Three-dimensional measurement method of laser welding temperature field

A technology of laser welding and three-dimensional measurement, applied in the field of measurement, can solve problems such as difficulty in obtaining accurate data and unsatisfactory results for limited thick parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

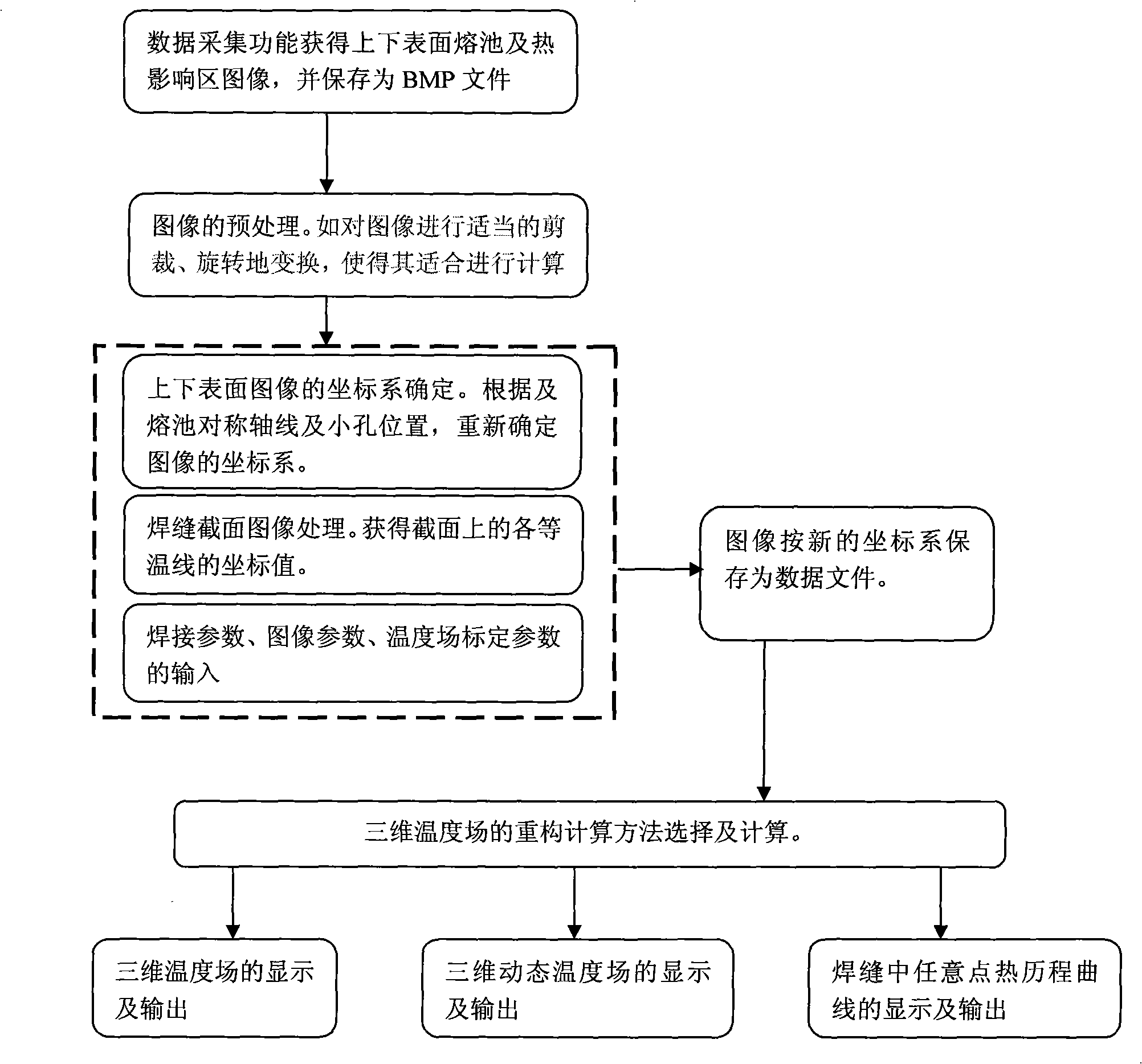

[0018] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

[0019] The three-dimensional measurement method of the laser welding temperature field, the steps are:

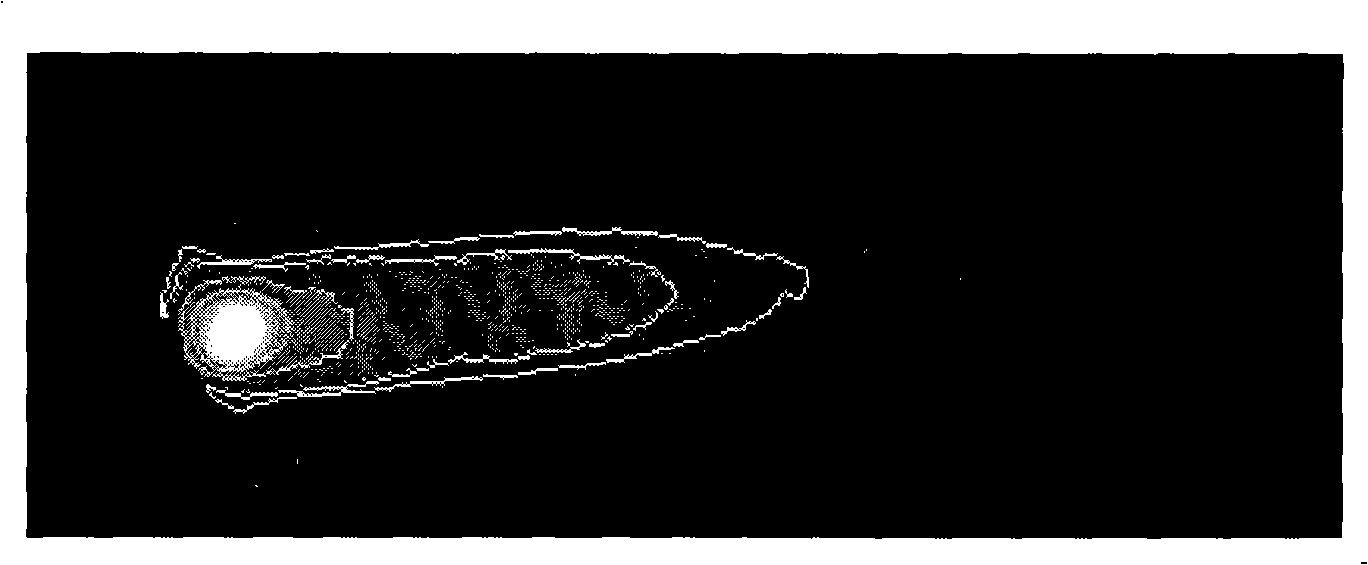

[0020] (1) Using the image sensing system to obtain the grayscale image of the melting area and its heat-affected area during laser welding;

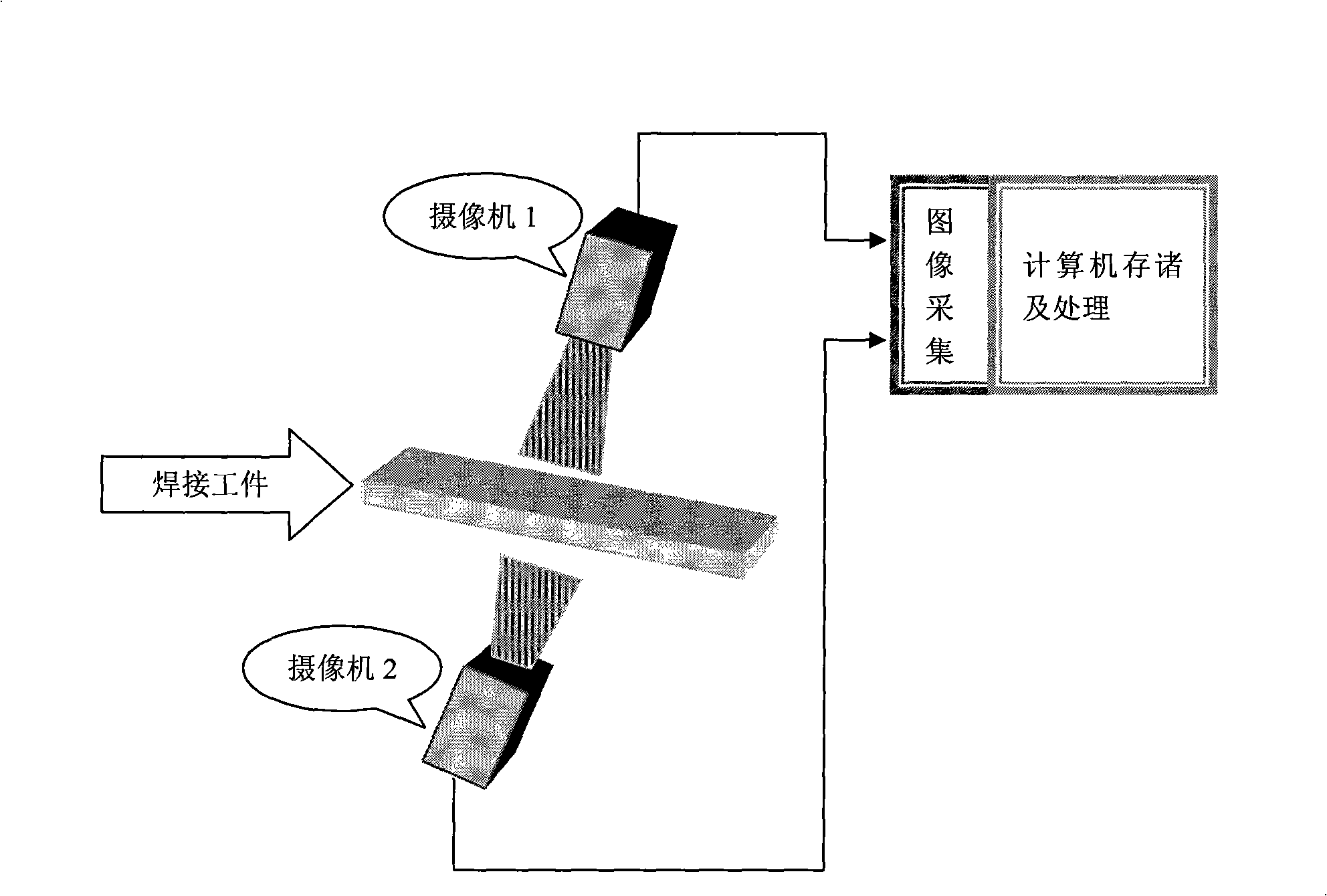

[0021] The composition of the measurement system adopts a dual optical path system, such as figure 1 As shown, two sets of CCD image sensors are used to simultaneously measure the front and back melt pool images. This scheme can ensure the consistency of the measured temperature field over time, and can obtain the real measurement value of the temperature field at a certain moment. The system uses a high-pixel CCD image sensor to ensure a high geometric resolution of the temperature field on the surface of the molten pool. According to the purpose of the analysis, different temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com