Organic polymer electronic memory manufacturing method

A polymer and memory technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, circuits, etc., to achieve good solubility and film-forming properties, good stability, and simplified preparation and implementation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

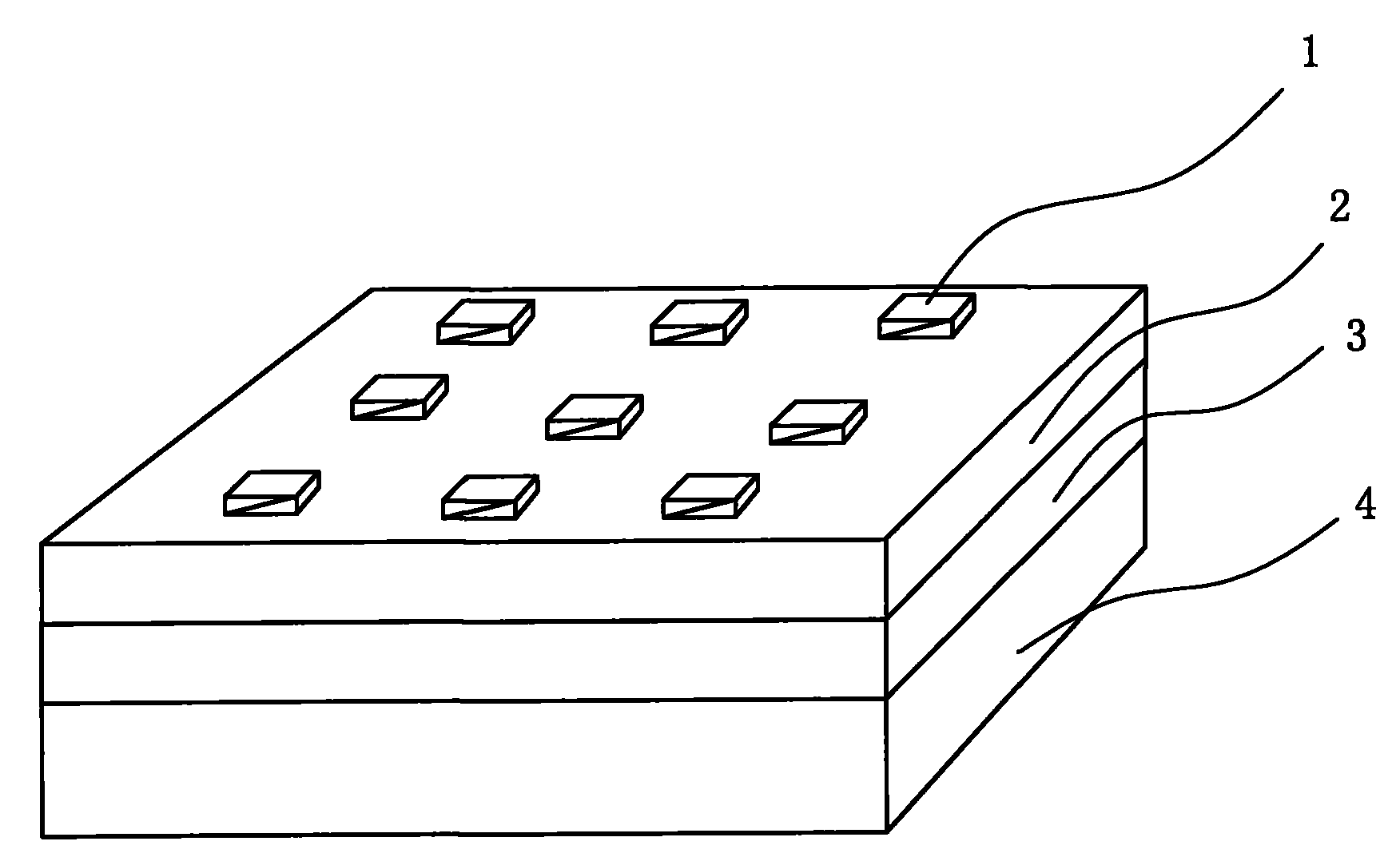

[0041] First, the cut ITO glass sheet is ultrasonically washed with water for 15-30 minutes, and then ultrasonically washed with acetone and isopropanol 3 times, each time for 15-20 minutes. Remove the glass pieces and blow dry and set aside.

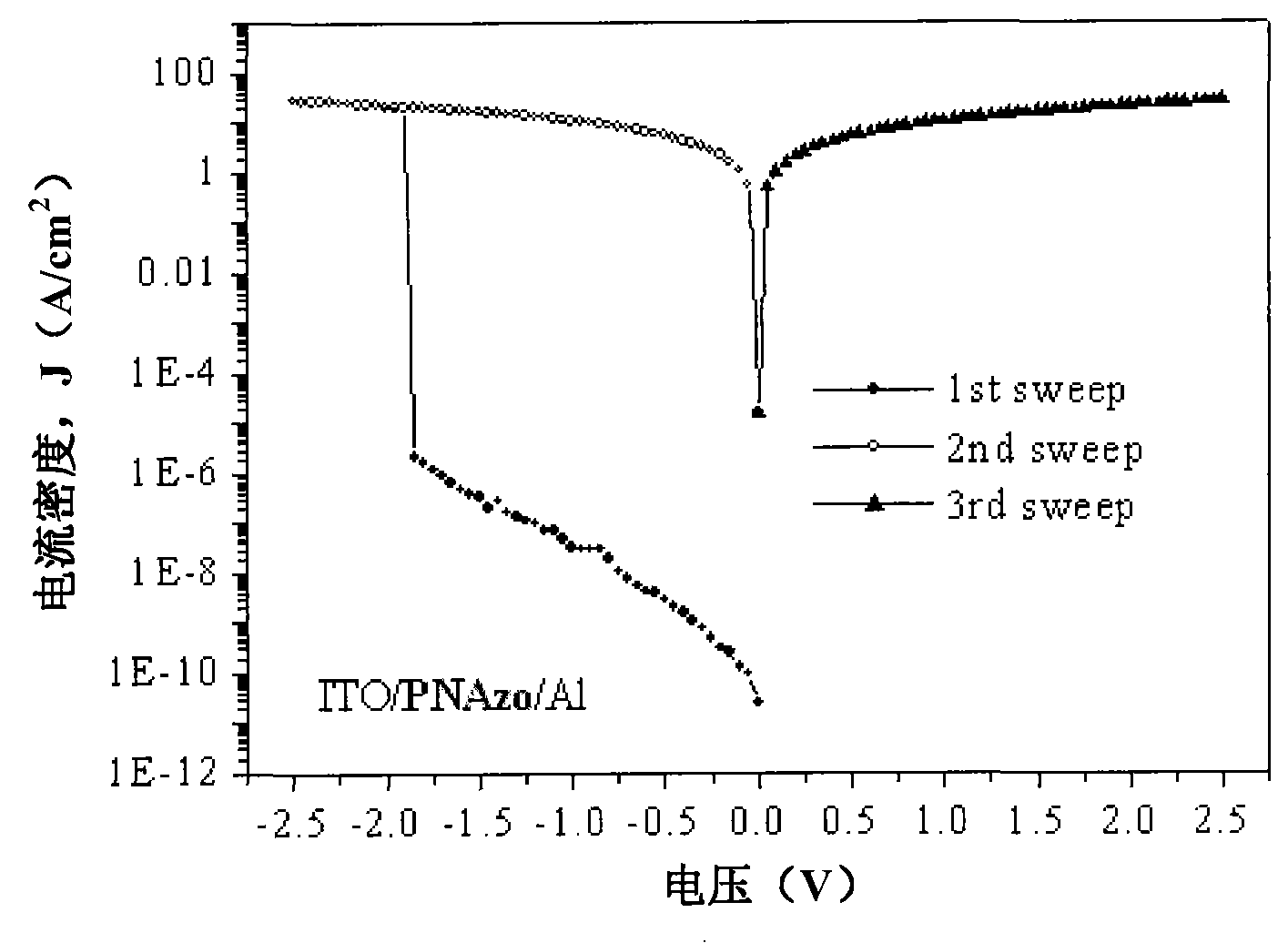

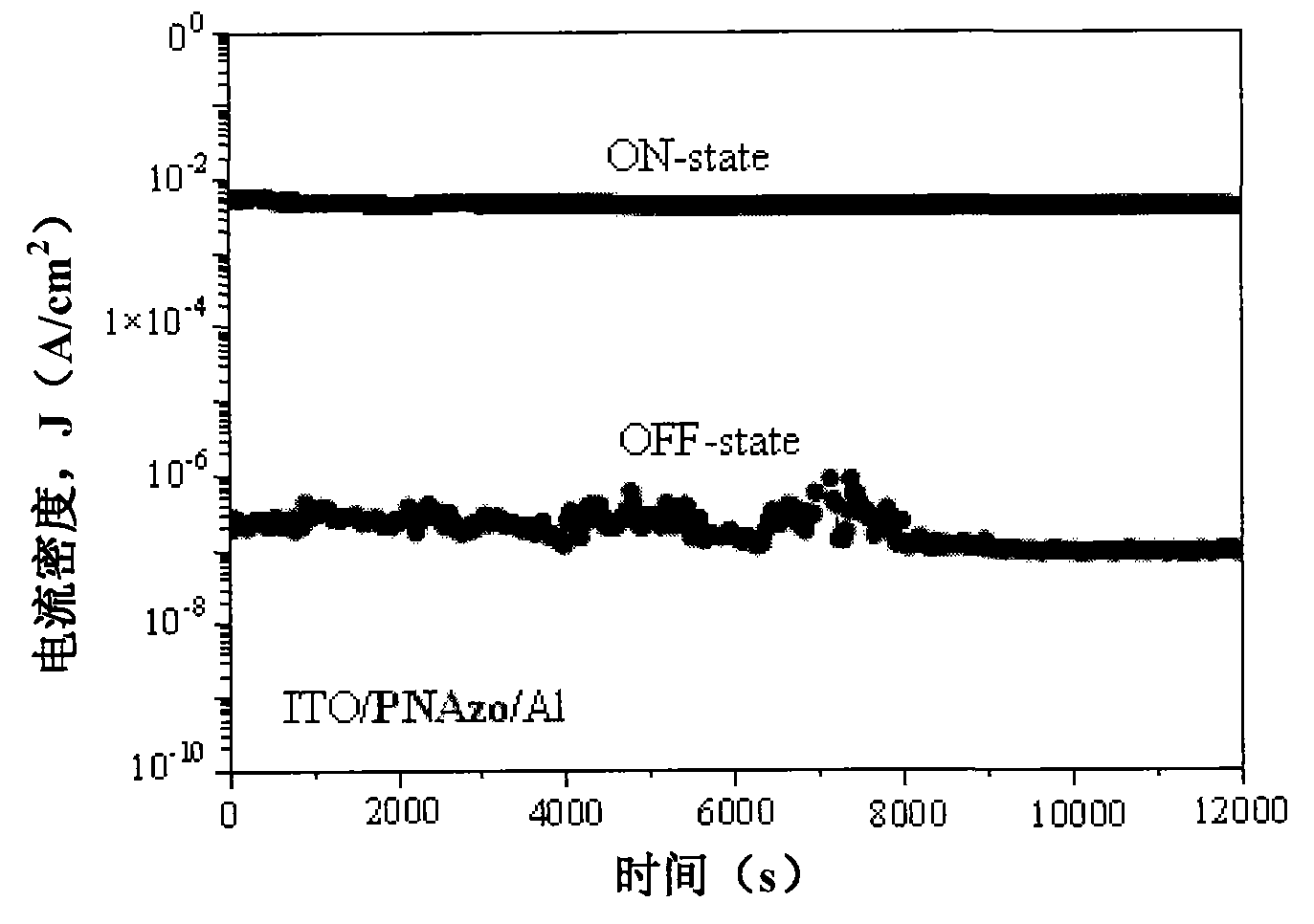

[0042] The azo polymer (PNAzo) with an average molecular weight of 3800 and a nitro group at the end is formulated into a solution of N,N-dimethylacetamide at an amount of 10-15mg / ml, and spin-coated Azo polymer is coated on the surface of ITO glass (rotating speed is 1500-2000 rpm, 60 seconds), and placed in a vacuum oven (1×10 -5 torr, 60°C) and dried for 10 hours to obtain a uniform azo polymer film. The thickness of the polymer film is about 50 nm.

[0043] Finally, use a vacuum evaporation instrument to measure less than 1×10 -7 Under the vacuum of torr, high-purity Al with a thickness of about 150nm and an area of 0.4×0.4mm is vaporized as the upper electrode. The vapor deposition rate of the Al electrode is controlled at 1-3nm / s. ...

Embodiment 2

[0048] The cut ITO glass slide is ultrasonically washed with water for 15-30 minutes, and then ultrasonically washed with acetone and isopropanol 3 times for 15-20 minutes each time. Remove the glass piece and blow dry.

[0049] Azo polymer (PBAzo) with an average molecular weight of 4700 and a bromine group at the end substituent is prepared into a solution of N,N-dimethylacetamide at an amount of 10-15mg / ml, and spin-coated. Coat the azo polymer on the surface of the ITO glass (rotating speed is 1500-2000 rpm, 60 seconds), and place it in a vacuum oven (1×10 -5 torr, 60°C) and dried for 10 hours to obtain a uniform azo polymer film. The thickness of the polymer film is approximately 60 nm.

[0050] Finally, use a vacuum evaporation instrument to measure less than 1×10 -7 Under the vacuum of torr, high-purity Al with a thickness of about 180nm and an area of 0.4×0.4mm is vaporized. As the upper electrode, the vapor deposition rate of the Al electrode is controlled at 1-3nm / s, a...

Embodiment 3

[0053] The cut ITO glass slide is ultrasonically washed with water for 15-30 minutes, and then ultrasonically washed with acetone and isopropanol 3 times for 15-20 minutes each time. Remove the glass pieces and blow dry and set aside.

[0054] An azo polymer (PMAzo) with an average molecular weight of 5000 and a methoxy group as the terminal substituent is prepared into a solution of N,N-dimethylacetamide at an amount of 10-20mg / ml, and the solution is spin-coated Azo polymer is coated on the surface of ITO glass (rotating speed is 1500-2000 rpm, 60 seconds), and placed in a vacuum oven (1×10 -5 torr, 60°C) and dried for 10 hours to obtain a uniform azo polymer film. The thickness of the polymer film is about 80 nm.

[0055] Finally, use a vacuum evaporation instrument to measure less than 1×10 -7 Under the vacuum degree of torr, high-purity Al with a thickness of about 160nm and an area of 0.4×0.4mm is vaporized. As the upper electrode, the vapor deposition rate of the Al elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com