Electric coupling apparatus of hybrid power machine with dual-coupling mode

A hybrid, electromechanical coupling technology, which is applied in the arrangement of multiple different prime movers of power plants, pneumatic power plants, and general power plants, etc. It takes into account the fuel economy, power and drivability of the whole vehicle, and achieves the effect of convenient space layout, simple and compact structure, and small volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] This embodiment is used to explain the claims, and the protection scope of the present invention is not limited to the following structures.

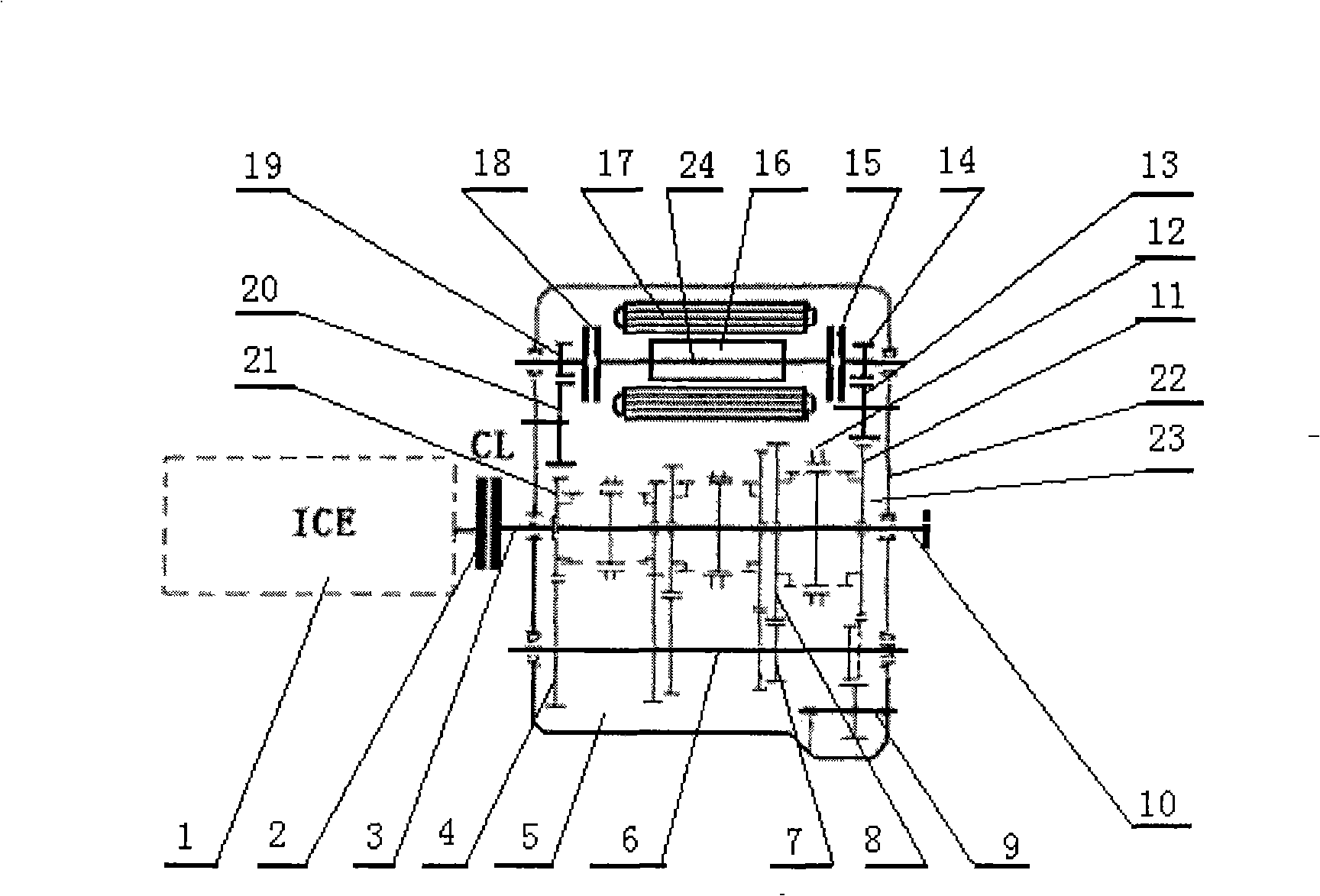

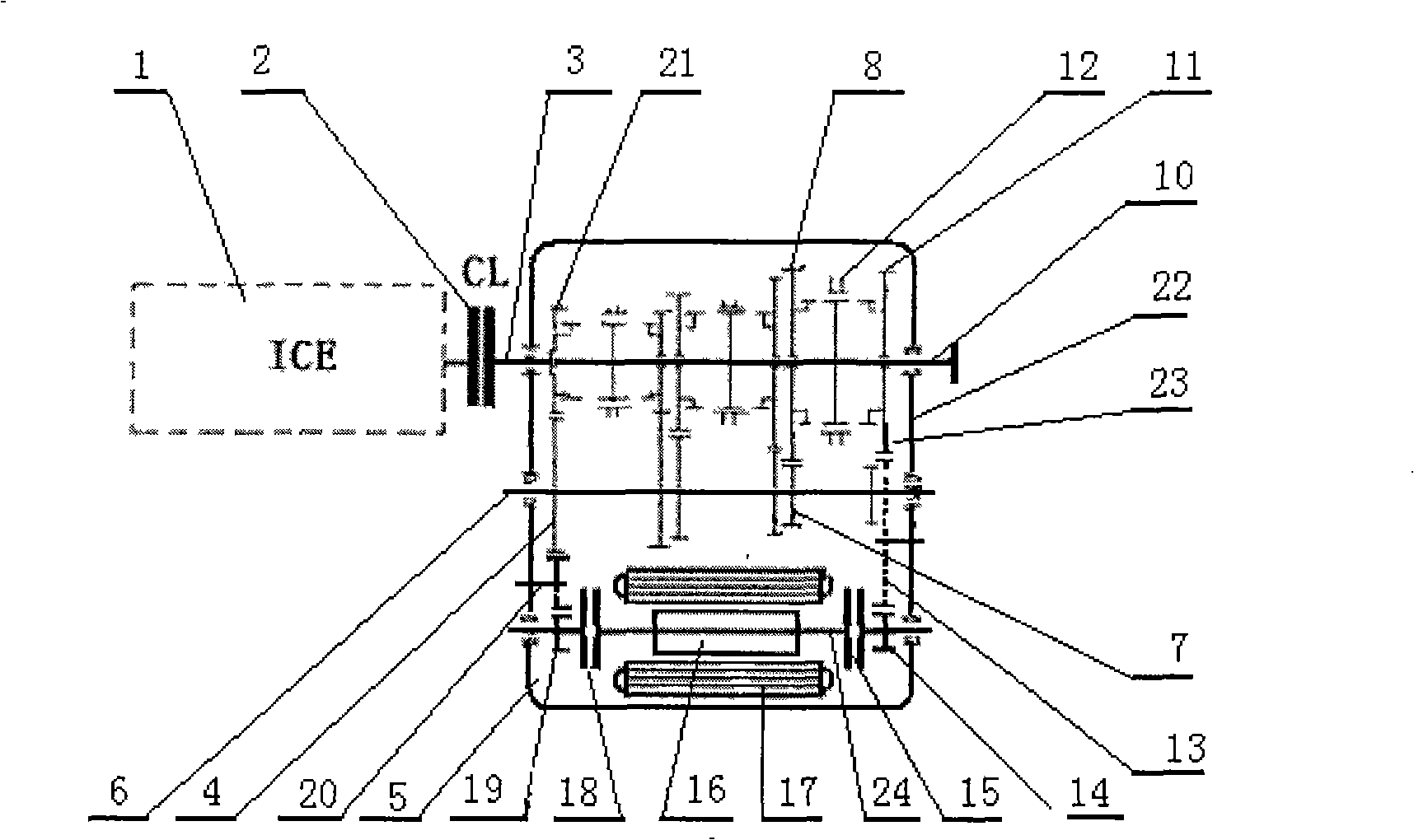

[0009] Such as figure 1 As shown, an engine 1 (not included in the present invention) is connected with an input shaft 3 on a gearbox 5 through a clutch 2 . The gearbox 5 includes a gearbox case 22, and the input shaft 3, the output shaft 10, the intermediate shaft 6 and the reverse gear shaft 9 are arranged in the case body 22, and the speed change gear transmission between the input shaft, the output shaft, the intermediate shaft and the reverse gear shaft Department 23. The speed change gear drive train 23 is similar to the speed change gear drive train in the conventional gearbox, and will not be repeated here.

[0010] A generator / motor stator 17 and a rotor 16 are arranged inside the gearbox case 22 , and the rotor shaft is a bidirectional output shaft 24 . Both ends of the bidirectional output shaft 24 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com