Tin-dioxide-base composite nano air-sensitive material and preparation method thereof

A technology of tin dioxide and gas-sensitive materials, applied in tin oxide, analytical materials, electrochemical variables of materials, etc., can solve the problem of high resistance value, achieve the effect of increasing the sensitivity K value, improving the microstructure, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0017] Weigh 1 part of tin dioxide-based nanorod grain powder and 0.5 part of tin dioxide-based nano-spherical grain powder according to the net molar (part) ratio, put them into a ball mill and grind them to disperse them evenly, and then dry them to prepare Obtain the tin dioxide-based composite nanometer gas-sensitive material of the present invention.

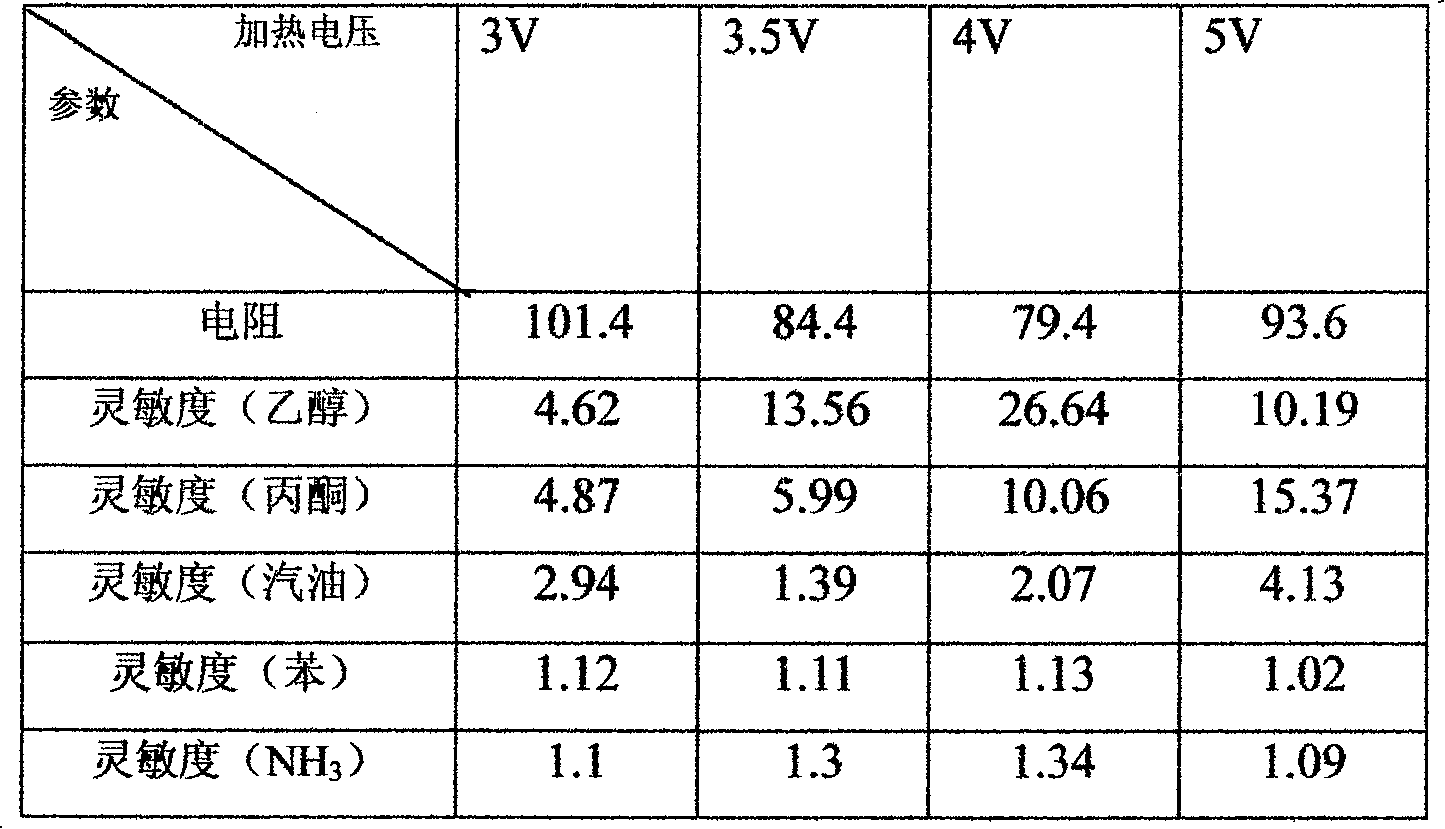

[0018] Using the resistive gas sensor produced by the tin dioxide-based composite nano gas-sensitive material of the present embodiment, the resistance (KΩ) value in the air and the resistance value in 500ppm ethanol, acetone, gasoline, benzene, NH 3 The sensitivity in gas varies with heating voltage parameters as shown in Table 1.

[0019] Table 1:

[0020]

example 2

[0022] Weigh 1 part of tin dioxide-based nanorod grain powder and 0.3 part of tin dioxide-based nano-spherical grain powder according to the net molar (part) ratio, put them into the airflow mixer and stir them, so that the two are evenly dispersed, and the obtained The tin dioxide-based composite nano gas sensitive material of the invention.

[0023] Using the resistive gas sensor produced by the tin dioxide-based composite nano gas-sensitive material of the present embodiment, the resistance (KΩ) value in the air and the resistance value in 500ppm ethanol, acetone, gasoline, benzene, NH 3 The sensitivity in gas varies with heating voltage parameters as shown in Table 2.

[0024] Table 2:

[0025]

example 3

[0027] Weigh 1 part of tin dioxide-based nanorod grain powder and 0.1 part of tin dioxide-based nano-spherical grain powder according to the net molar (part) ratio, put them into a ball mill and grind them to disperse them evenly, and then dry them. Obtain the tin dioxide-based composite nanometer gas-sensitive material of the present invention.

[0028] Using the resistive gas sensor produced by the tin dioxide-based composite nano gas-sensitive material of the present embodiment, the resistance (KΩ) value in the air and the resistance value in 500ppm ethanol, acetone, gasoline, benzene, NH 3 The sensitivity in gas varies with heating voltage parameters as shown in Table 3.

[0029] table 3:

[0030]

[0031] Summarize above-mentioned three specific embodiments and detection experiment result, the inventor draws the following conclusions:

[0032] The resistive gas sensor produced by using the tin dioxide-based composite nano gas sensitive material of the invention has h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com