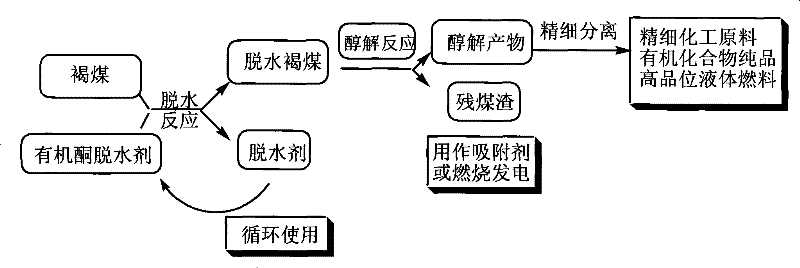

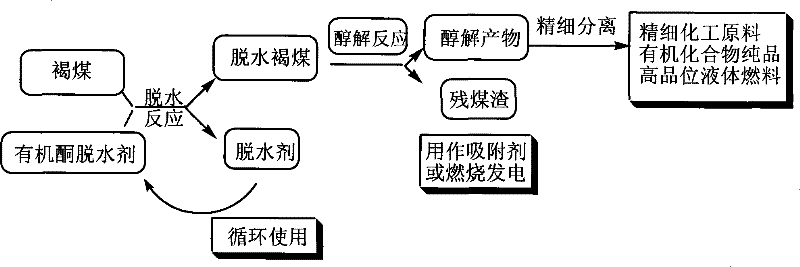

Dehydration and alcohol depolymerization process for low-disintegration coal in mild condition

A technology of low metamorphic coal and conditions, applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, solid fuels, etc., can solve the problems of high energy consumption and hydrogen consumption of hydrogenation and cracking, difficult preservation of lignite, and low dehydration rate, etc. Achieve the effect of easy recovery and recycling, high added value of products, and clean process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Solvent Extraction of First Lignite Effective Dehydration and Recovery of Dehydration Solvent:

[0017] Add 400ml of mixed solvent of acetone and butanone in equal proportions and 400g of pre-ground 100-mesh lignite powder into a 1L reaction kettle, control the dehydration temperature in the kettle at 70°C, fully stir and keep warm for 2 hours, and then use the air pump In the way of pressure, the dehydrated lignite is completely separated from the dehydrated water through the filter plate attached to the reaction kettle, and the organic dehydration solvent in the dehydrated water is obtained by distillation at 120°C and recycled.

[0018] Supercritical alcoholysis of the second lignite and thermal filtration of alcoholysis heat solubles:

[0019] Put methanol and dehydrated lignite in a ratio of 3:1 into a pressure-resistant reactor with a stainless steel microporous filter plate at the bottom, and carry out supercritical alcoholysis of lignite for 4 hours under magnet...

Embodiment 2

[0025] (1) The recovery of effective dehydration and dehydration solvent of the solvent extraction of lignite:

[0026] Add 2L of organic dehydration solvent and about 1000g of 200 mesh lignite powder into a 5L reaction kettle, set the temperature at 90°C for 2 hours and stir thoroughly, and use distillation at 130°C to distill out water, Coal organic extracts and recyclable organic dehydration solvents;

[0027] (2) supercritical alcoholysis of lignite and thermal filtration of alcoholysis hot melt;

[0028] Add methanol and dehydrated lignite in a ratio of 1:1 into a pressure-resistant reaction kettle with a stainless steel microporous (pore size ≤ 0.8 micron) filter plate at the bottom, set the temperature at 300°C under magnetic stirring, and the working pressure at 15MPa. After 2 hours, open the valve connected to the extractor at the lower part of the filter plate, and use the pressure in the kettle to filter the hot melt through the filter plate into the extractor unde...

Embodiment 3

[0032] 1) Solvent extraction of lignite for effective dehydration and recovery of dehydration solvent:

[0033] Add 4000ml of organic dehydration solvent and 5000g of 150-mesh lignite powder into a 10L reaction kettle, set the temperature at 50°C for 5 hours and stir thoroughly, and use distillation at 100°C to distill water and coal from the solvent extraction mixed solution in sequence Organic extracts and recyclable organic dehydration solvents;

[0034] 2) supercritical alcoholysis of lignite and thermal filtration of alcoholysis hot melt;

[0035] Add methanol and dehydrated lignite in a ratio of 5:1 into a pressure-resistant reaction kettle with a stainless steel microporous (pore diameter≤0.8 micron) filter plate at the bottom, set the temperature within 270°C under magnetic stirring, and work at a pressure of 10MPa. After 5 hours of reaction time, open the valve connected to the extractor at the lower part of the filter plate, and use the pressure in the kettle to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com