Method of producing printed circuit board incorporating resistance element

A technology for printed wiring boards and manufacturing methods, which can be used in the fields of printed circuit manufacturing, electrical components, multilayer circuit manufacturing, etc., and can solve problems such as inability to respond to resistance changes, difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

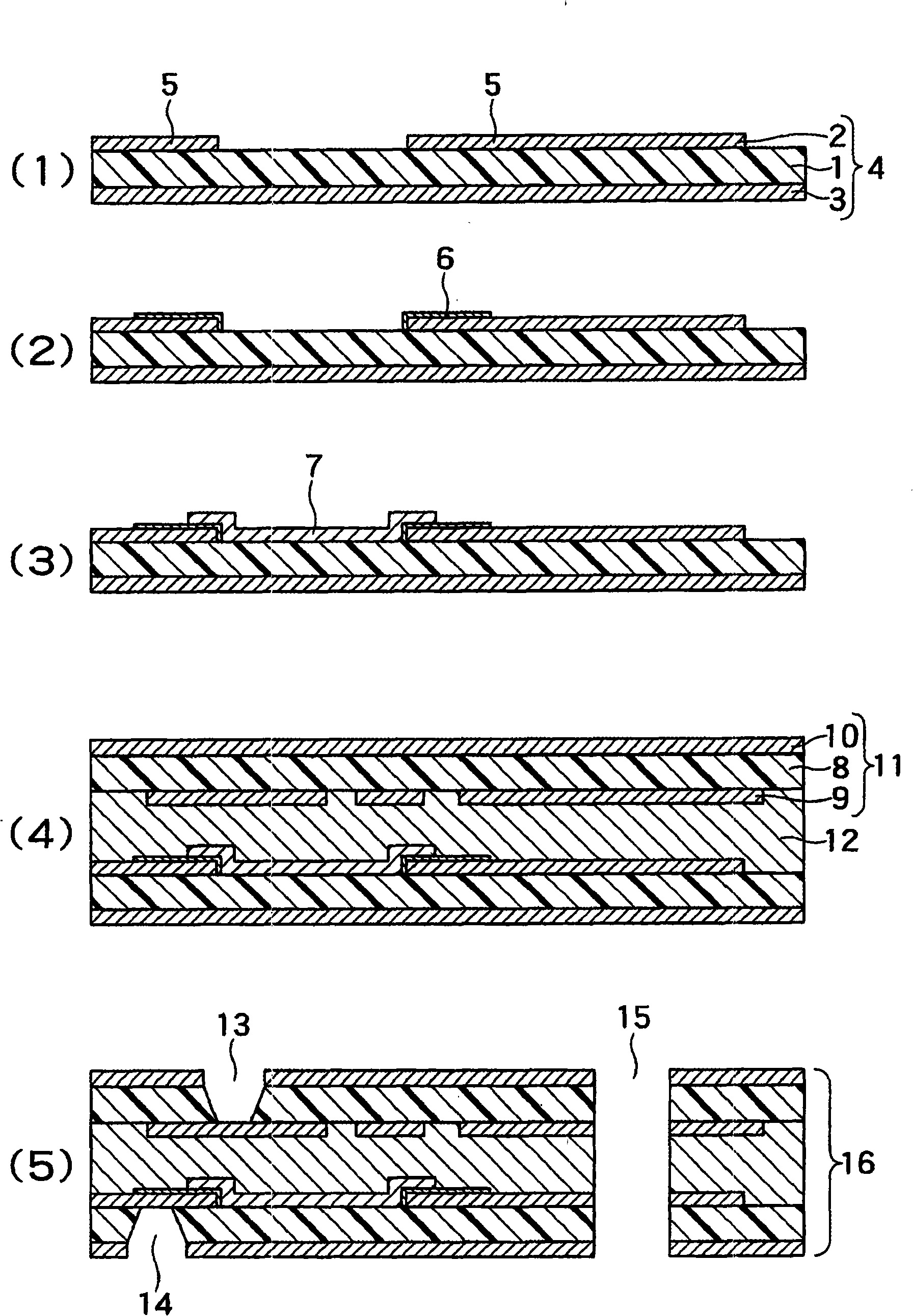

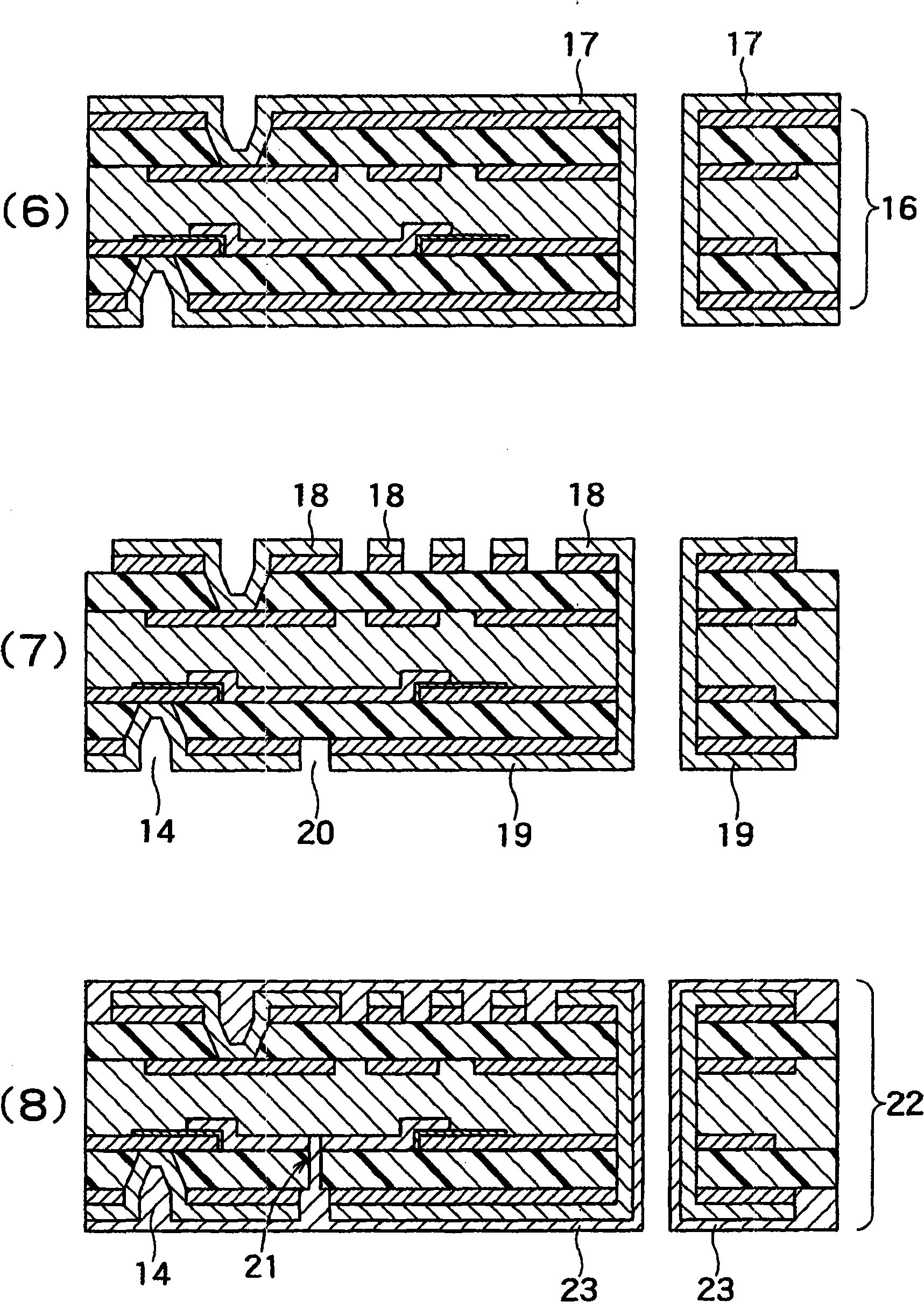

[0051] Figure 1A , Figure 1B It is a cross-sectional process view showing the manufacturing steps of the printed wiring board with built-in resistor element according to one embodiment of the present invention. First, if Figure 1A As shown in (1), a so-called double-sided copper-clad laminate 4 having a first metal foil 2 such as copper foil and a second metal foil 3 on both sides of an insulating base material 1 such as polyimide is prepared. Then, at a desired position of the first metal foil 2, a circuit is formed at the same time as the electrode 5 of the resistive paste is formed using an etching method by a usual photoprocessing method.

[0052]In addition, 25 μm thick polyimide was used as the base material, and 12 μm electrolytic copper foil was used as the metal foil. The resistance value is determined by the width and film thickness of the resistance paste, the distance between electrodes, and the sheet resistance value of the paste, and here, the distance betwee...

Embodiment 2

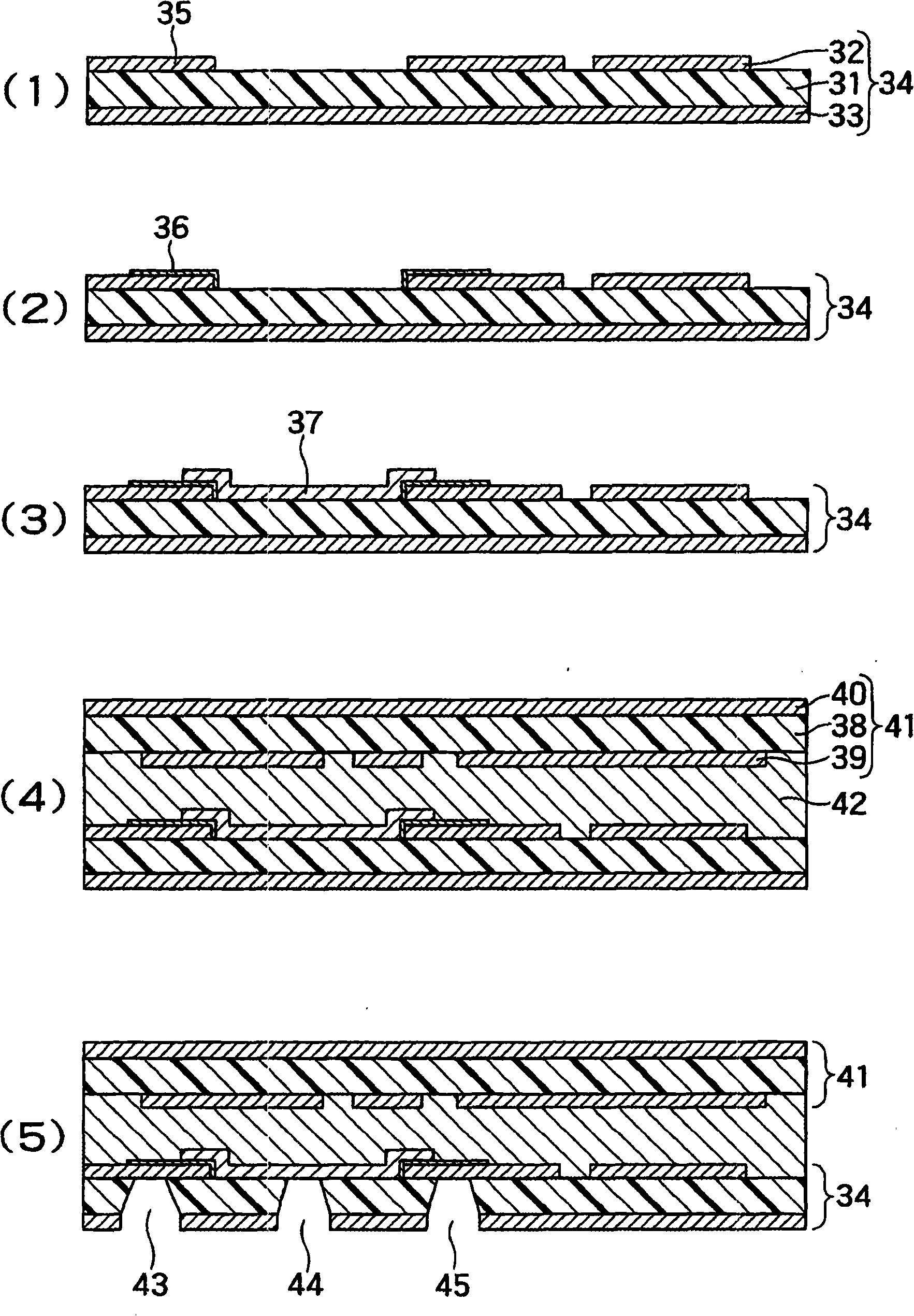

[0067] Figure 2A , Figure 2B It is a cross-sectional step diagram showing a method of manufacturing a printed wiring board with a built-in resistance element in one embodiment of the present invention. First, as Figure 2A As shown in (1), a so-called double-sided copper-clad laminate 34 having a first metal foil 32 such as copper foil and a second metal foil 33 on both sides of an insulating base material 31 such as polyimide is prepared. Desired positions of the foil 32 are etched using a common photoprocessing method, and a circuit is formed simultaneously with the electrodes 35 of the resistor paste.

[0068] In addition, 25 μm thick polyimide was used as the base material, and 12 μm electrolytic copper foil was used as the metal foil. The resistance value is determined by the width and film thickness of the resistance paste, the distance between electrodes, and the sheet resistance value of the paste, and here, the distance between electrodes is set to 1.0 mm.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com