Method for improving medium layer defect between micro-reflection mirrors and producing silicon based LCD

A technology of micro-mirror and dielectric layer, which is applied in the direction of equipment, photo-plate making process of patterned surface, optics, etc., can solve the problems of reducing the reflectivity of micro-mirror, affecting the quality of micro-mirror, etc., and achieve the increase of opening width, Effect of reducing diffuse reflection and increasing reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

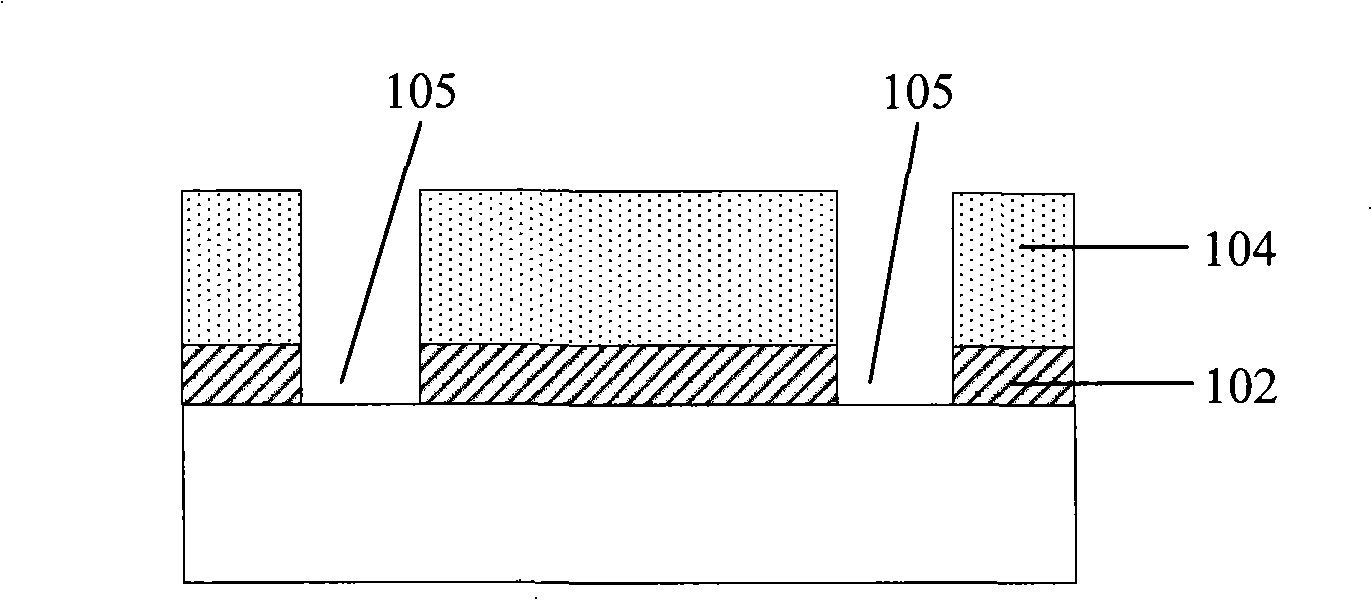

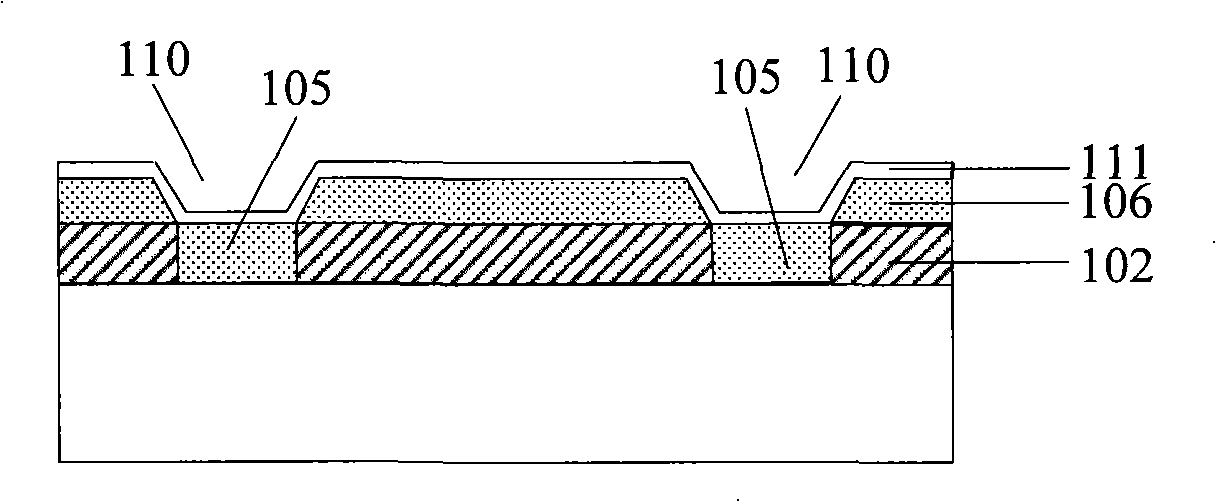

[0022] The invention performs acid etching on the dielectric layer, so that the opening aspect ratio of the dielectric layer at the trench is increased, that is, the opening width is increased, and no insulating dielectric is produced on the metal layer connected to the trench in the subsequent etching process. The layered side wall reduces the diffuse reflection of the micro-mirror and improves the reflectivity of the micro-mirror.

[0023] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

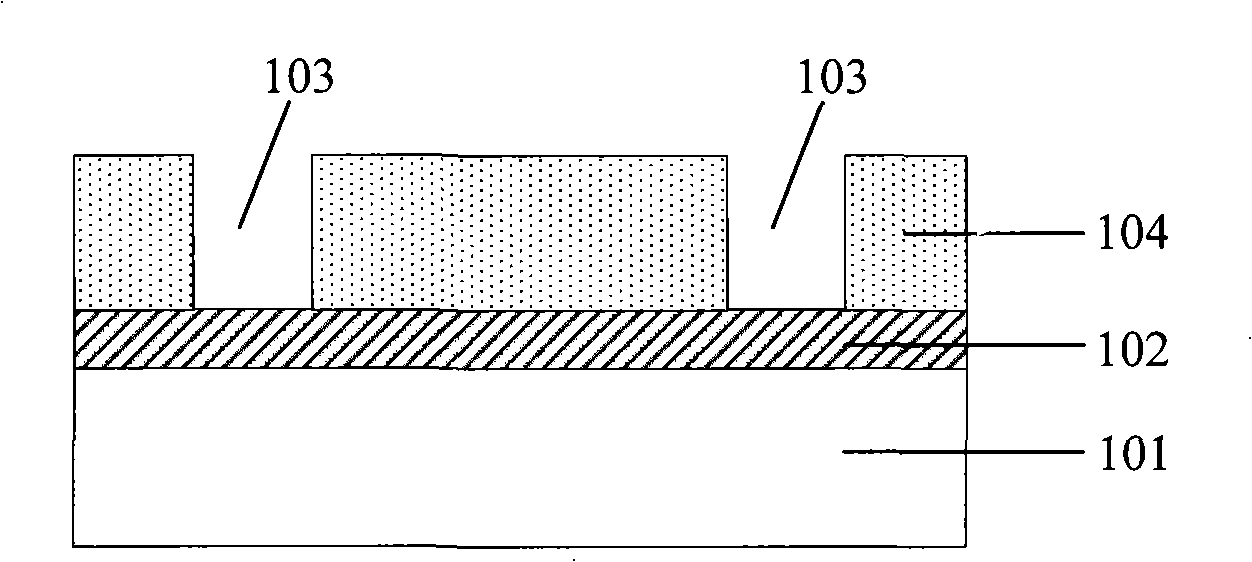

[0024] Figure 6 It is a flow chart of an embodiment of the present invention to improve the defect of the dielectric layer between the micro-mirrors. Such as Figure 6 As shown, step S101 is executed, first, a silicon substrate with a metal layer is provided, and the metal layer includes a trench penetrating the metal layer; step S102 is executed, a dielectric layer is deposited on the metal layer, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com