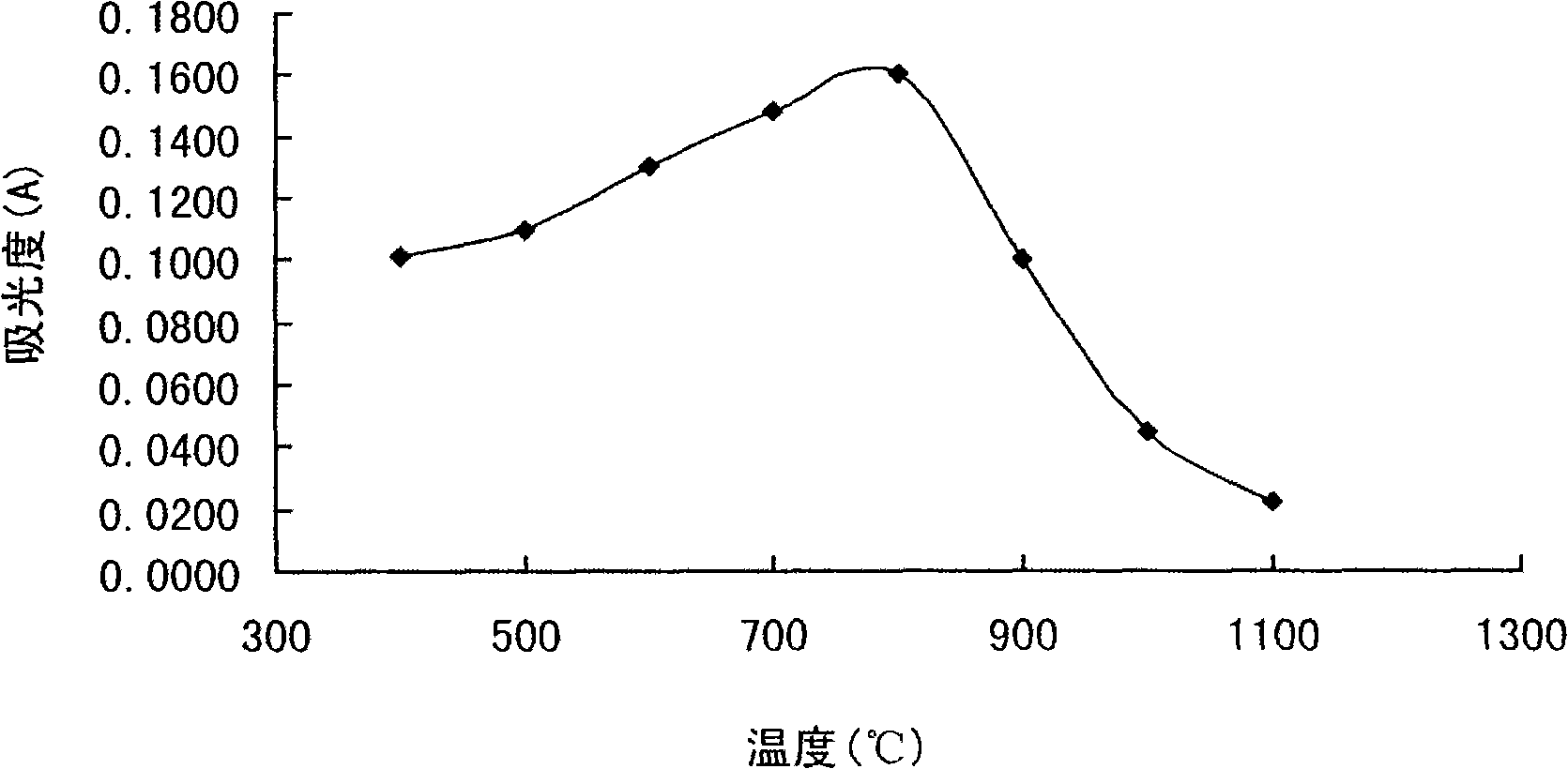

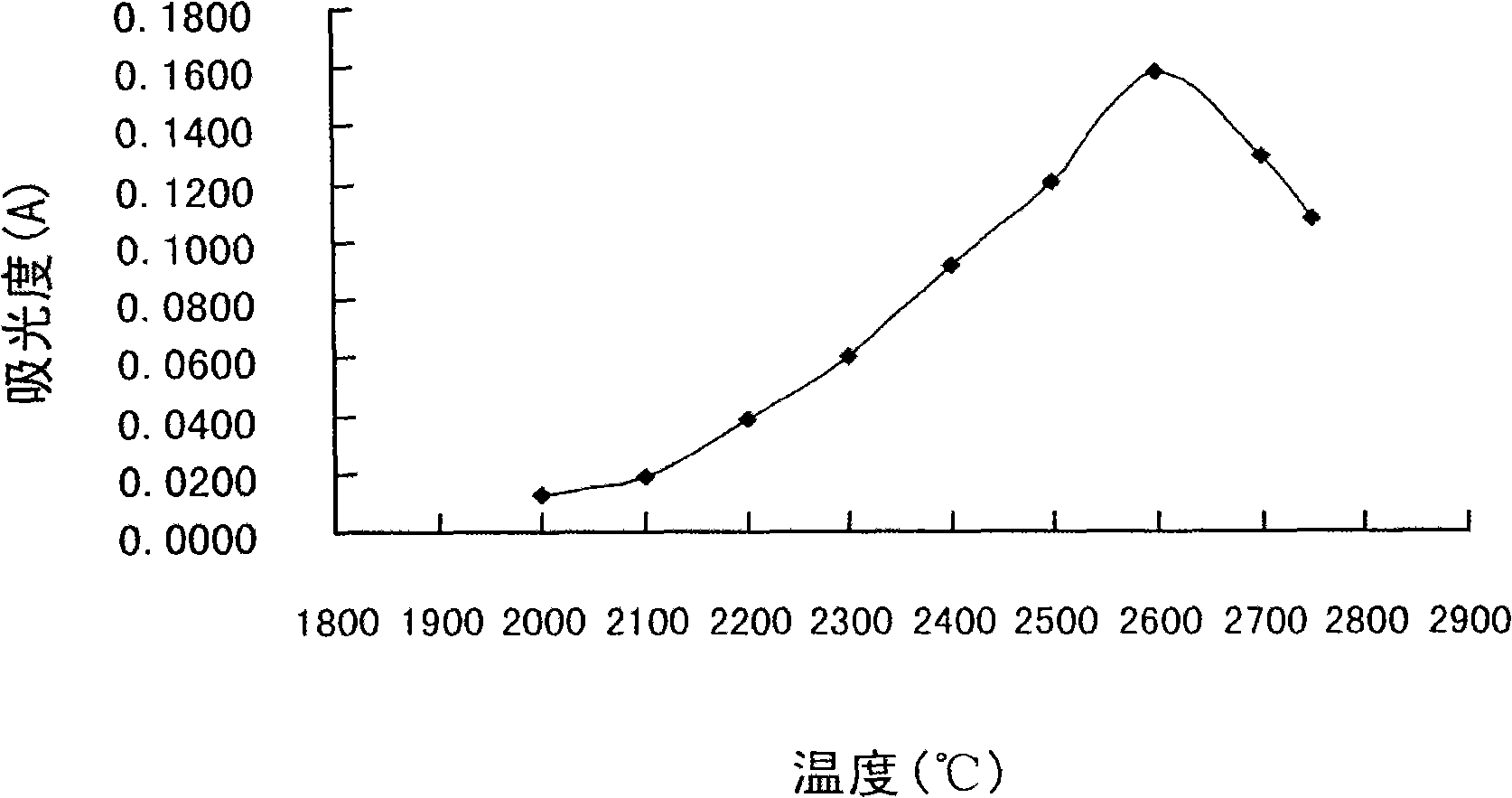

[0043] 2. Selection of drying program

[0044] It is easy to bump and sputter when the sample is dried to about 100°C, so first dry most of the free water at 50°C, and then heat it to 140°C in a ramp manner and keep ...

Embodiment 2

[0064] Example 2 A graphite furnace atomic absorption spectrophotometer was used to measure the content of chromium in milk.

[0065] 1) Preparation of standard solution:

[0066] Precisely draw 1.0mg / ml (GBW(E)080117, National Standard Materials Research Center), and use ultrapure water to make up the volume in a 100mL volumetric flask, and mix well to obtain a standard stock solution with a chromium standard solution concentration of 100ng / mL. Store in a -18°C freezer away from light for at least 4 weeks. When in use, dilute with 5% nitric acid to 10.0ng / mL, 8.0ng / mL, 6.0ng / mL, 4.0ng / mL, 2.0ng / mL standard solution.

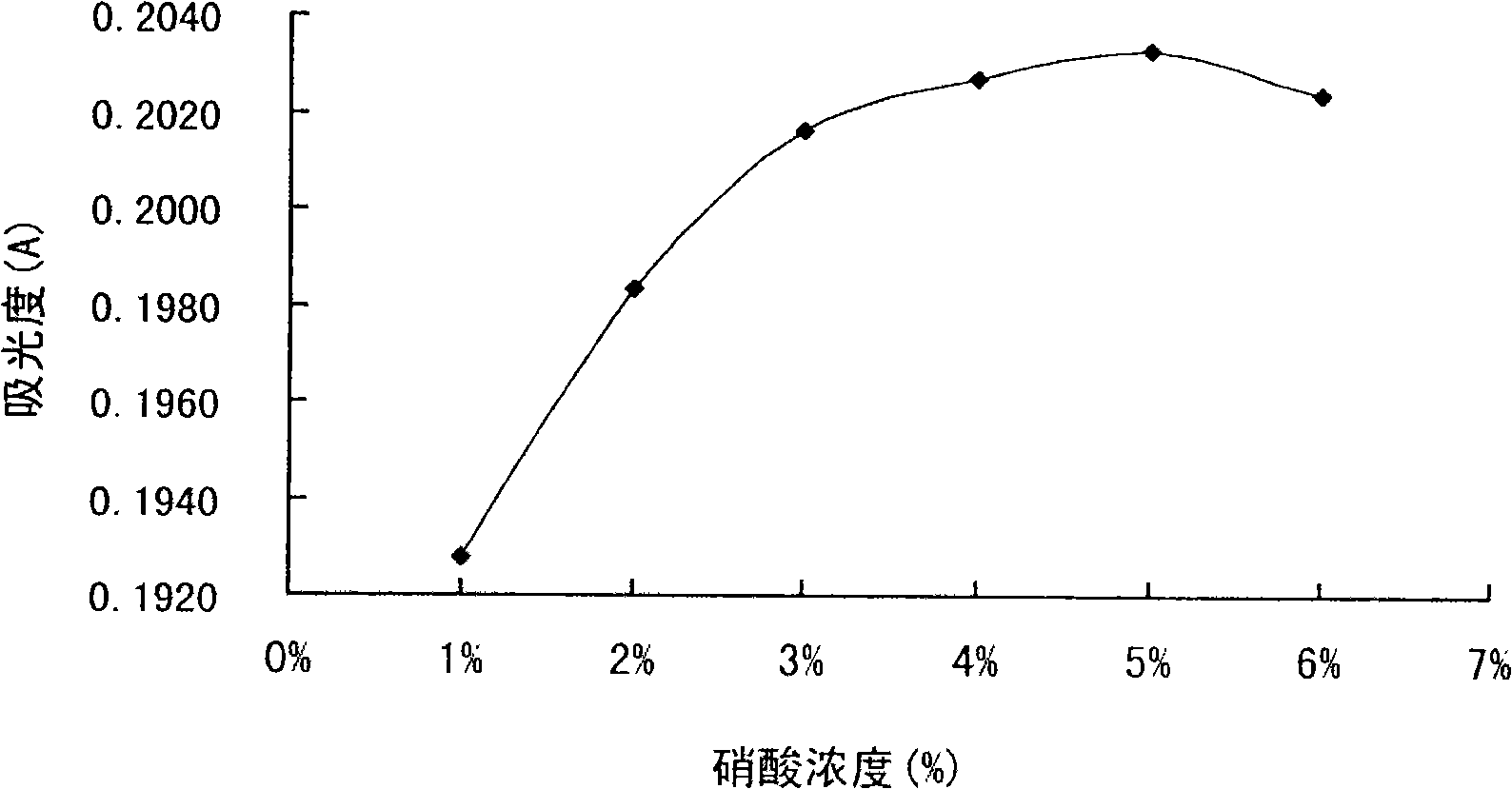

[0067] 2) Preparation of reagents:

[0068] Preparation of 5% nitric acid: Measure 25.00mL of concentrated nitric acid (premium pure), slowly pour it into a beaker with about 200mL of pure water, transfer it to a 500mL volumetric flask after cooling, dilute to volume with pure water, mix well, and set aside .

[0069] 3) Sample preparation:

[0070] Weigh 4...

Embodiment 3

[0086] Example 3 Determination of chromium content in milk by using an atomic absorption graphite furnace spectrophotometer.

[0087] 1) Preparation of standard solution:

[0088] Precisely draw 1.0mg / ml (GBW(E)080117, National Standard Material Research Center), and use ultrapure water to make up the volume in a 100mL volumetric flask, and mix well to obtain a standard stock solution with a chromium standard solution concentration of 100ng / mL. Store in a -18°C freezer away from light for at least 4 weeks. When in use, dilute with 5% nitric acid to 10.0ng / mL, 8.0ng / mL, 6.0ng / mL, 4.0ng / mL, 2.0ng / mL standard solution.

[0089] 2) Preparation of reagents:

[0090] (a) Preparation of 5% nitric acid:

[0091] Measure 25.00mL of concentrated nitric acid (high-grade pure), slowly pour it into a beaker with about 200mL of pure water, transfer it to a 500mL volumetric flask after cooling, make up to volume with pure water, mix well, and set aside.

[0092] 3) Sample preparation:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com