Steel-smelting continuous casting production scheduling method for taking molten steel residency time limit into account

A residence time, steelmaking and continuous casting technology, applied in the information field, can solve the problems of unfavorable enterprises' cost reduction and efficiency increase goals, long residence time of molten steel, and affecting the stability of the production system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0101] Specific embodiments of the present invention will be described below in combination with technical solutions and accompanying drawings.

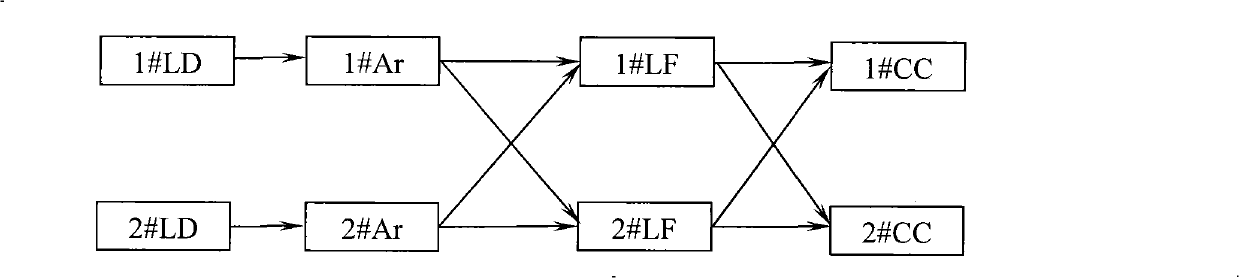

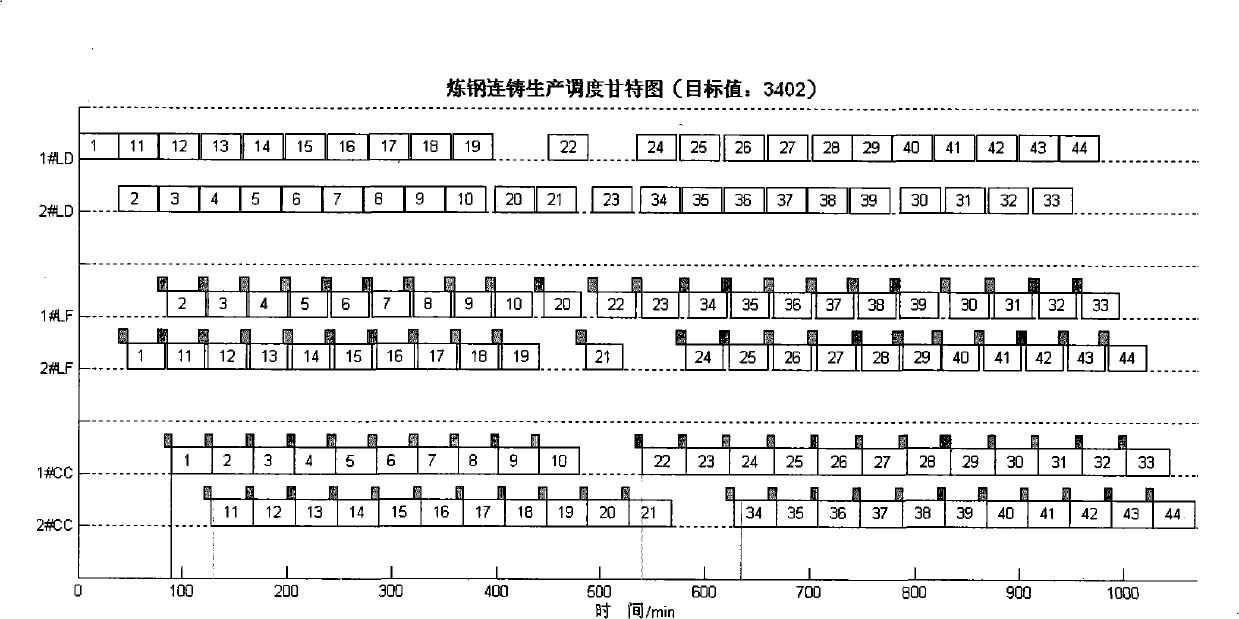

[0102] Taking the actual production data of a large converter steel plant as an example, its production process is as follows figure 2 shown. In this example, the argon blowing process time is incorporated into the LD to LF transport time. For the four pouring times, the data of 10, 11, 12, and 11 heats are respectively included in the calculation. The parameters of the genetic algorithm are as follows: the population size is 40, the two offspring with the best fitness values are reserved, the crossover probability is 0.8, and the algorithm end criterion is 100 generations of continuous iterations or no improvement in 10 consecutive generations. Running on a notebook with CPU T5600 (1.83G) and RAM 2G, the average calculation time is 55.6 seconds, which shows that the calculation efficiency of the algorithm can meet the requireme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com