Stainless steel wrap wire for sodium cooled fast reactor core assembly and method for preparing same

A technology of stainless steel and wire winding, applied in the field of alloys, can solve the problem of inability to meet the radial positioning and winding of fast reactor element rods, and achieve excellent wire surface quality, ensure dimensional tolerance, and ensure the effect of dissolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

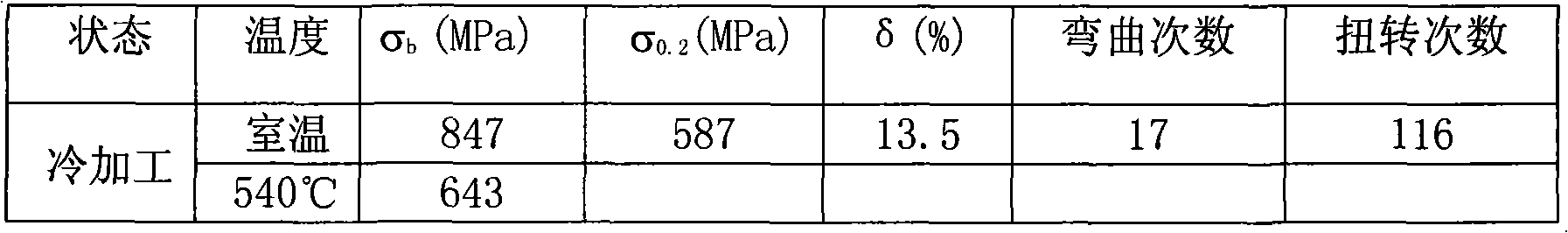

Examples

Embodiment 1

[0037] Use the technical scheme provided by the present invention to prepare the φ0.6mm winding wire used for positioning the element rod in the stainless steel reflector assembly of the sodium-cooled fast reactor, with a weight of 2kg.

[0038] Concrete preparation steps are as follows:

[0039] (1) According to the following composition and weight ratio, and use vacuum induction melting furnace and consumable electrode vacuum electric arc furnace to smelt molten steel respectively: 0.04% to 0.08% of C; ≤0.75% of Si; ≤0.02% of P ;≤0.02% S; 1.5%~2.0% Mn; 11.0%~14.0% Ni; 16.0%~18.0% Cr; 2.0%~3.0% Mo; 0.3%~0.5% Ti;≤0.1% ≤0.002% of B; ≤0.035% of N; the rest is Fe. During the smelting process, pure metals are used for ingredients, and the addition of rare earth elements is prohibited. After smelting, use a rod and wire rod rolling machine to open the billet to make a stainless steel plate billet.

[0040] (2) Thermal processing. At each stage of cold working, the selected heat...

Embodiment 2

[0047] Proportioning is with embodiment 1. The difference is that during smelting, the first time is smelting in argon-oxygen furnace, and the second time is electroslag remelting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com