Titanium dioxide thin film and preparation thereof

A titanium dioxide and thin film technology, which is applied in the field of preparation of the titanium dioxide thin film, can solve the problems of high production cost, complex process, time-consuming and laborious, etc., and achieve the effects of low cost, uniform film formation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

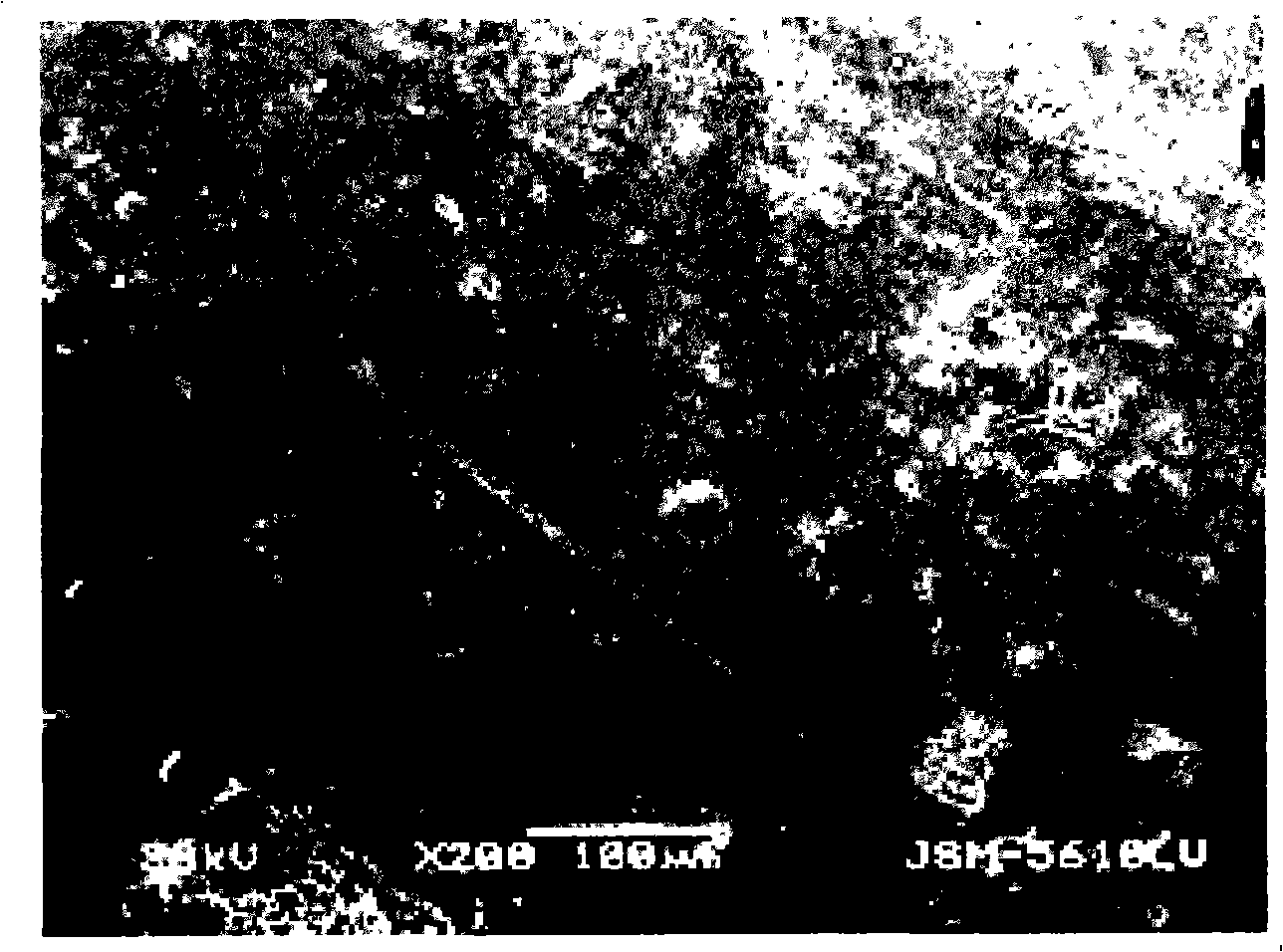

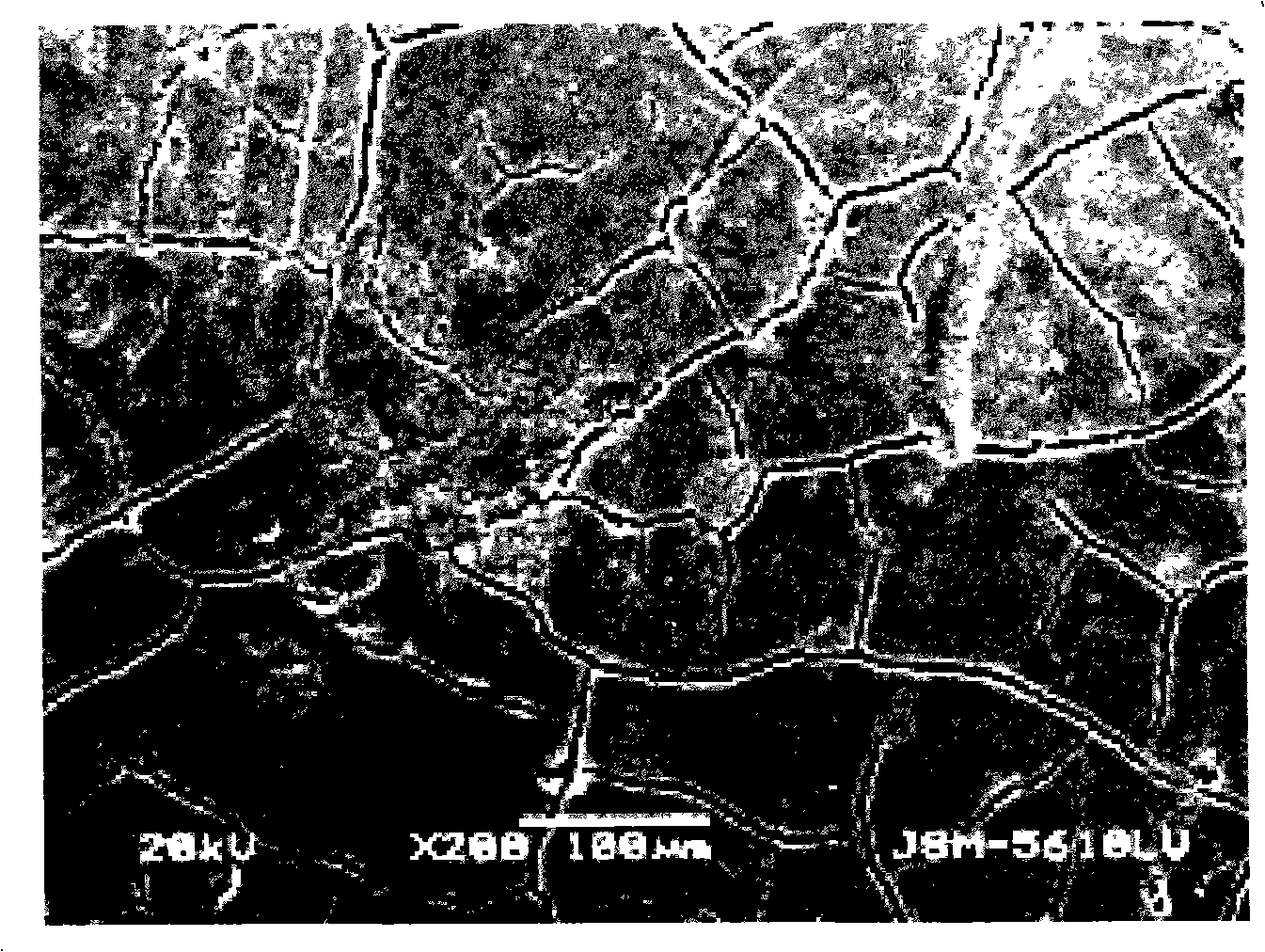

[0023] Take 3gTiO 2 , 0.15g of polyethylene glycol 2000, 0.3mL of acetylacetone, 0.5mL of nitric acid, and 5mL of deionized water were mixed and slowly ground, and then the remaining 1mL of deionized water was slowly added to it in a small amount. After grinding for 50 minutes, 0.08mL of koji was added. After pulling through the OP-10 emulsifier, continue grinding for 20 minutes to obtain the required titanium dioxide slurry. Tape around the sides of the conductive glass to form a groove, see image 3 . Scrape the above slurry on the conductive glass with a scalpel, and dry the prepared film at room temperature for 24 hours. Put the dried film in a muffle furnace for sintering, raise the temperature from room temperature to 120°C at a rate of 1°C / min, keep it for 30 minutes, then raise it to 450°C at a rate of 2°C / min, keep it for 30 minutes, anneal, and cool to room temperature A titanium dioxide film with a thickness of 8 microns was obtained. The 200 times SEM photo of ...

Embodiment 2

[0025] Take 4g TiO2, 1.2g polyethylene glycol 2000, 0.3mL acetylacetone, 1.2mL nitric acid, 8mL deionized water and mix them slowly, then slowly add the remaining 12mL deionized water into it, after grinding for 40min, add 0.3 After adding mL Triton OP-10 emulsifier, continue grinding for 30 minutes to obtain the required titanium dioxide slurry. Use slightly thicker tape to fix around the conductive glass to form a groove, see image 3 . Scrape the above slurry on the conductive glass with a scalpel, and dry the prepared film at room temperature for 12 hours. Put the dried film in a muffle furnace for sintering, raise the temperature from room temperature to 100°C at a rate of 2°C / min, keep it for 40 minutes, then raise it to 499°C at a rate of 5°C / min, keep it for 45 minutes, anneal, and cool to room temperature A titanium dioxide film with a thickness of 18 microns was obtained

Embodiment 3

[0027] Take 3gTiO 2 , 0.6g of polyethylene glycol 2000, 0.04mL of acetylacetone, 0.45mL of nitric acid, and 10mL of deionized water were mixed and slowly ground, and then the remaining 8mL of deionized water was slowly added in a small amount. After grinding for 60 minutes, 0.4mL of koji was added. After pulling through the OP-10 emulsifier, continue grinding for 10 minutes to obtain the required titanium dioxide slurry. Tape around the sides of the conductive glass to form a groove, see image 3 . Scrape the above slurry on the conductive glass with a scalpel, and dry the prepared film at room temperature for 48 hours. Put the dried film in a muffle furnace for sintering, raise the temperature from room temperature to 150°C at a rate of 1°C / min, keep it for 20 minutes, then raise it to 440°C at a rate of 10°C / min, keep it for 60 minutes, anneal, and cool to room temperature A titanium dioxide film with a thickness of 12 micrometers was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com