Extrusion type combined peeling machine and cornmill for Cycas revoluta

A technology of extrusion type and pulverizer, which is applied in the direction of bark, manufacturing tools, wood processing utensils, etc., to achieve the effect of high peeling rate, increased added value and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

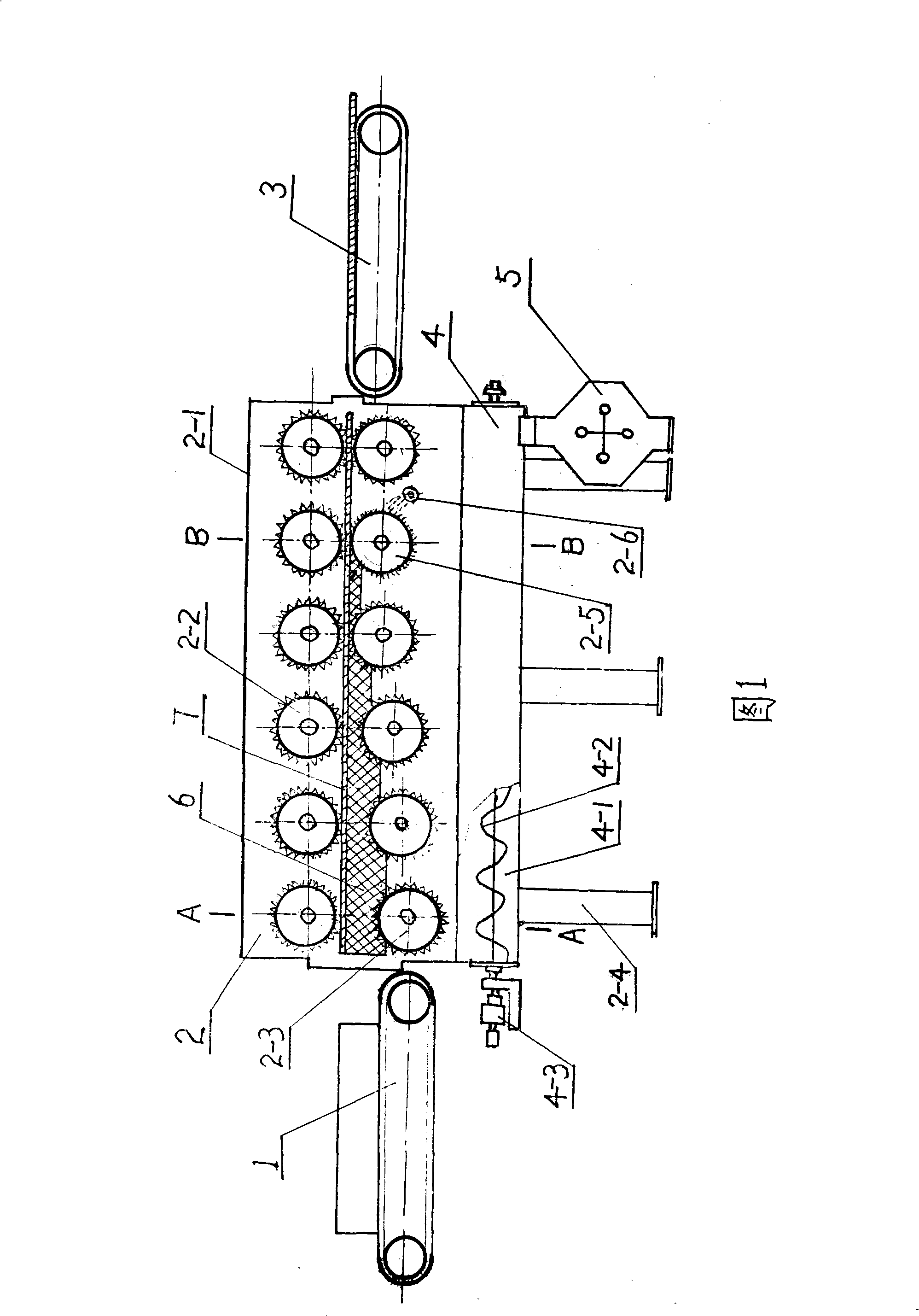

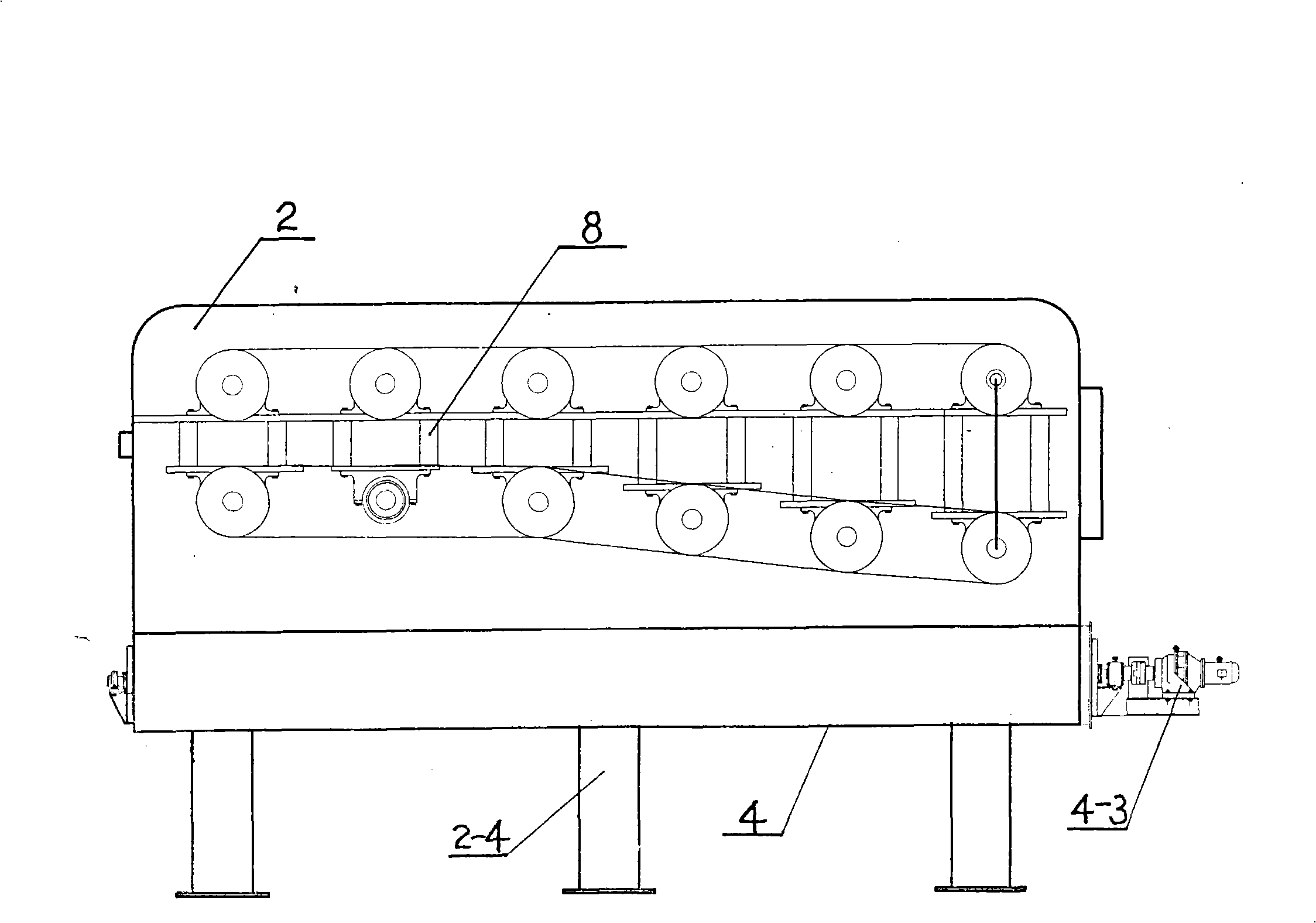

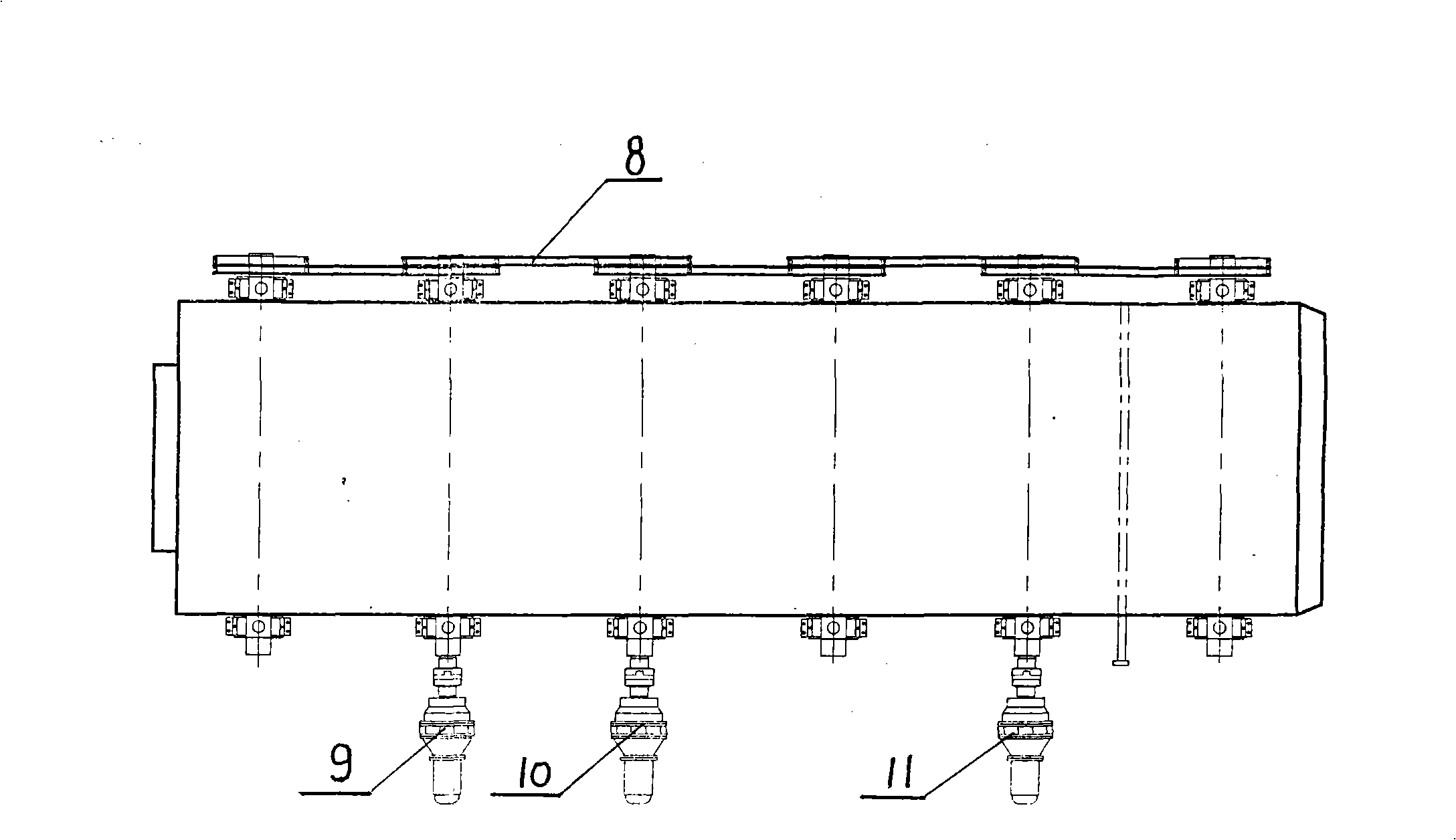

[0016] See Figure 1, figure 2 , image 3 , the extruding type sand tree combined peeling and milling machine of the present invention is made up of trunk conveyor 1, peeling pith extraction machine 2, bark conveyor 3, tree pith collecting and transporting mechanism 4 and pulverizer 5, and trunk conveyor 1 is located at the feeding end of the peeling and pitting machine 2, and the bark conveyor 3 is located at the bark outlet end of the peeling and pitting machine 2. The peeling and pitting machine 2 has a box body 2-1 installed on the frame body 2-4, and the upper and lower rows of rollers are respectively installed through the shaft seat in the box body 2-1, wherein the upper row is provided with at least 3 or more rollers. Nip roller 2-2, the lower row is provided with extrusion roller 2-3 and cleaning roller 2-5, and extrusion roller 2-3 and cleaning roller 2-5 correspond to nip roller 2-2 one by one , in pairs, the number of which can be increased or decreased according ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com