Fiber-reinforced composite material rib concrete pile and its production and construction method

A composite material and concrete pile technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems of not achieving satisfactory results, increase project cost, increase technical difficulty, etc., to reduce cost and technical difficulty, and improve service. Years, the effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] A kind of FRP concrete pile of the present invention, its structural composition is as follows:

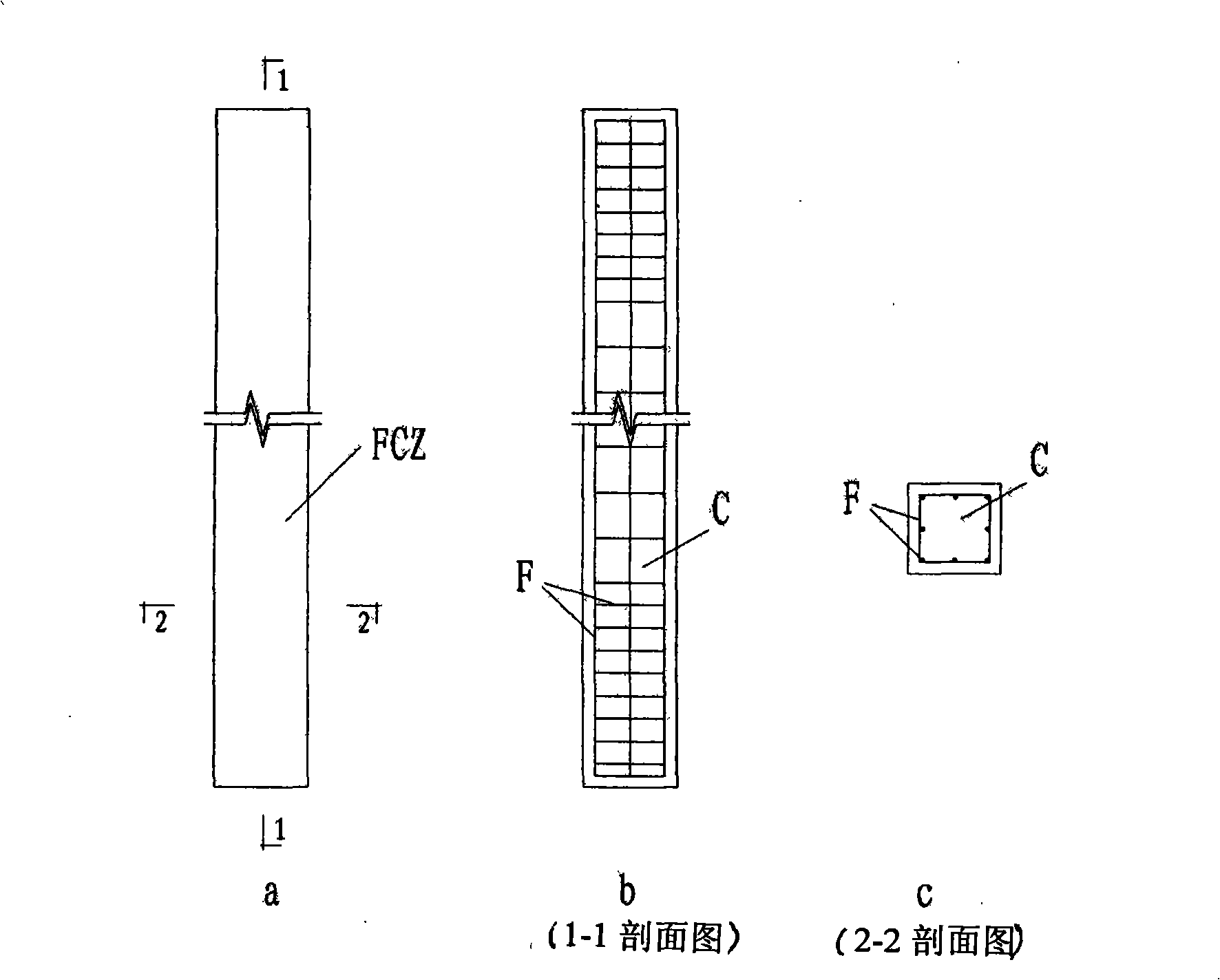

[0087] FRP concrete pile is composed of base material C and reinforcement (or profile) F, such as figure 1 As shown; the arrangement of FRP reinforcement adopts the arrangement of prefabricated reinforced concrete square piles; the connection method of C and F adopts the connection method of cementation, friction and occlusion, which is the same as the connection method between steel bar (or section steel) and concrete.

[0088] The base material F is C40 concrete.

[0089] Boron fiber is selected as the reinforced FRP material, and its parameter index is: density--2400~2650kg / m 3 ; Tensile strength - 3200 ~ 5200MPa; Modulus - 350 ~ 400GPa.

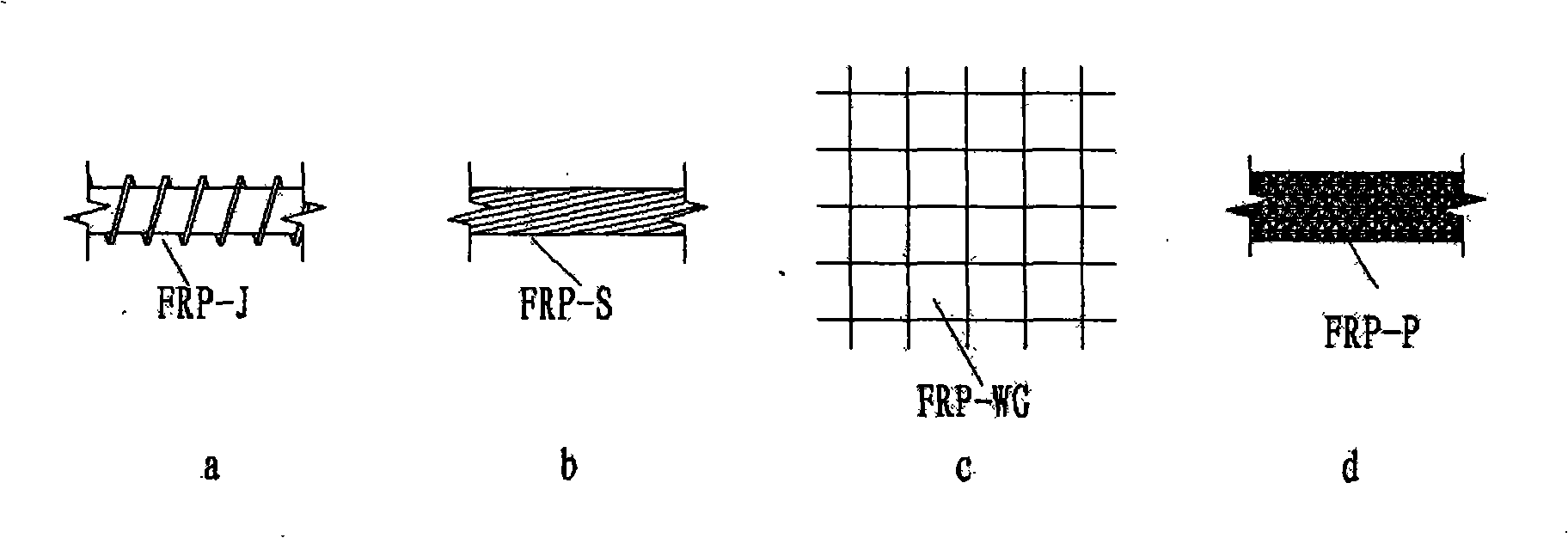

[0090] For FRP concrete piles, the boron fiber ribbed bars used are rods (bars), such as figure 2 As shown in FRP-J; its surface is with various uneven patterns (ribs), such as Figure 4 shown in S-DL.

[0091] FRP concrete pile,...

Embodiment 2

[0095] A kind of FRP concrete pile of the present invention, its structural composition is as follows:

[0096] FRP concrete pile is composed of base material C and reinforcement (or profile) F, such as figure 1 As shown; the arrangement of FRP reinforcement adopts the arrangement of prefabricated steel plate with concrete pipe pile; the connection method of C and F adopts the connection method of cementation, friction and occlusal, which is the same as the connection method between steel bar (or section steel) and concrete .

[0097] The base material is C60 concrete.

[0098] The reinforced FRP material is a material of high modulus carbon fiber, and its parameter index is: density--1750kg / m 3 ; Tensile strength - 2400MPa; Modulus - 350GPa.

[0099] For FRP concrete piles, the high modulus carbon fiber cloth used is a sheet (cloth), such as figure 2 As shown in FRP-P; its surface is with various uneven patterns (indentations), such as Figure 5 Shown in S-YH.

[0100]...

Embodiment 3

[0104] A kind of FRP concrete pile of the present invention, its structural composition is as follows:

[0105] FRP concrete pile is composed of base material C and reinforcement (or profile) F, such as figure 1 As shown; the arrangement of FRP reinforcement adopts the arrangement of cast-in-place concrete piles; the connection method of C and F adopts the connection method of cementation, friction, and occlusal, which is the same as the connection method between steel bars (or steel bars) and concrete.

[0106] The base material is C20 concrete.

[0107] The reinforced FRP material is made of ordinary carbon fiber, and its parameter index is: density--1750kg / m 3 ; Tensile strength - 3000MPa; Modulus - 230GPa.

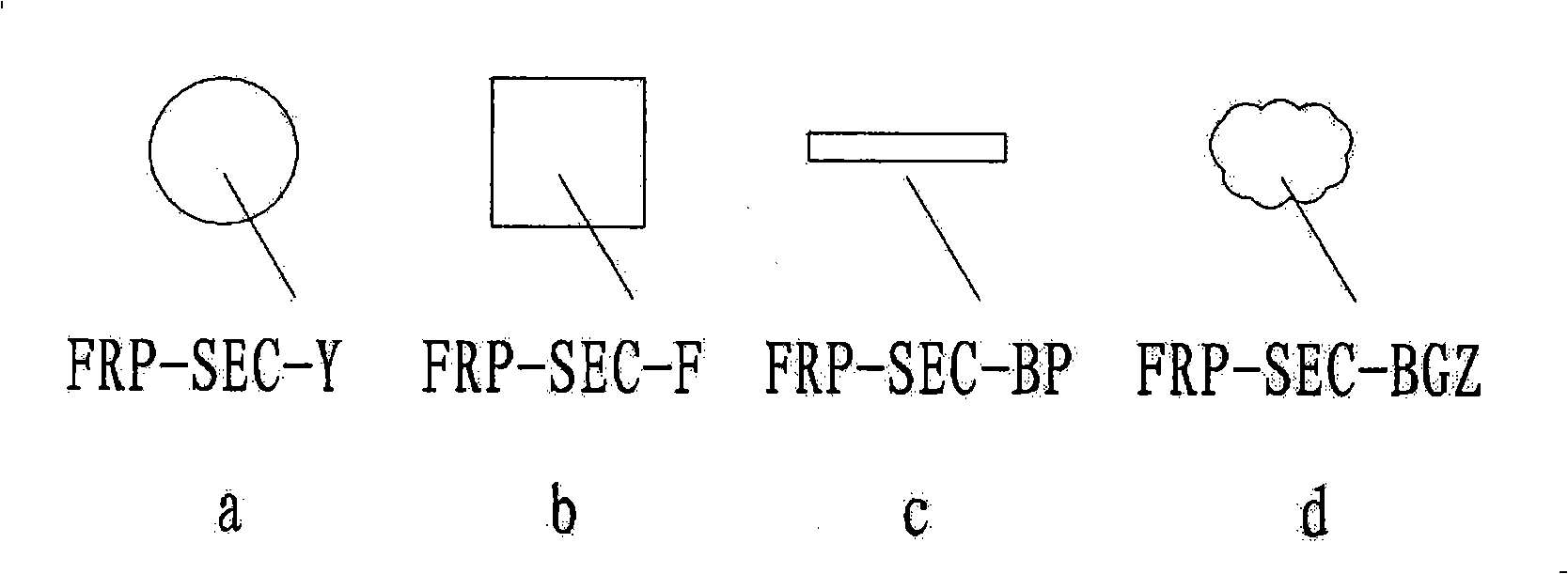

[0108] For FRP concrete piles, the common carbon fiber (CFRP) ribbed bars used are bars (bars), such as figure 2 Shown in FRP-J; square cross-section, such as image 3 As shown in FRP-SEC-F; its surface is with various uneven patterns (ribs), such as Figure 4 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com