Method for preparing oriented tungstic trioxide nano-film

A tungsten trioxide and nano-film technology, applied in the field of nanotechnology and new materials, can solve the problems of high cost, low orientation, low crystallinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

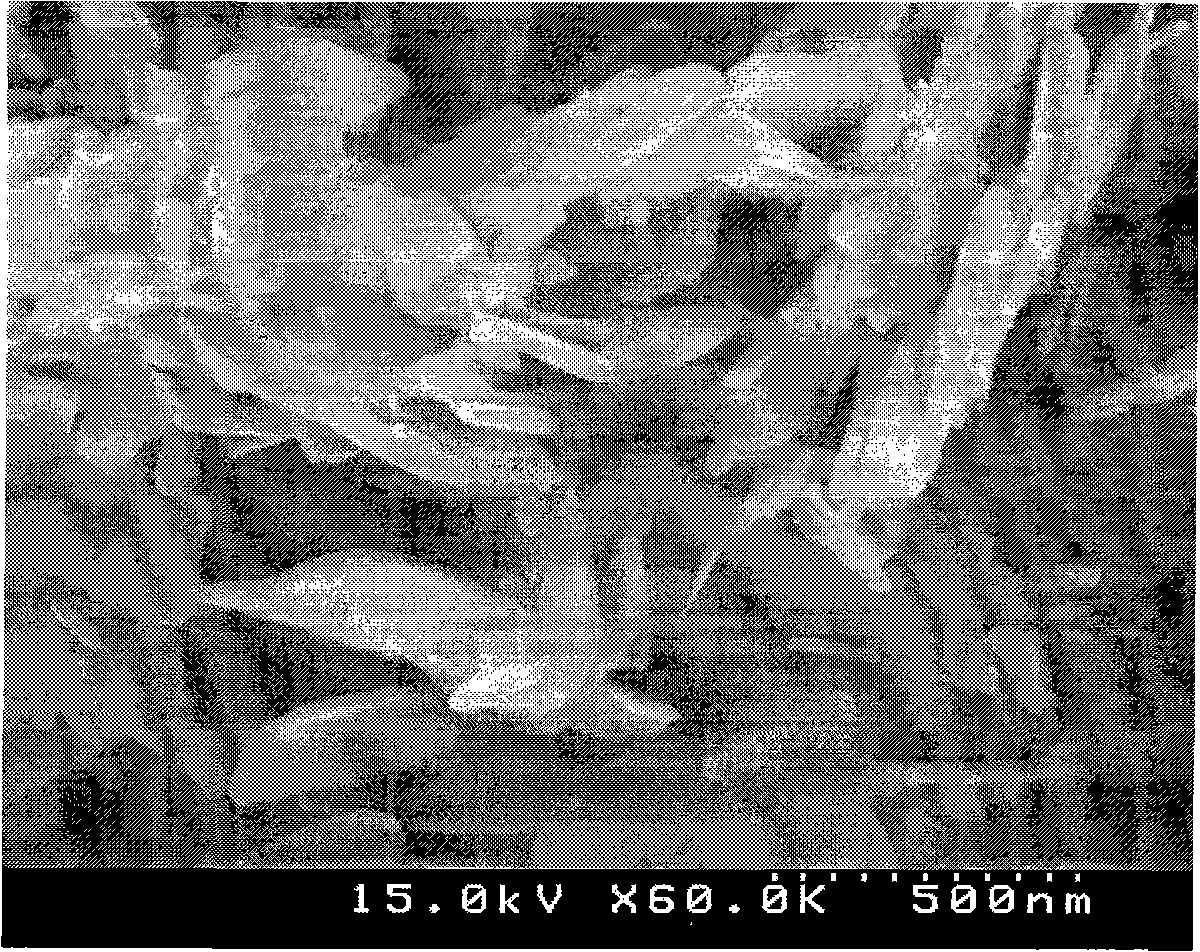

[0021] Take about 20mg of tungsten trioxide (WO 3 ) nanosheets were added to 20ml of absolute ethanol solution, and after ultrasonication for 5min, continued magnetic stirring for 30min to obtain light yellow tungsten trioxide (WO 3 ) nanosheet suspension; take 50 μl of tungsten trioxide (WO 3 ) nanosheet suspension was added dropwise on a horizontally placed copper grid (copper grid used for transmission electron microscope observation); placed in the air for 15min, after the solvent evaporated, repeat the above dripping process; ” The film obtained after the process is as figure 2 shown. It can be found that tungsten trioxide (WO 3 ) nanosheets are evenly placed on the copper grid, and the nanosheets in most areas are double or triple overlapped, while some areas do not have tungsten trioxide (WO 3 ) covered by nanosheets; a single tungsten trioxide (WO 3 ) Selected area electron diffraction patterns of nanosheets such as image 3 Shown, indicating that tungsten triox...

Embodiment 2

[0024] Take about 40 mg of nanosheets and add them to 20 ml of absolute ethanol solution, and after ultrasonication for 5 minutes, continue magnetic stirring for 60 minutes to obtain light yellow tungsten trioxide (WO 3 ) nanosheet suspension; adopt X-ray diffraction to prepare tungsten trioxide (WO 3 ) nano-film substrate, before use, the glass sheet was washed successively with hydrochloric acid, distilled water, acetone, and dried; take 100 μl of tungsten trioxide (WO 3 ) nanosheet suspension was added dropwise on the pre-washed glass plate placed horizontally; placed at room temperature for 30min, after the solvent volatilized, repeat the above drop process; the above "drop-volatilization" process was repeated 10 times and then shallow Yellow tungsten trioxide (WO 3 ) nano film. Figure 6 The resulting tungsten trioxide (WO 3 ) X-ray diffraction line of nano film sample, for convenience comparison, used tungsten trioxide (WO 3 ) X-ray diffraction spectrum of the nanosh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com