Swaddling clothes facing anti-crease shrink-proof finishing process

A shrink-resistant finishing and fabric technology, applied in fiber treatment, physical treatment, biochemical fiber treatment, etc., can solve problems such as environmental pollution and human health threats, improve friction factor, improve anti-wrinkle and anti-shrink performance, and have strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

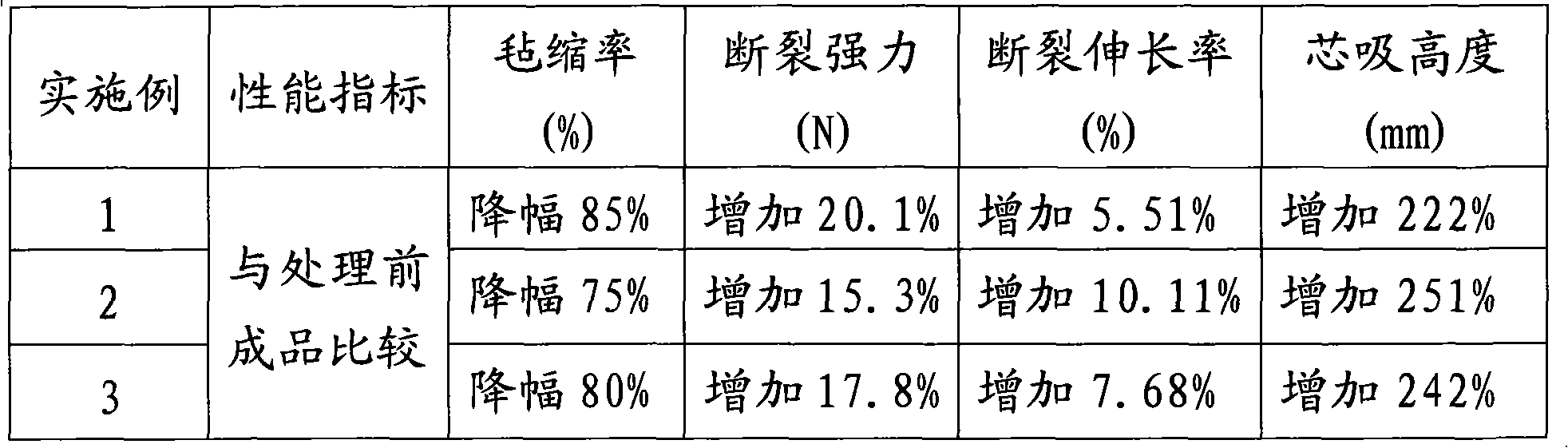

Examples

Embodiment 1

[0021] (1) The sweater fabric is subjected to plasma pretreatment in a plasma apparatus, wherein the reaction gas is oxygen, the treatment time is 5 minutes, the treatment pressure is 50Pa, and the treatment power is 125W;

[0022] (2) Treat the sweater fabric after plasma pretreatment with transglutaminase, wherein the concentration of transglutaminase is 3% (o.w.f), the treatment temperature is 30°C, and the treatment time is 50 minutes, The treatment bath ratio is 1:15;

[0023] (3) Rinse the sweater fabric obtained in the above step (2) with clear water, and dry naturally to obtain the finished product.

Embodiment 2

[0025] (1) The sweater fabric is subjected to plasma pretreatment in a plasma apparatus, wherein the reaction gas is nitrogen, the treatment time is 8 minutes, the treatment pressure is 40Pa, and the treatment power is 150W;

[0026] (2) Treat the sweater fabric after plasma pretreatment with transglutaminase, wherein the concentration of transglutaminase is 4% (o.w.f), the treatment temperature is 40°C, and the treatment time is 30 minutes, The treatment bath ratio is 1:18;

[0027] (3) Rinse the sweater fabric obtained in the above step (2) with clear water, and dry naturally to obtain the finished product.

Embodiment 3

[0029] (1) The sweater fabric is subjected to plasma pretreatment in a plasma apparatus, wherein the reaction gas is argon, the treatment time is 10 minutes, the treatment pressure is 30Pa, and the treatment power is 100W;

[0030] (2) treating the sweater fabric after plasma pretreatment with transglutaminase, wherein the concentration of transglutaminase is 5% (o.w.f), the treatment temperature is 45°C, and the treatment time is 40 minutes, The treatment bath ratio is 1:20;

[0031] (3) Rinse the sweater fabric obtained in the above step (2) with clear water, and dry naturally to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com