Sol-solvent-thermal method for synthesizing nanocrystalline oxide powder

A technology of oxide powder and nanocrystals, which is applied in chemical instruments and methods, titanium oxide/hydroxide, oxide/hydroxide preparation, etc., to achieve the effects of controllable size, low raw material cost, and good crystal shape development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

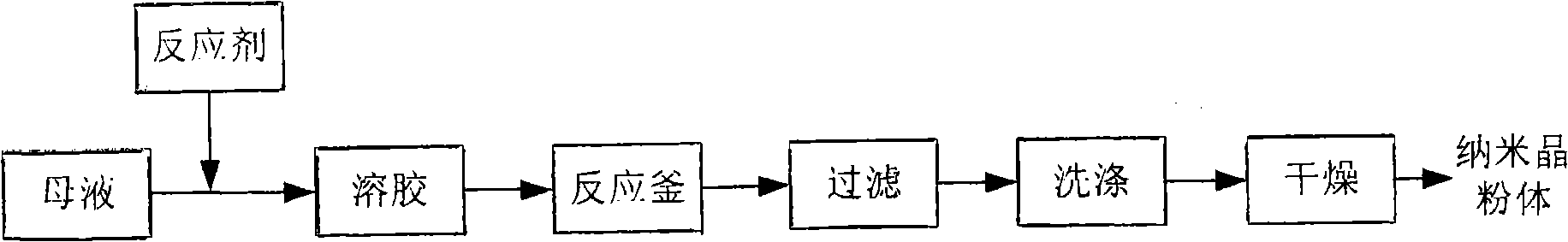

[0030] (3) Preparation of sol (sol): at a certain temperature, under stirring, the prepared reactant solution is slowly added dropwise to the prepared inorganic salt mother liquor, and after the addition is completed, the reaction is continued for a period of time to obtain a transparent Sol;

[0031] (4) Solvothermal reaction of the sol: the prepared sol is placed in a reaction kettle, reacted at a certain temperature and pressure for a suitable time, and the formed product is filtered, washed and dried to obtain a nanocrystalline oxide powder.

Embodiment 1

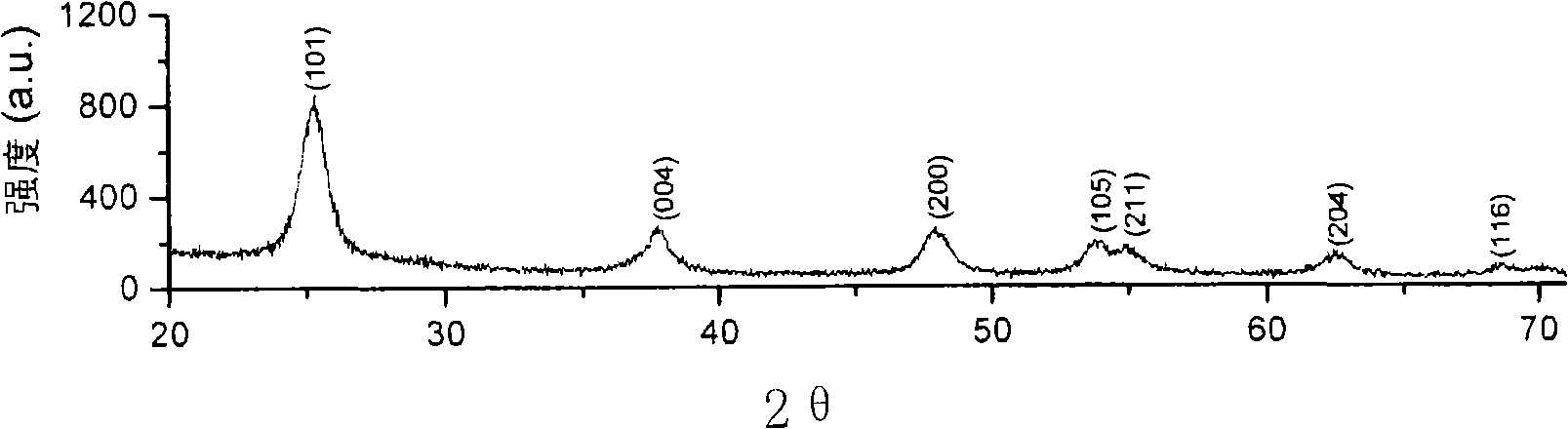

[0033] Weigh 3.113g TiCl 4 , carefully added to 50mL of ethanol at 0°C, and then 50mL of ethylene glycol, and stirred thoroughly to obtain a 0.164mol / L titanium salt mother liquor. Weigh 2.725g of concentrated ammonia water (wt%=25-28%, the same below) and 0.5g of polyvinylpyrrolidone (PVP), and sequentially add them into 30mL of ethanol to prepare a 1.4mol / L precipitation reagent solution. Place the mother liquor in a constant temperature water bath at 80°C and stir it fully; after preheating for 5 minutes, slowly drop the precipitation reagent solution into the mother liquor at a rate of about 1 mL / min; after the precipitation reagent solution is added dropwise, continue to The temperature was reacted for 30 min, and finally a clear and transparent colorless sol was obtained. Measure 40mL of sol, put it in a self-pressurized reactor with a volume of 50mL, and react at a temperature of 150°C, a pressure of 1MPa, and a time of 3h. After the reaction, the reaction kettle was ...

Embodiment 2

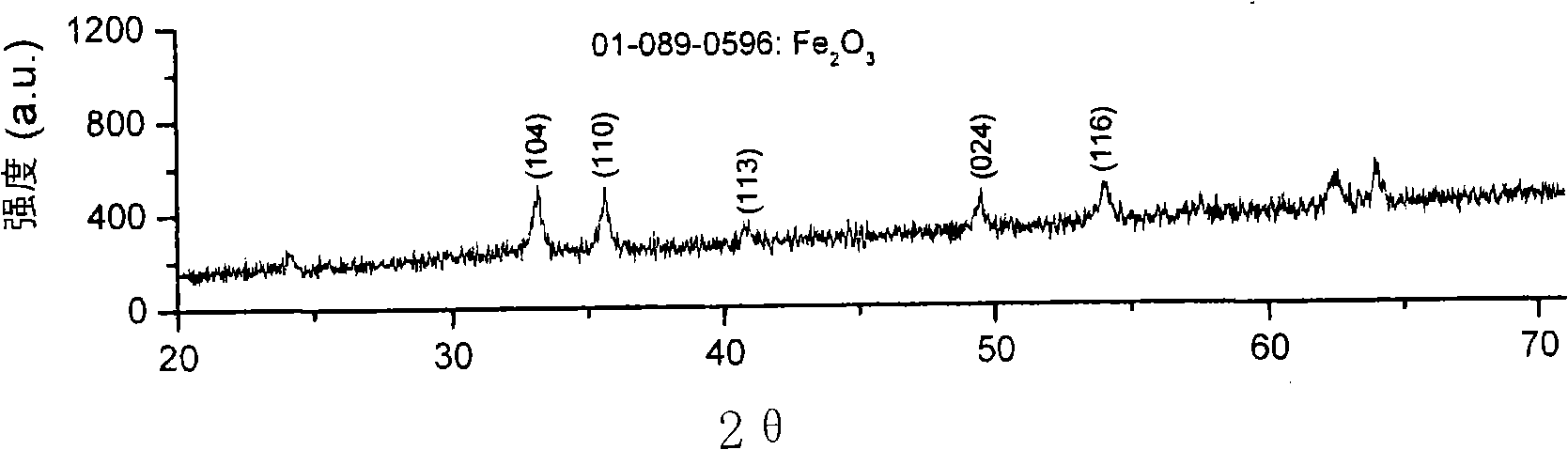

[0035] Weigh 2.0g FeCl 3 ·6H 2 O, join in 50mL ethanol, add 50mL glycerol again, and fully stir, obtain the iron salt mother liquor of 0.074mol / L. Weigh 0.970g of concentrated ammonia water and 0.2g of polyvinylpyrrolidone (PVP), and add them to 30mL of ethanol in sequence to prepare a 0.5mol / L precipitant solution. Place the mother liquor in a constant temperature water bath at 80°C and stir it fully; after preheating for 5 minutes, slowly drop the precipitation reagent solution into the mother liquor at a rate of about 1 mL / min; after the precipitation reagent solution is added dropwise, continue to The temperature was reacted for 30 min, and finally a clear and transparent brown-yellow sol was obtained. Measure 40mL of sol, put it in a self-pressurized reactor with a volume of 50mL, and react at a temperature of 150°C, a pressure of 1MPa, and a time of 3h. After the reaction, the reaction kettle was naturally cooled to room temperature, and the slurry was taken out, cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com