Preparation of organic inorganic composite phase-change material

A technology of inorganic composite and phase change materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of the influence of the phase change potential of inorganic-organic composite phase change materials, the easy fragmentation of porous media, and the reduction of adsorption capacity , to achieve the effect of streamline operation and industrialized production, easy control of the operation process, and maintenance of integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

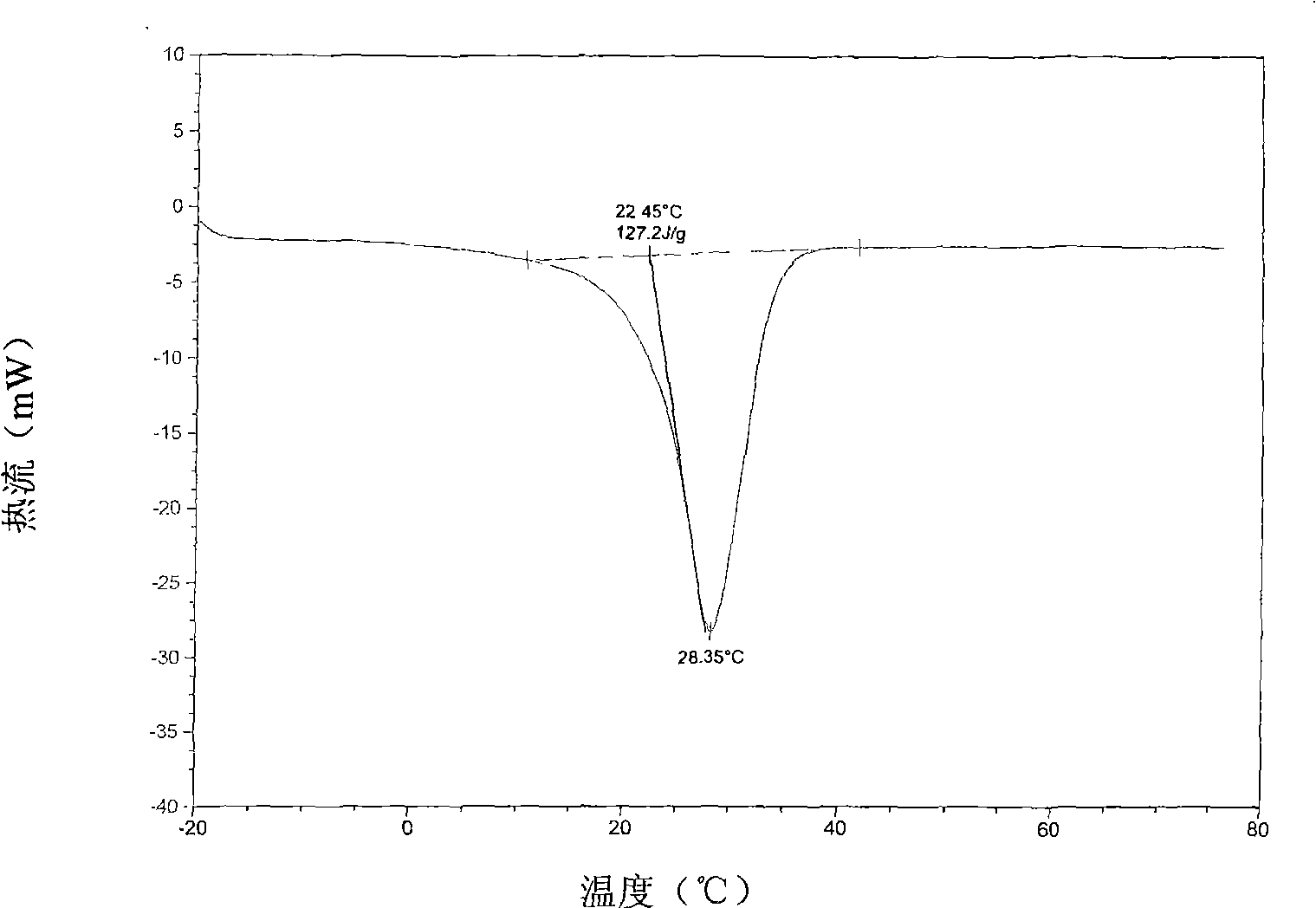

[0039] In this embodiment, the inorganic porous mineral carrier is expanded perlite with a particle size of 3-5mm; the organic phase-change material is paraffin (solid), its phase-change enthalpy is 180-220J / g, and its phase-change temperature is 25-30°C.

[0040] The preparation process is:

[0041] First, add 20 grams of expanded perlite of 3 to 5mm into the vacuum reactor. The temperature of the water bath in the vacuum reactor is controlled at about 80°C. Open the liquid feed valve and add 20 grams of paraffin (heat first to make it liquid) and stir; after 3 minutes, open the exhaust valve to pump the vacuum reactor to a negative pressure of 0.095MPa, and continue stirring to make the paraffin completely covered by the expanded perlite Adsorption; After 10 minutes, stop the reaction, close the pumping valve and open the inlet valve, wait until the reactor is under normal pressure and open the discharge valve to obtain 40 grams of the composite phase change material of expa...

Embodiment 2

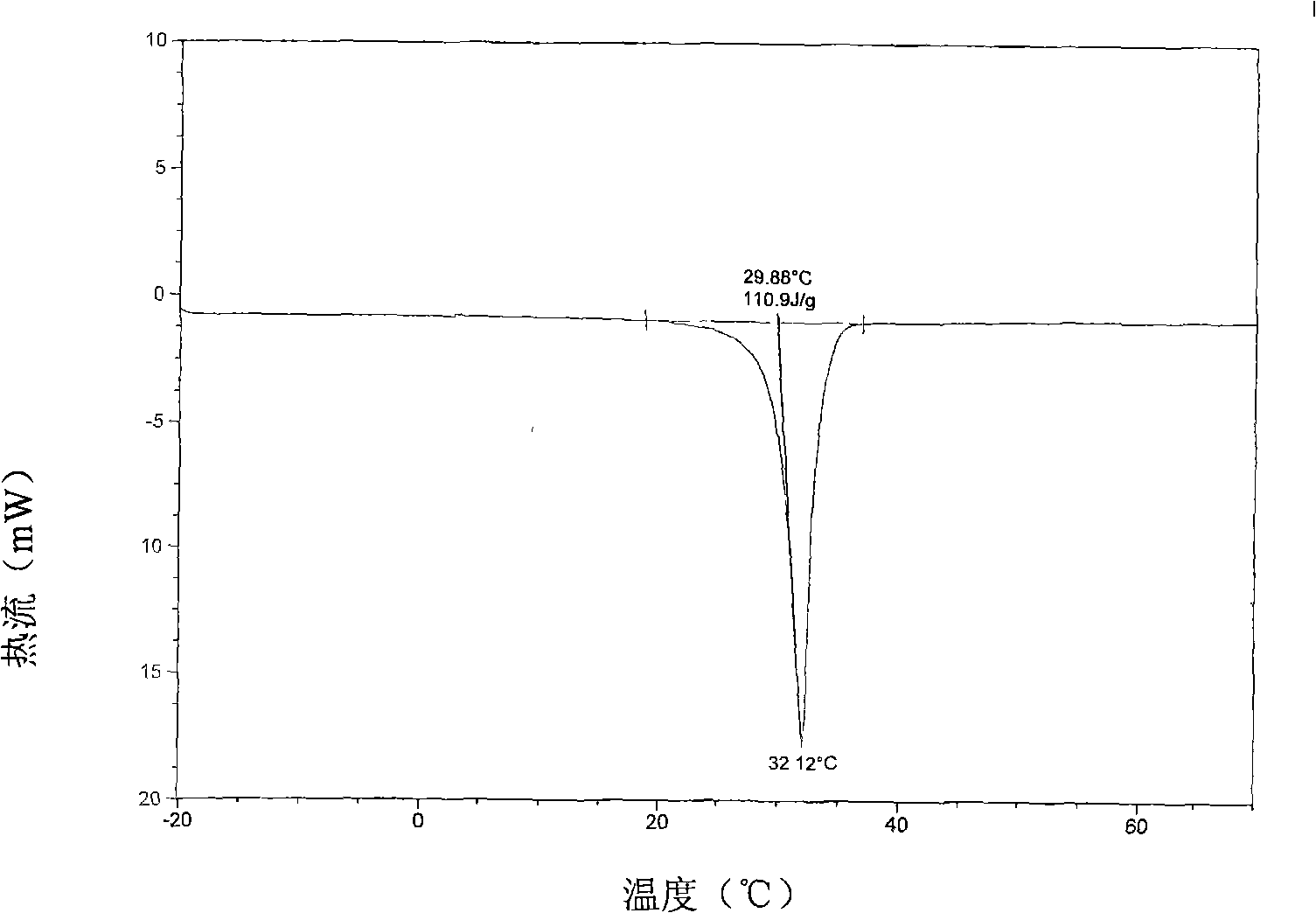

[0051] In this embodiment, the inorganic porous mineral carrier is expanded perlite with a particle size of 3 to 5 mm; the organic phase change material is a mixed phase change material of liquid paraffin and octadecane (the weight ratio of liquid paraffin and octadecane is 1:8) , its phase change enthalpy is 178~204J / g, and the phase change temperature is 27~35°C.

[0052] The preparation process is:

[0053] First, add 20 grams of expanded perlite to the vacuum reactor. The temperature of the water bath in the vacuum reactor is controlled at about 80 ° C. Then, the vacuum reactor is evacuated to a negative pressure of 0.05 MPa, and the pumping valve is closed and the liquid feed valve is opened at the same time. Add a mixture of 35 grams of liquid paraffin and octadecane and stir; after 3 minutes, open the exhaust valve to pump the vacuum reactor to a negative pressure of 0.095MPa, and continue stirring to make the liquid paraffin and octadecane fully absorbed by the expande...

Embodiment 3

[0057] In this embodiment, the inorganic porous mineral carrier is sepiolite, with a particle size of 0.5-1 mm; the organic phase change material is a mixed phase change material of liquid paraffin and octadecane (the weight ratio of liquid paraffin and octadecane is 1:5) , its phase change enthalpy is 167~192J / g, and the phase change temperature is 25~35°C.

[0058] The preparation process of the composite material is the same as in Example 2.

[0059] The product of this example is detected with the same method as in Example 1, the result: observation and analysis under an optical microscope, the organic material (the mixture of liquid paraffin and octadecane) has completely entered the pores of the sepiolite particles, and the composite material particles The integrity is good, the particle size is 0.2-0.5mm, the particle size change rate is 20-40%, the adsorption amount of organic materials reaches 50% and the adsorption amount is stable, the phase change enthalpy is 80-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Phase change enthalpy | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com