Process for double-aqueous-phase extracting and refining persimmon lycopene

A lycopene, two-phase technology, applied in extraction purification/separation, organic chemistry and other directions, can solve the problems of affecting the market competitiveness of lycopene, high production cost, poor product quality, etc. The effect of less pollution and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

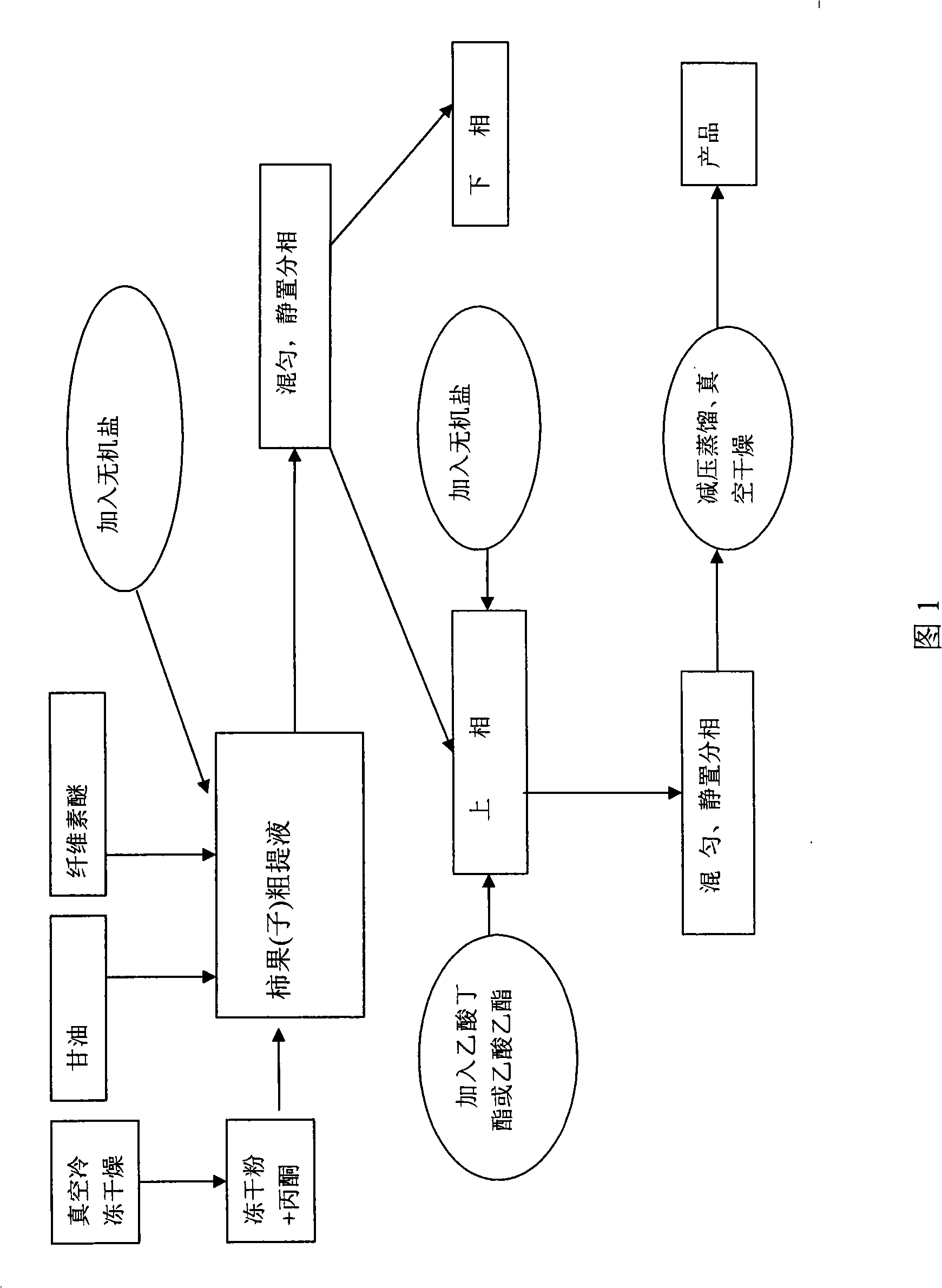

Image

Examples

Embodiment 1

[0029] Step 1. Vacuum freeze-drying: sort and clean fresh persimmon fruits (seeds), take 160g and cut them into 5mm square and 10mm thick blocks, put them on a plate, and pre-freeze them at -20°C with a pre-freezing rate of 0.03 hours / mm , at a vacuum degree of 20 Pa, a heating plate at 25° C., sublimation drying and analysis drying at a cold trap of -35° C., to obtain 10 g of freeze-dried persimmon fruit (seed) grains.

[0030] Step 2, crude organic solvent extraction: crush 10 g of vacuum freeze-dried persimmon fruit (seeds), add 100 mL of acetone, perform solid-liquid extraction for 3 hours, and obtain 68 mL of crude lycopene extract after filtration.

[0031] Step 3, two-phase extraction and refining: take 68mL of the above crude lycopene extract, add 10g cellulose methyl ether, 10g glycerin, 50mL water, and then add 1g MgCl 2 , mix well, and separate the phases at 15°C for 3 hours.

[0032] Step 4, ethyl acetate stripping: take out 55mL of cellulose methyl ether phase ri...

Embodiment 2

[0034] Step 1. Vacuum freeze-drying: sort and clean fresh persimmon fruit (seeds), take 160g and cut into 5mm square, 15mm thick blocks, put them on a plate, and pre-freeze them at -25°C with a pre-freezing rate of 0.05 hours / mm , at a vacuum degree of 18Pa, a heating plate at 25°C, and a cold trap at -35°C for sublimation drying and analysis drying to obtain 10 g of freeze-dried persimmon fruit (seed) grains.

[0035] Step 2, crude organic solvent extraction: pulverize 10 g of vacuum freeze-dried persimmon fruit (seeds), add 150 mL of acetone, perform solid-liquid extraction for 3 hours, and obtain 102 mL of crude lycopene extract after filtration.

[0036] Step 3, two-phase extraction and refining: take 102mL of the above lycopene crude extract, add 15g of cellulose methyl ether, 12g of glycerin, 60mL of water, and then add 2g of MgCl 2 , mix well, and separate the phases at 30°C for 6 hours.

[0037] Step 4, ethyl acetate stripping: take out 75mL of cellulose methyl ether ...

Embodiment 3

[0040] Step 1. Vacuum freeze-drying: sort and clean fresh persimmon fruits (seeds), take 160g and cut them into 5mm square and 15mm thick blocks, put them on a plate, and pre-freeze them at -25°C with a pre-freezing rate of 0.04 hours / mm , at a vacuum degree of 20 Pa, a heating plate at 25° C., sublimation drying and analysis drying at a cold trap of -35° C., to obtain 10 g of freeze-dried persimmon fruit (seed) grains.

[0041] Step 2, crude organic solvent extraction: crush 10 g of vacuum freeze-dried persimmon fruit (seeds), add 180 mL of acetone, perform solid-liquid extraction for 3 hours, and obtain 76 mL of crude lycopene extract after filtration.

[0042] Step 3, two-phase extraction and refining: Take 76 mL of the crude lycopene extract, add 24 g of cellulose ether, 18 g of glycerin, 70 mL of water, and then add 3 g of NaCl, mix well, and separate phases at 25 ° C for 5 hours.

[0043] Step 4, butyl acetate stripping: Take out 65 mL of the cellulose ether phase rich i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com