Charging and discharging circuit for electrical system

A charge-discharge circuit and electrical system technology, applied in the field of machinery and electricity, can solve the problems of limited installation space, unfavorable heat dissipation of current-limiting circuits, and the inability to install large-power consumption energy release devices, etc., to achieve improved charge-discharge efficiency and strong mobility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

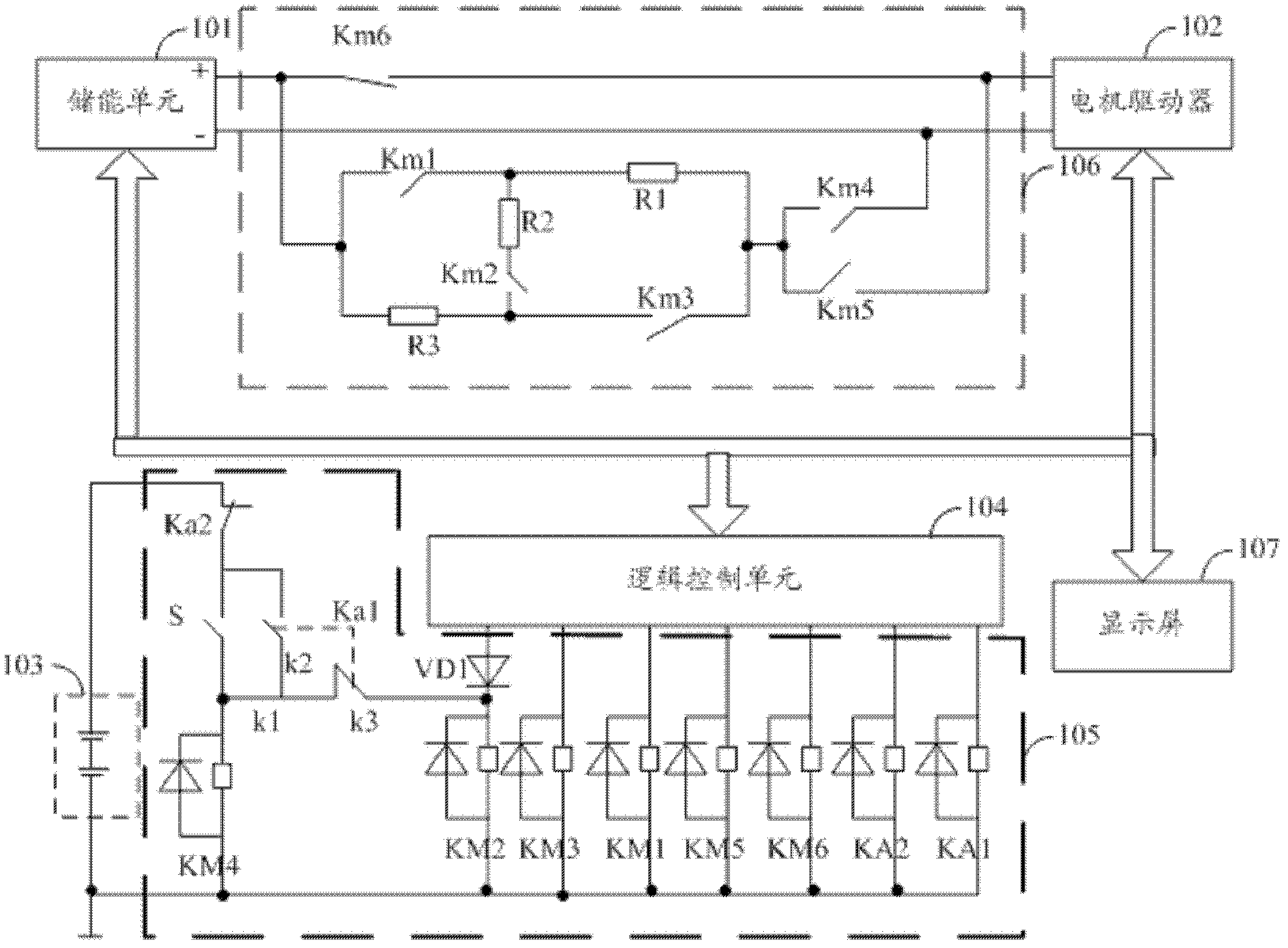

[0015] The main realization principles, specific implementation modes and corresponding beneficial effects of the technical solutions of the embodiments of the present invention will be described in detail below in conjunction with each accompanying drawing.

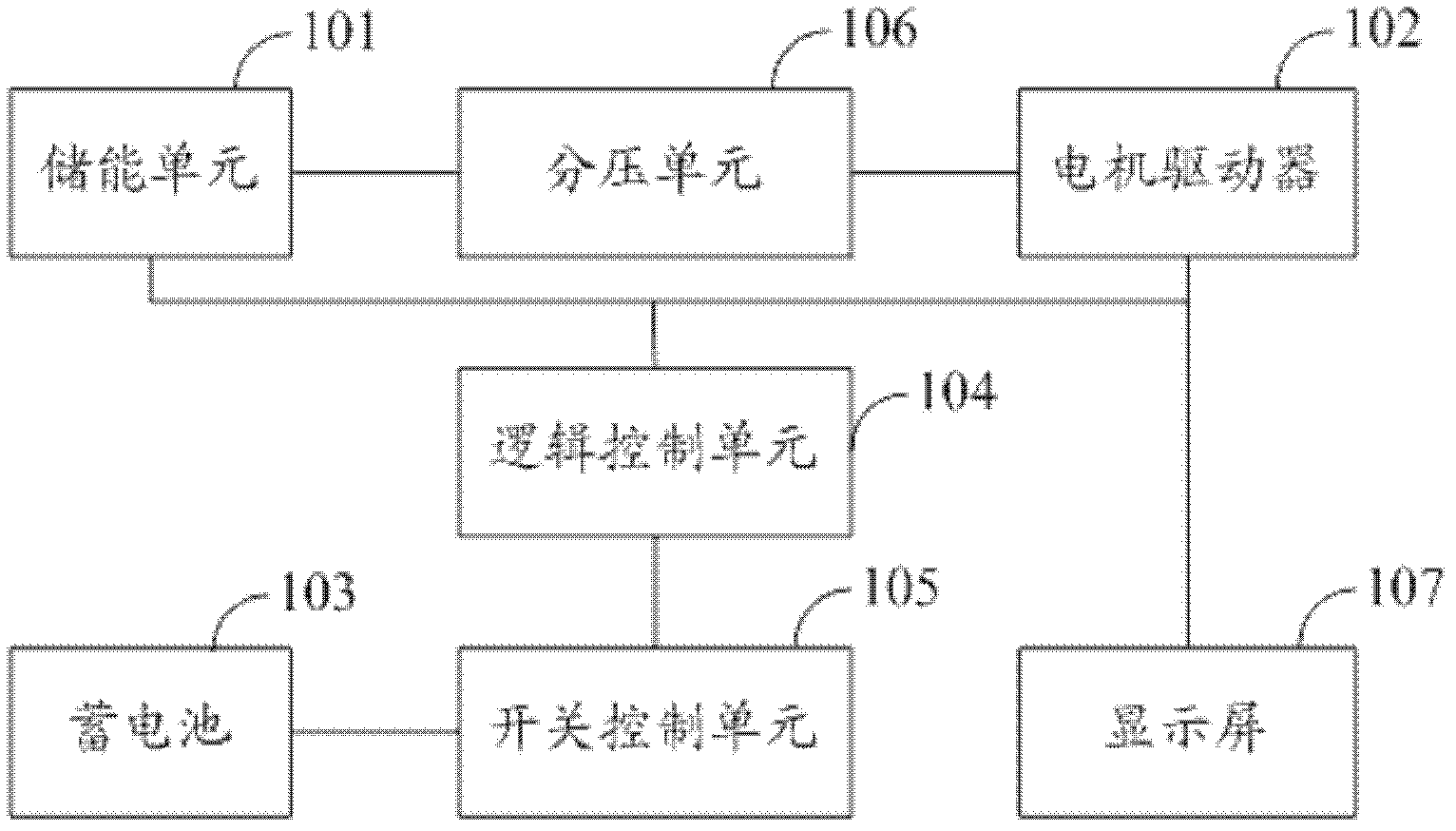

[0016] In order to solve the problems existing in the prior art, an embodiment of the present invention provides a charging and discharging circuit of an electrical system, such as figure 1 As shown, it includes: an energy storage unit 101, a motor driver 102, a storage battery 103, and also includes:

[0017] A logic control unit 104 is connected to the energy storage unit 101 and the motor driver 102 through a data bus;

[0018] The switch control unit 105 is connected with the logic control unit 104 and the storage battery 103, receives the logic control signal sent by the logic control unit 104, and controls the opening and closing of each touch point located in the voltage dividing unit 106;

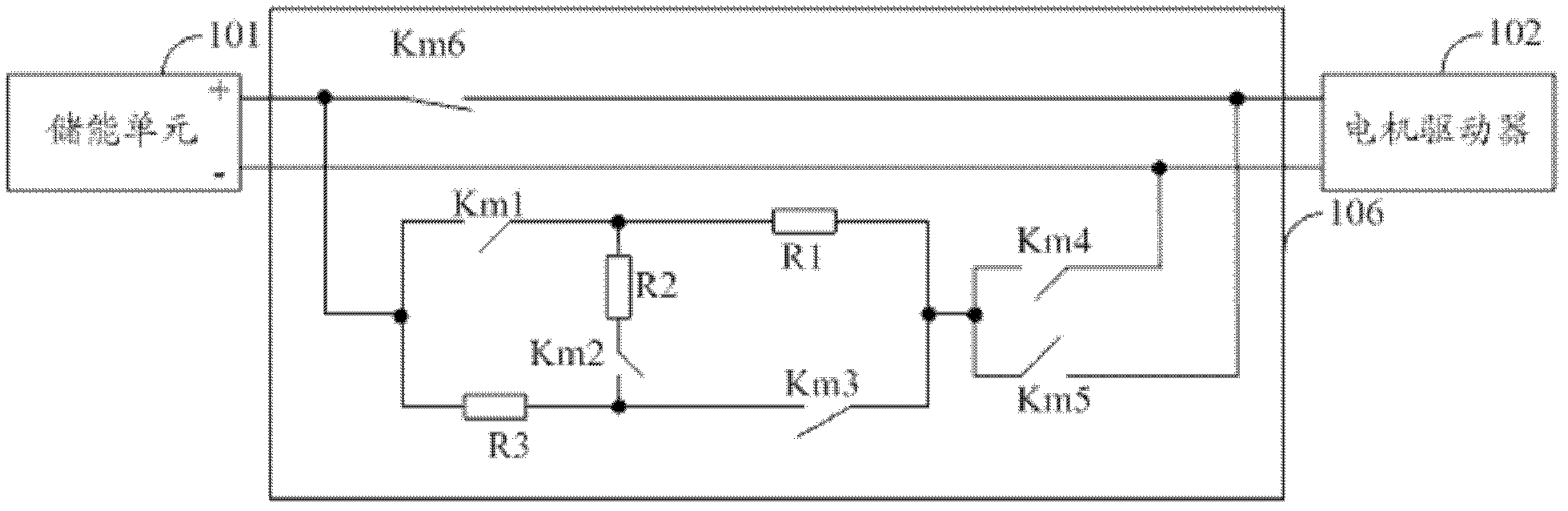

[0019] The voltage di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com