Terminal structure for preventing tin climbing

A terminal structure and terminal technology, used in fixed connections, electrical components, circuits, etc., can solve problems such as blockage, aggregation, increase in product rejection rate, and large volume, and achieve the effect of preventing tin creep and avoiding short circuits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

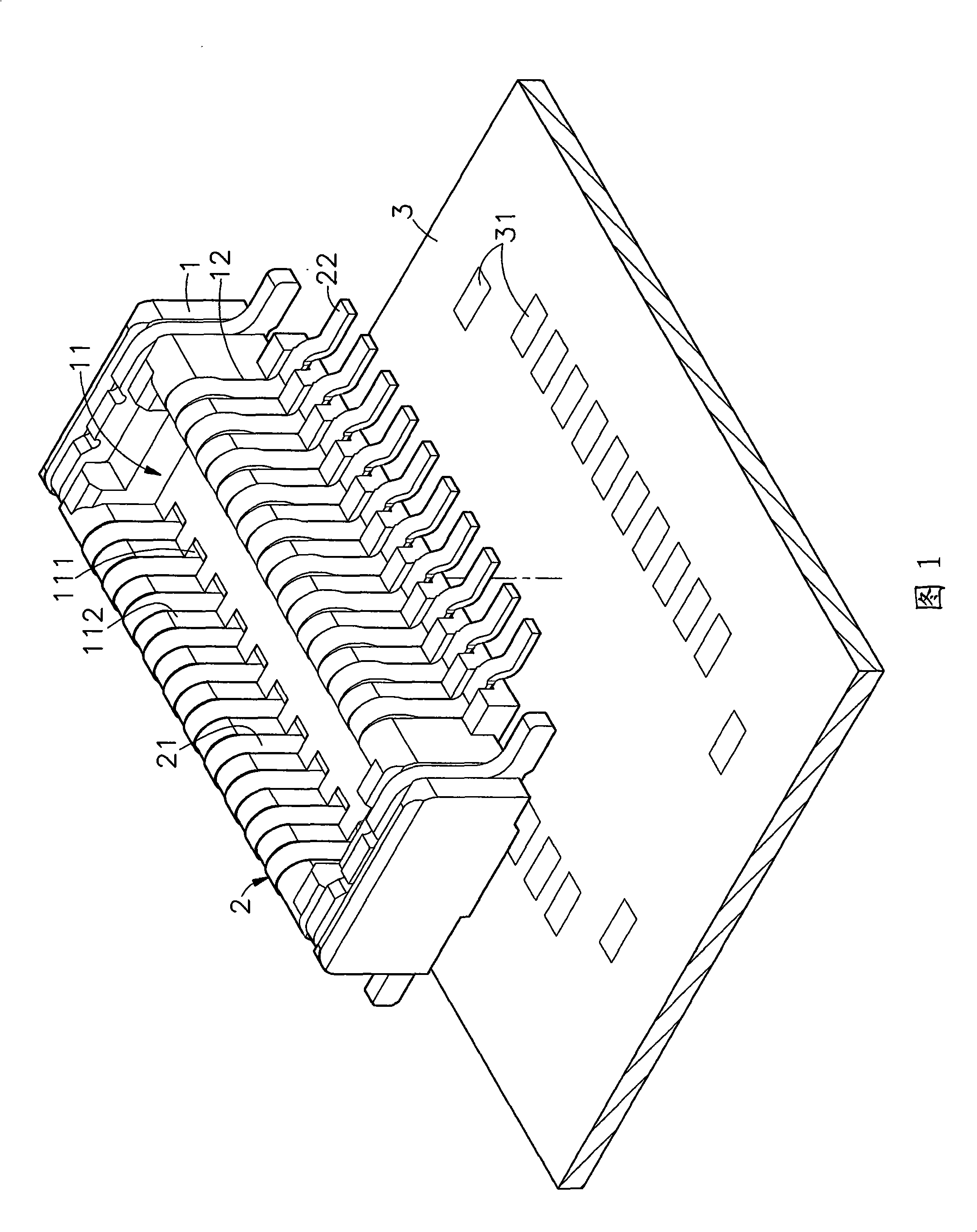

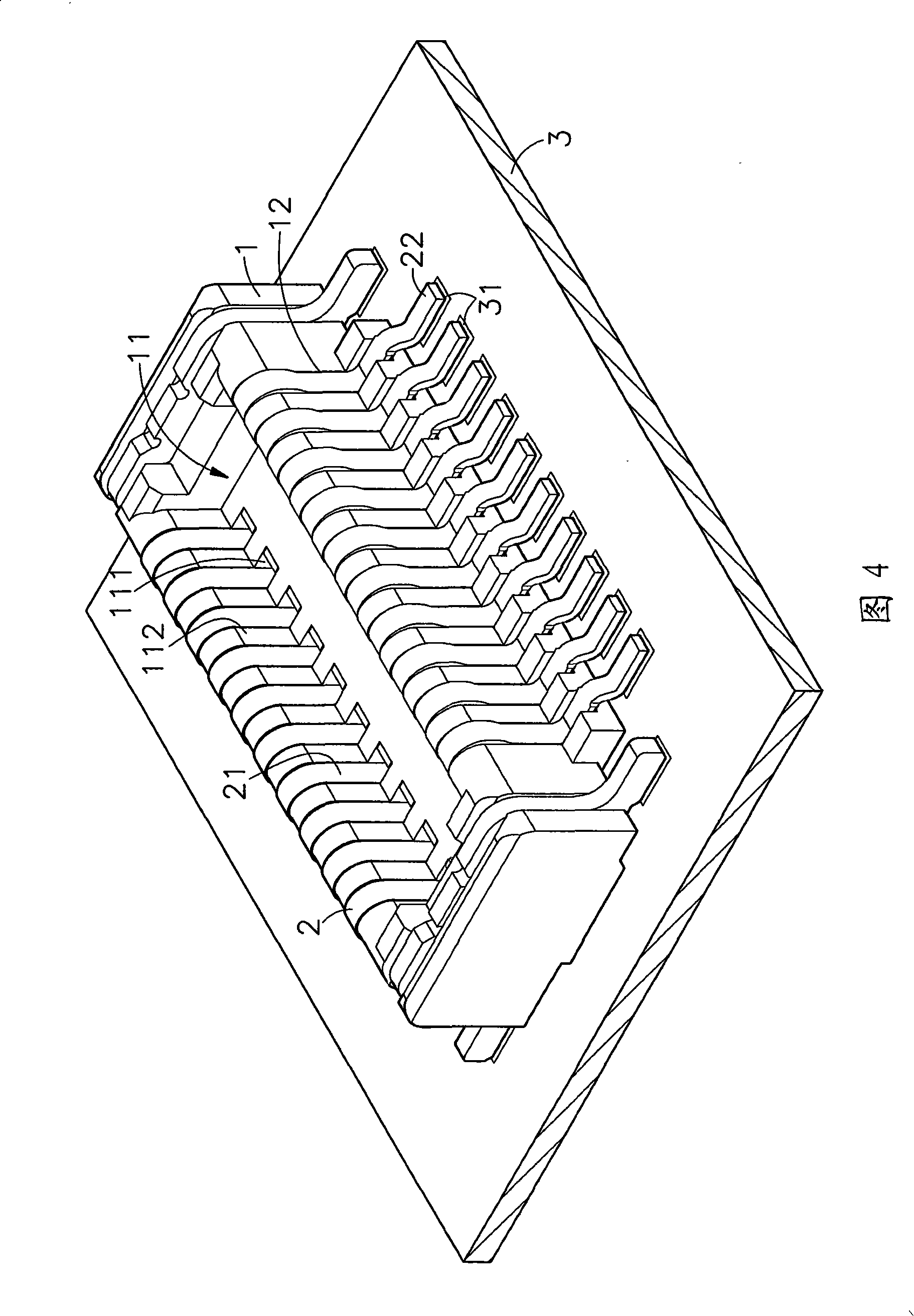

[0034] Please refer to Figures 1 to 3, which are three-dimensional exploded views, side sectional views before etching, and side sectional views after etching of the present invention. It can be clearly seen from the figures that the terminal structure of the present invention is It consists of an insulating base body 1, several terminals 2, etc., among which:

[0035]The insulating seat body 1 has an accommodating space 11 inside, and several slots 111 are arranged in the accommodating space 11, and the wall surface 112 of the accommodating space 11 faces the insulating seat with respect to the several slots 111. The exterior of the body 1 is respectively provided with several clamping grooves 12 .

[0036] The plurality of terminals 2 are provided with a butt joint portion 21 , and a welding portion 22 extends from the butt joint portion 21 to the other side.

[0037] When the above-mentioned components are assembled, several slots 111 in the accommodation space 11 of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com