Storage yard protection method based on sulfate reducing bacteria and biomass

A biomass and sulphate technology, applied to the removal of solid waste, restoration of polluted soil, etc., can solve the problems of poor durability of adhesives, complex proportioning, and high demand for materials, and achieve short construction period and simple process flow , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

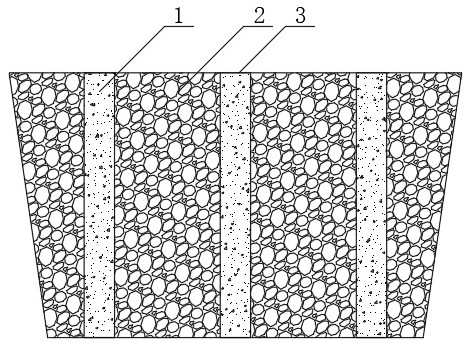

[0045] The storage yard protection method based on sulfate-reducing bacteria and biomass includes the following steps:

[0046] S1, drying and crushing the straw to obtain straw granules;

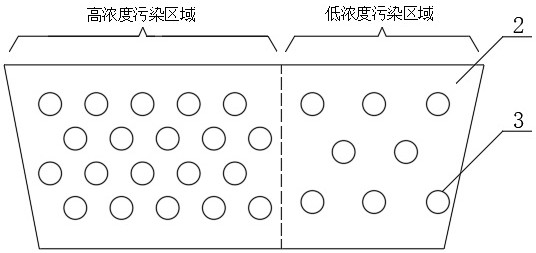

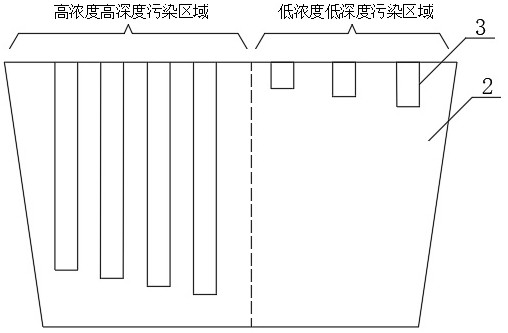

[0047] S2. Measure the concentration of heavy metals in the storage yard 1, and determine the high pollution area, low pollution area and pollution depth of the storage yard;

[0048]S3. According to the pollution situation of the storage yard, densely arrange the points in the high-pollution area of the storage yard with a spacing of 3m, and loosely arrange the points in the low-pollution area with a spacing of 30m and a diameter of 10cm for drilling holes;

[0049] S4. Inject the mixture 3 of sulfate-reducing bacteria and straw crumbs into the hole 2, the volume-to-mass ratio of sulfate-reducing bacteria and straw crumbs is 1L:1kg, and the bacterial concentration of sulfate-reducing bacteria is 1×10 4 ~1×10 8 cfu / ml;

[0050] Through field tests, the heavy metal content in the test f...

Embodiment 2

[0052] The storage yard protection method based on sulfate-reducing bacteria and biomass includes the following steps:

[0053] S1, the coconut shell is dried and crushed to obtain coconut shell granules;

[0054] S2. Measure the concentration of heavy metals in the storage yard 1, and determine the high pollution area, low pollution area and pollution depth of the storage yard;

[0055] S3. According to the pollution situation of the storage yard, densely arrange the points in the high-pollution area of the storage yard with a spacing of 10m, and loosely arrange the points in the low-pollution area with a spacing of 100 points and a diameter of 25cm for drilling holes;

[0056] S4. Inject the mixture 3 of sulfate-reducing bacteria and coconut shell granules into the hole 2, the volume-to-mass ratio of sulfate-reducing bacteria and coconut shell granules is 1L:5kg, and the concentration of sulfate-reducing bacteria is 1×10 4 ~1×10 8 cfu / ml;

[0057] Through field tests, t...

Embodiment 3

[0059] The storage yard protection method based on sulfate-reducing bacteria and biomass includes the following steps:

[0060] S1, the leaves are dried and crushed to obtain leaf fragments;

[0061] S2. Measure the concentration of heavy metals in the storage yard 1, and determine the high pollution area, low pollution area and pollution depth of the storage yard;

[0062] S3. According to the pollution situation of the storage yard, densely arrange the points in the high-pollution area of the storage yard with a spacing of 20m, and loosely arrange the points in the low-pollution area with a spacing of 200m and a diameter of 50cm for drilling holes;

[0063] S4. Inject the mixture 3 of sulfate-reducing bacteria and leaf fragments into the hole 2, the volume-to-mass ratio of sulfate-reducing bacteria and leaf fragments is 1L:5kg, and the bacterial concentration of sulfate-reducing bacteria is 1×10 4 ~1×10 8 cfu / ml;

[0064] Through field tests, the heavy metal content in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com