Intelligent control system for vehicle mounted type intelligent steel rail-coating device

A technology of intelligent control system and coating device, which is applied to the device for coating liquid on the surface, electrical program control, program control in sequence/logic controller, etc. , affecting the coating efficiency and convenience of operation, etc., to achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Curved rail dry lubrication coating is to heat the solid lubricant to make the lubricant melt into a liquid state, and then spray it on the inner surface of the curved rail through the gear pump and the feeding pipeline, and form a solid lubricating film after rolling by the wheel, which plays a role Reduce the wear of curved rails.

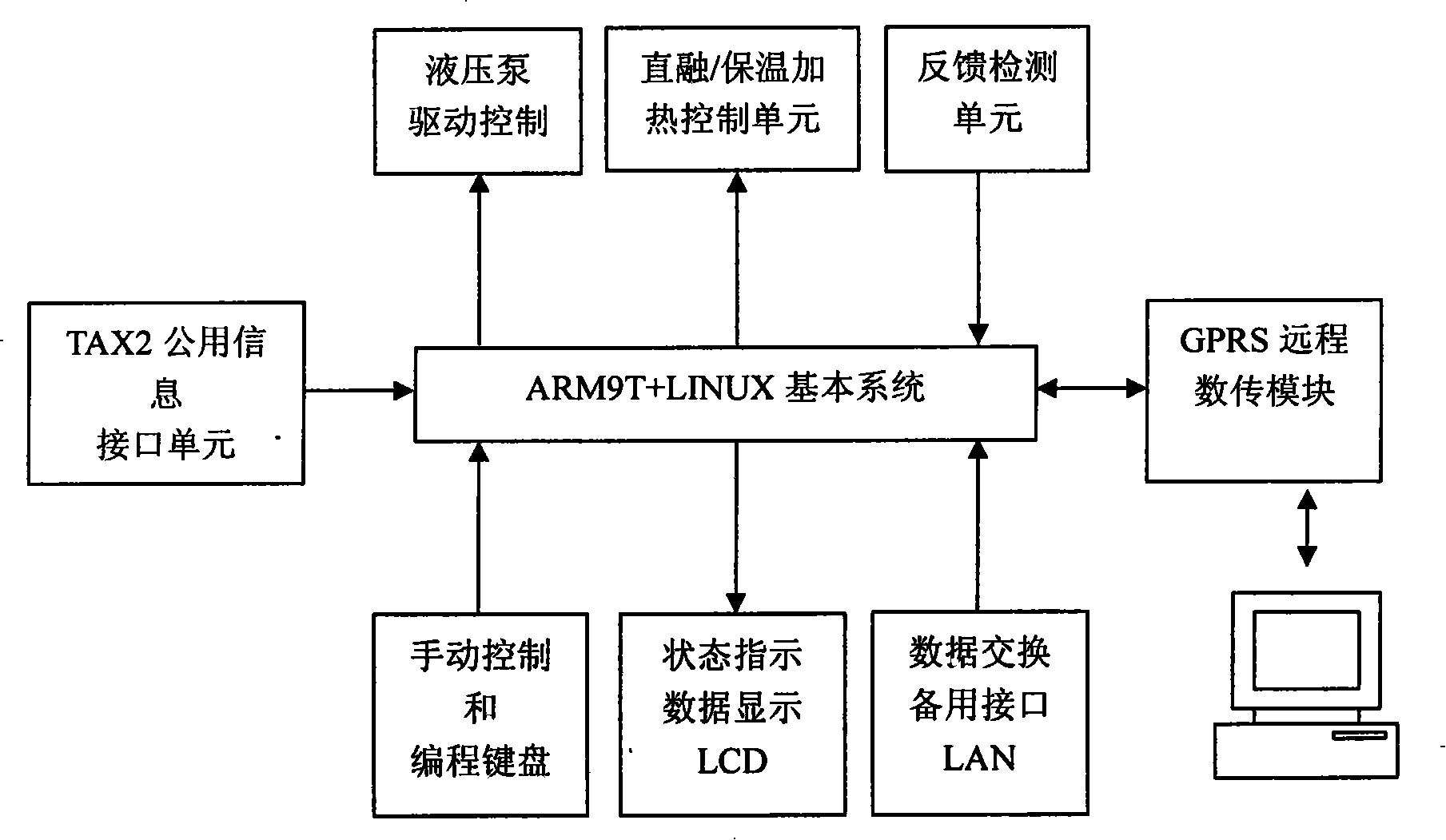

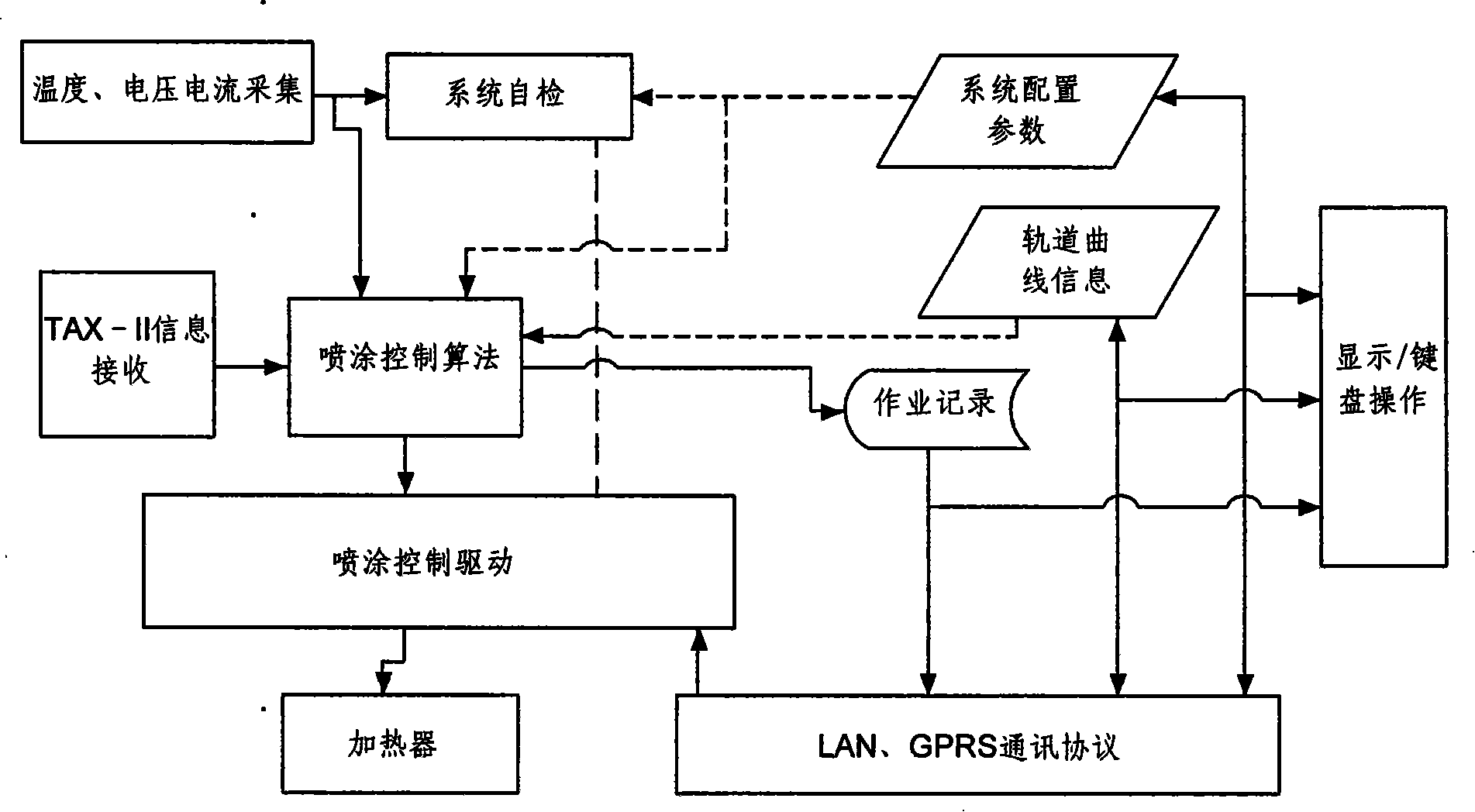

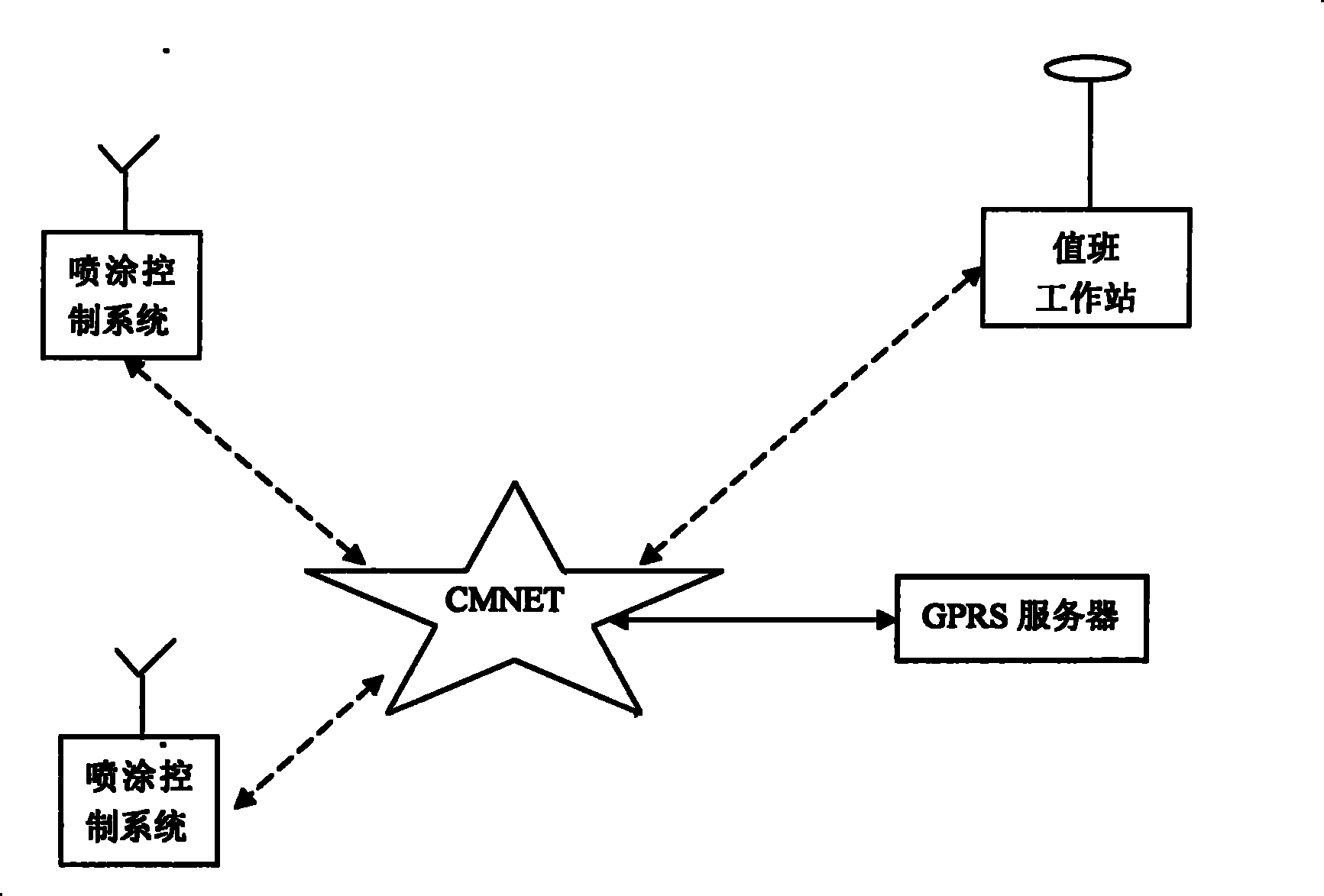

[0034] In order to realize the automatic identification of curves during the operation of the vehicle-mounted intelligent rail coating device, the automatic control of the coating operation, the unattended spraying process, and the automation and intelligence of the entire operation process, this requires a set of vehicle-mounted intelligent rail coating Device intelligent control system. It mainly includes spraying intelligent control system and temperature control system. Under the function of the control system, the device can realize the automation and intelligent control of the whole operation process.

[0035] 1. Functions of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com