Mobile phone, mobile phone panel and manufacturing method thereof

A manufacturing method and panel technology, applied in the direction of telephone structure and other directions, can solve the problems of prolonged product production time, low molding yield rate and high machine cost, and achieve the effects of saving processes, improving yield rate and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

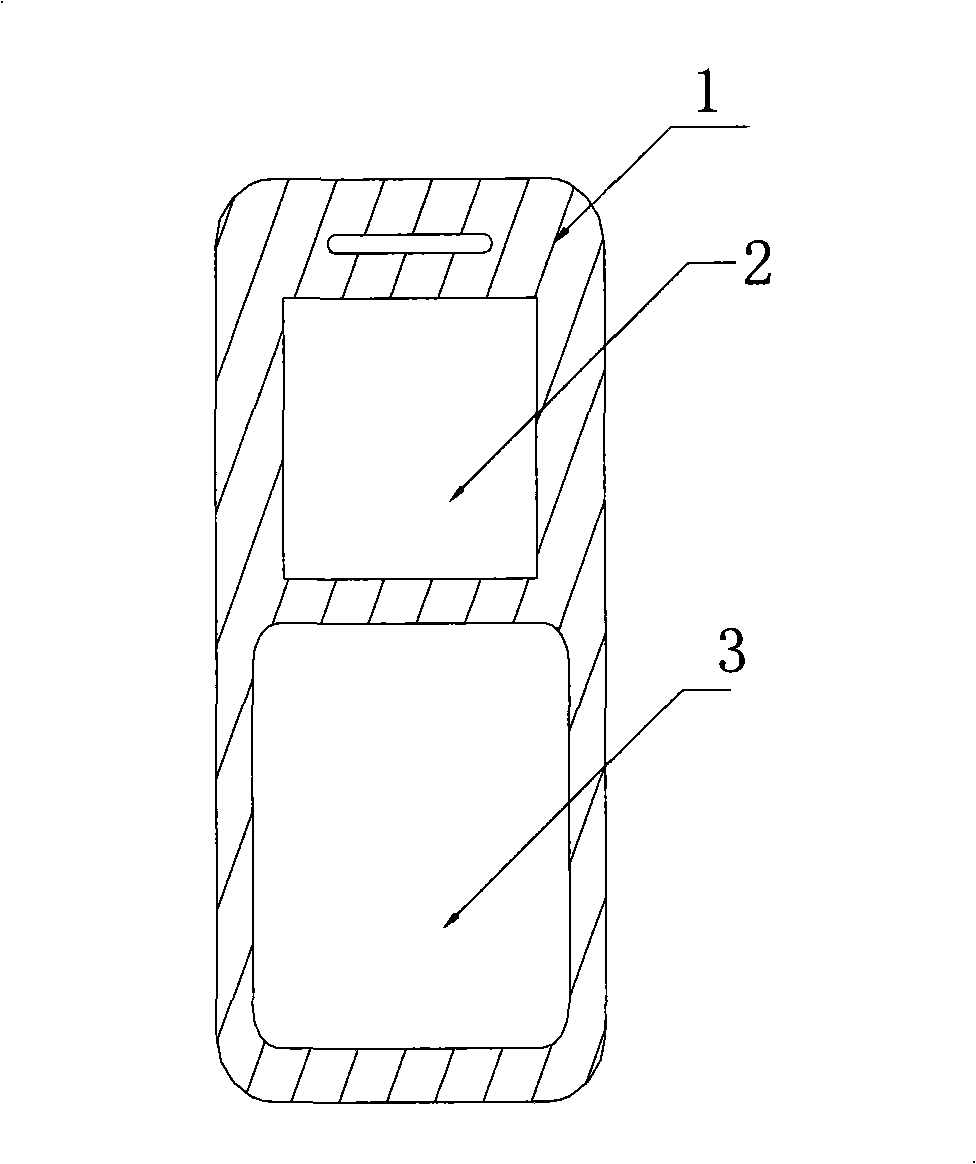

[0035] The basic structure and principle of the mobile phone in this embodiment are the same as those of the prior art, including panels, keyboards, display screens, and main circuit boards. In this way, the shell area and the window area of the panel sheet are integrally formed, and the pattern color layer covers the shell area of the panel sheet.

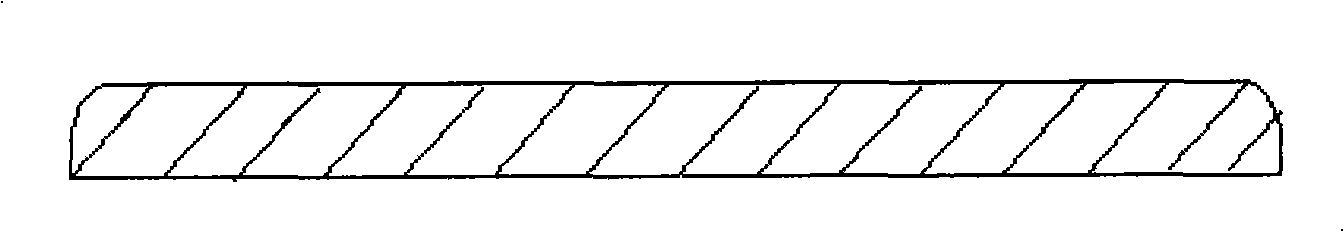

[0036] Such as figure 1 , figure 2 as shown, figure 1 It is a schematic cross-sectional view of the mobile phone panel in this embodiment, which adopts a single-layer single-material structure.

[0037] The manufacturing of the mobile phone panel in this example adopts the method of one-time molding of the panel sheet, and the panel sheet used can be APET (heat-shrinkable polyester), PETG (ethylene glycol modified-polyethylene terephthalate) ), PC, PS (polystyrene) and other materials. The panel sheet material is required to have excellent optical properties and stretchability, and the thickness of the panel sheet is abou...

Embodiment 2

[0054] The difference from the first embodiment is that the mobile phone panel of this embodiment has a keypad support.

[0055] The molded mobile phone panel, in addition to the outer casing part 10 and the window part 20, also includes a keypad bracket 31 for realizing key installation. Such as Figure 5 As shown, at the time of printing, except for the window portion 20, the keypad 30 of the panel sheet is also left blank. Such as Figure 6 As shown, after the panel sheet is formed by hot pressing, a part of the material of the keypad 30 is punched out using a corresponding punching die, so as to punch out the keypad bracket 31 .

[0056] It can be seen from the above specific implementation manners that the mobile phone panel manufacturing method of the present invention is simple and practical, and its molding process is conducive to the improvement of the yield rate, and can effectively save the cost of raw materials, molds and machine tools.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com