Thermoelectric thin film structure

A thermoelectric thin film and thermoelectric technology, which is applied in the direction of thermoelectric device node lead wire materials, thermoelectric device components, etc., can solve the problems of low electrical conductivity and thermal conductivity, ZT value can not be effectively improved, and achieve the effect of simplifying the structure and composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

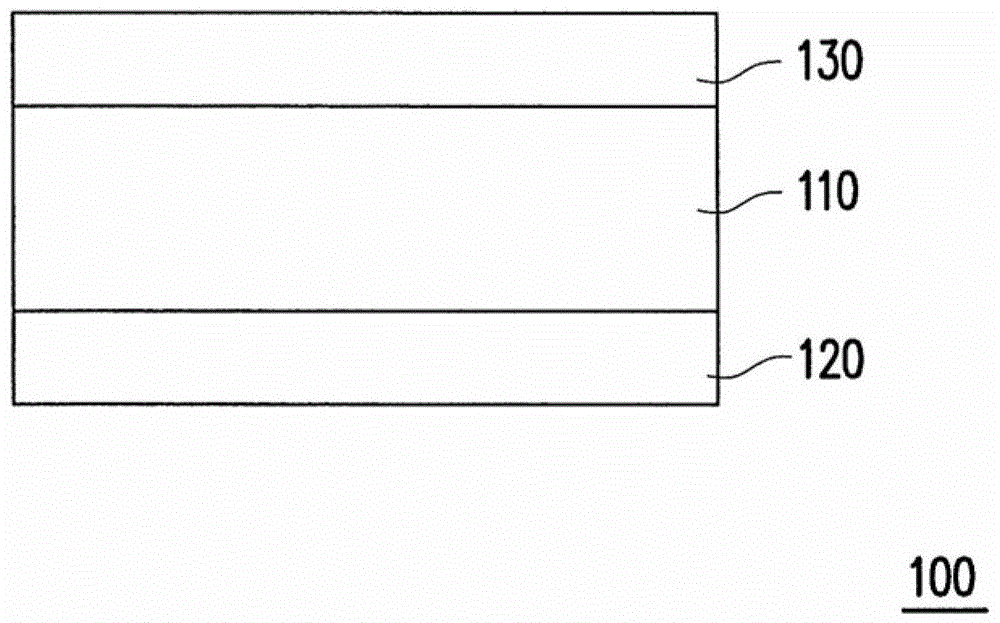

[0026] figure 1 is a schematic diagram of a thermoelectric thin film structure according to an embodiment of the present invention. Please refer to figure 1 , in this embodiment, the thermoelectric thin film structure 100 includes a thermoelectric substrate 110 and a pair of first diamond-like carbon layers 120, 130, wherein the first diamond-like carbon layers 120, 130 are disposed on opposite surfaces of the thermoelectric substrate 110 .

[0027] Here, the thermoelectric substrate 110 includes a material capable of converting heat into electricity, which can be a P-type thermoelectric material or an N-type thermoelectric material. For example, BiSbTe, BiSeTe, CsBi4Te6, Bi 2 Te 3 、 Bi 2 Te 3 / Se 2 Te 3 Superlattice, PbTeSeTe / PbTe quantum dots or superlattice, Zn 4 Sb 3 Alloy, Ce(Fe,Co) 4 Sb 12 , PbTe alloy, CoSb 3 , SiGe alloy, AgSbTe 2 / GeTe, Bi 2 Sr 2 co 2 o y , Ca 3 co 4 o 9 , Mg 2 Si, Na x CoO 2 , La 2 Te 3 , MnSi1.75, SnTe, TAGS (tellurium, ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com