Reagent kit for preparing chemical mechanical polishing aqueous dispersion, and use thereof

一种化学机械、分散体的技术,应用在化学机械研磨,化学机械研磨用水系分散体领域

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

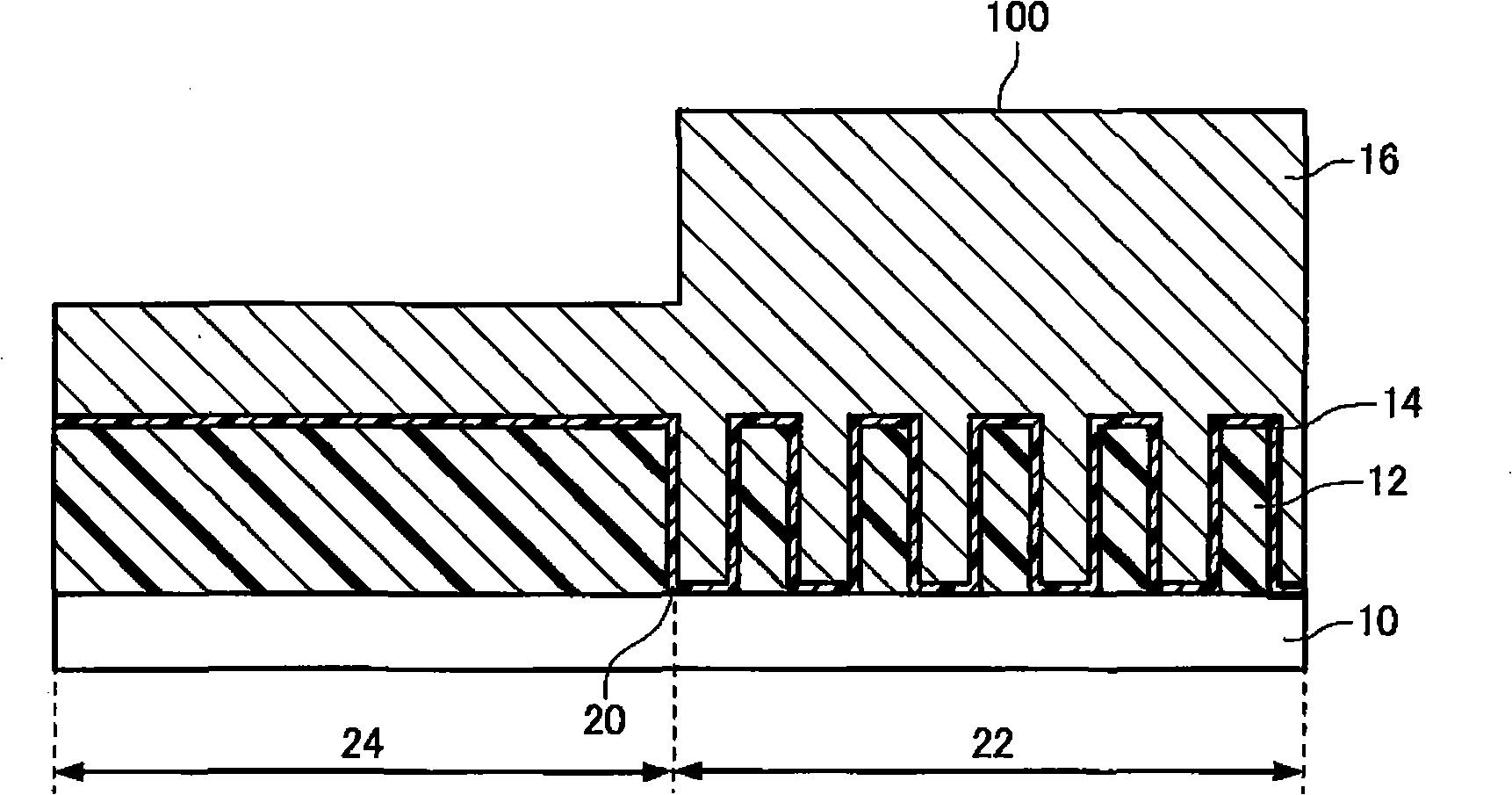

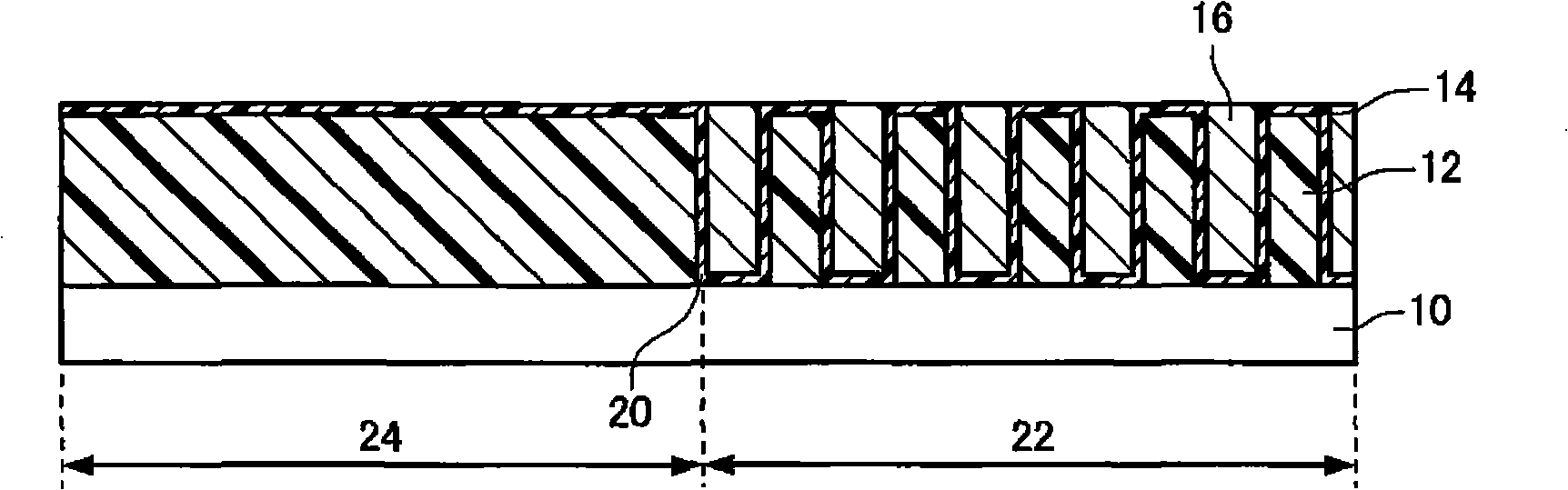

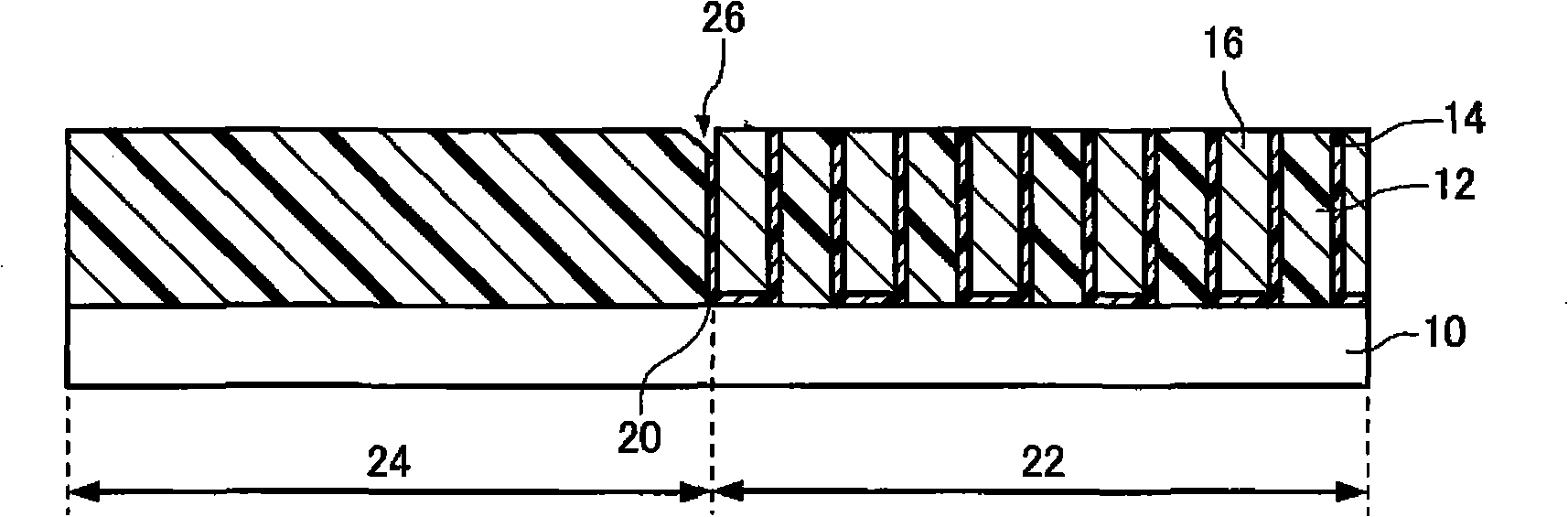

Image

Examples

preparation example Construction

[0111] 4.2 Preparation method of chemical mechanical grinding aqueous dispersion

[0112] The chemical mechanical polishing aqueous dispersion preparation kit of this embodiment can be prepared by mixing the first composition and the second composition constituting the kit, and further mixing with the third composition containing an oxidizing agent as needed. Mechanical milling of aqueous dispersions. As this mixing method, the following aspects can be employed.

[0113] (1) The first composition, the second composition, and the third composition containing an oxidizing agent may be mixed in advance to prepare a chemical mechanical polishing aqueous dispersion, and the chemical mechanical polishing aqueous dispersion may be prepared from a slurry The supply nozzle 32 supplies the above-mentioned flow rate onto the turntable 40 .

[0114] (2) Any one of the first composition or the second composition may be mixed with the third composition containing an oxidizing agent, each ...

Embodiment 2

[0202] (a) Preparation of the first composition

[0203] Ion-exchanged water was added to the colloidal silica C2-containing aqueous dispersion prepared in the above "5.1.1" so that the content of the colloidal silica C2-containing aqueous dispersion was equivalent to 18.5% by mass in terms of inorganic particles The amount, and then add potassium hydroxide to adjust the pH to 10.0. Then, ion-exchanged water was added so that the total amount of all constituents became 100% by mass, followed by filtration with a filter having a pore diameter of 1 μm to obtain an aqueous dispersion (C) containing 18.5% by mass of colloidal silica. In addition, this aqueous dispersion (C) was uniformly dispersed, and the average particle diameter of the colloidal silica in the aqueous dispersion (C) was 45 nm.

[0204] (b) Preparation of the second composition

[0205] 0.2% by mass of quinolinic acid and 0.8% by mass of benzotriazole were dissolved in ion-exchanged water, and polyacrylic acid ...

Embodiment 3

[0217] (a) Preparation of the first composition

[0218] Add the aqueous dispersion containing colloidal silica C1 prepared in "5.1.1" above, the aqueous dispersion containing colloidal silica C3 prepared in "5.1.1" above, and ion-exchanged water to make the The content of the aqueous dispersion containing colloidal silica C1 was equivalent to 0.8% by mass in terms of inorganic particles, and the content of the aqueous dispersion containing colloidal silica C3 was equivalent to 10.0% by mass in terms of inorganic particles, and then added Potassium hydroxide adjusted the pH to 10.3. Then, ion-exchanged water was added so that the total amount of all constituents became 100% by mass, followed by filtration with a filter having a pore diameter of 1 μm to obtain an aqueous dispersion (E) containing 10.8% by mass of colloidal silica. In addition, this aqueous dispersion (E) was uniformly dispersed, and the average particle diameter of the colloidal silica in the aqueous dispersio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com