Organic polymer electronic memory and manufacturing method therefor

A polymer and memory technology, which is used in the manufacture of semiconductor/solid-state devices, electric solid-state devices, circuits, etc., to achieve the effects of good solubility and film-forming properties, good stability, and simplified preparation and implementation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

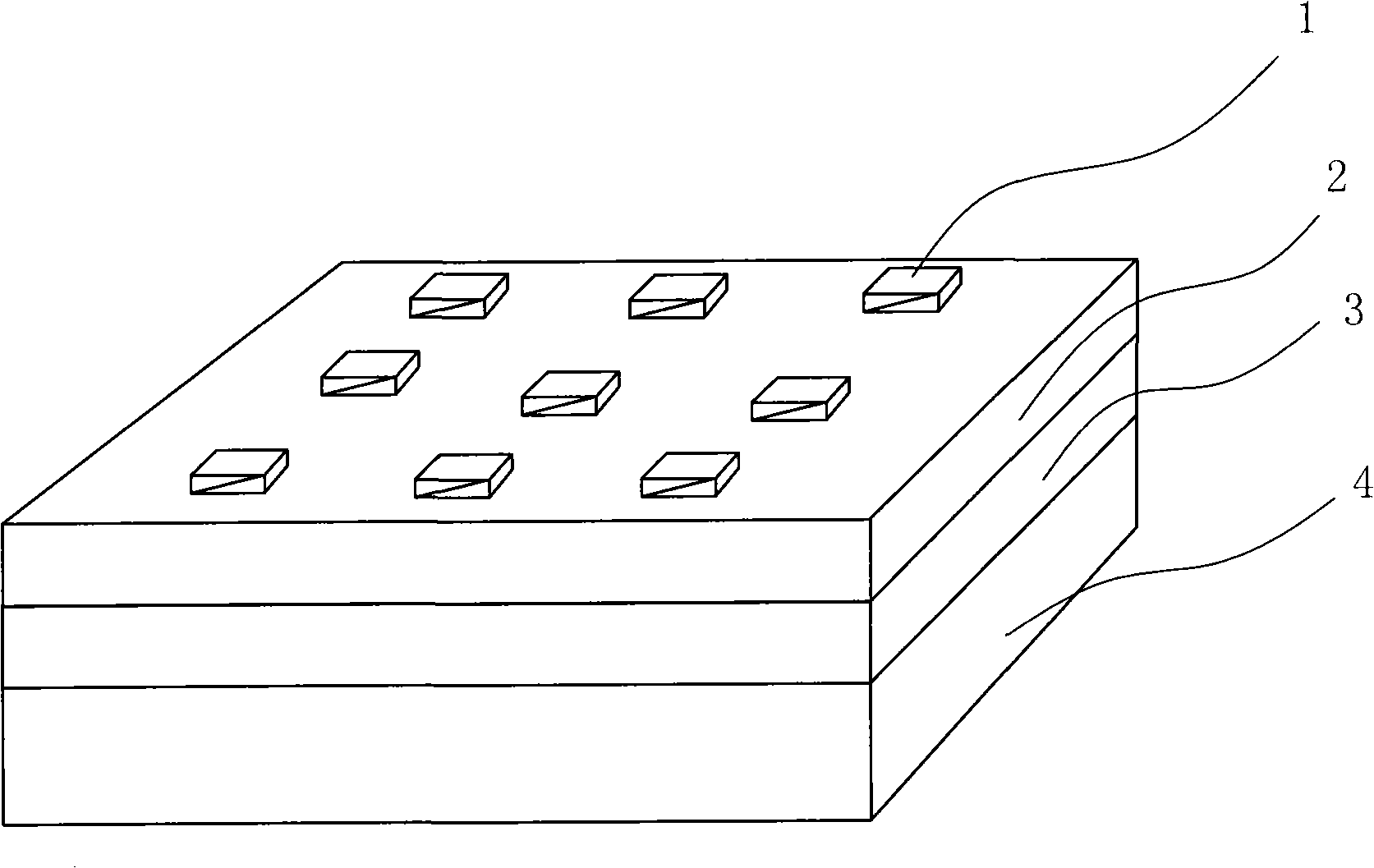

[0041] Firstly, the cut ITO glass sheet is ultrasonically washed with water for 15-30 minutes, and then ultrasonically washed with acetone and isopropanol for 3 times, each time for 15-20 minutes. Remove the glass slices and blow dry for later use.

[0042] The average molecular weight is 3800, and the azo polymer (PNAzo) whose terminal substituent is nitro is formulated into a solution of N, N-dimethylacetamide in an amount of 10-15 mg / ml, and the The azo polymer is coated on the surface of ITO glass (1500-2000 rpm, 60 seconds), and placed in a vacuum oven (1×10 -5torr, 60°C) for 10 hours to obtain a uniform azo polymer film. The thickness of the polymer film is about 50 nm.

[0043] Finally, use a vacuum evaporator at less than 1×10 -7 Under the vacuum degree of torr, high-purity Al with a thickness of about 150 nm and an area of 0.4×0.4 mm is evaporated as the upper electrode. The evaporation rate of the Al electrode is controlled at 1-3nm / s.

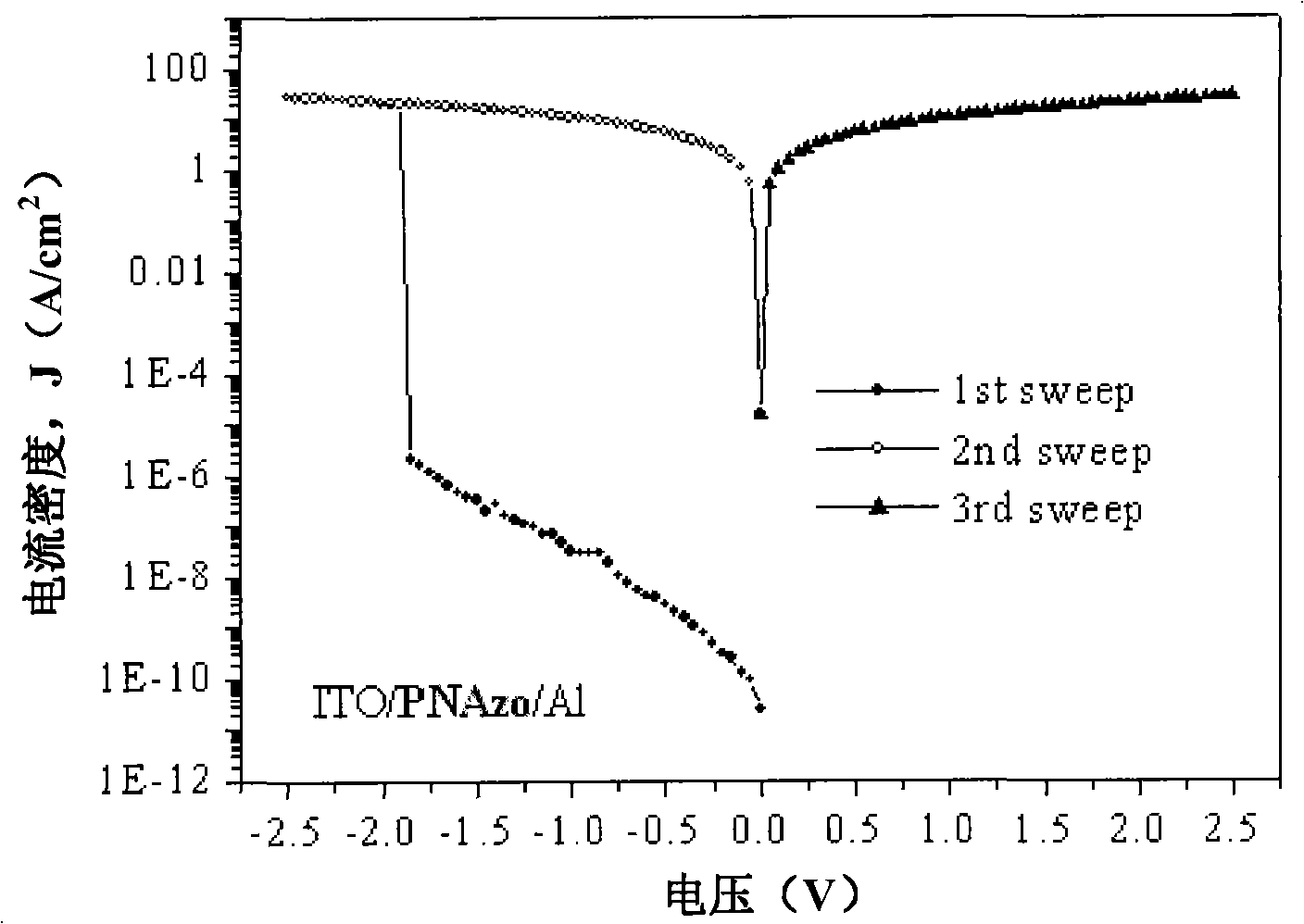

[0044] attached figur...

Embodiment 2

[0048] The cut ITO glass slides were ultrasonically washed with water for 15-30 minutes, and then ultrasonically washed with acetone and isopropanol for 3 times, each time for 15-20 minutes. Remove the glass piece and blow dry.

[0049] The average molecular weight is 4700, and the azo polymer (PBAzo) whose terminal substituent is a bromine group is formulated into a solution of N,N-dimethylacetamide in an amount of 10-15mg / ml, and the method of spin coating Apply the azo polymer on the surface of ITO glass (1500-2000 rpm, 60 seconds), put it in a vacuum oven (1×10 -5 torr, 60°C) for 10 hours to obtain a uniform azo polymer film. The thickness of the polymer film is about 60nm.

[0050] Finally, use a vacuum evaporator at less than 1×10 -7 Under the vacuum degree of torr, high-purity Al with a thickness of about 180nm and an area of 0.4×0.4mm is evaporated. As the upper electrode, the evaporation rate of the Al electrode is controlled at 1-3nm / s, and the structure is as f...

Embodiment 3

[0053] The cut ITO glass slides were ultrasonically washed with water for 15-30 minutes, and then ultrasonically washed with acetone and isopropanol for 3 times, each time for 15-20 minutes. Remove the glass slices and blow dry for later use.

[0054] The average molecular weight is 5000, and the azo polymer (PMAzo) whose terminal substituent is methoxy is formulated into a solution of N, N-dimethylacetamide in an amount of 10-20 mg / ml, and the The azo polymer is coated on the surface of ITO glass (1500-2000 rpm, 60 seconds), and placed in a vacuum oven (1×10 -5 torr, 60°C) for 10 hours to obtain a uniform azo polymer film. The thickness of the polymer film is about 80nm.

[0055] Finally, use a vacuum evaporator at less than 1×10 -7 Under the vacuum degree of torr, high-purity Al with a thickness of about 160nm and an area of 0.4×0.4mm is evaporated. As the upper electrode, the evaporation rate of the Al electrode is controlled at 1-3nm / s, and the structure is as attache...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com