Solid-oxide fuel battery cathode powder preparation method

A fuel cell cathode and solid oxide technology, which is applied in the field of solid oxide fuel cell cathode powder preparation, can solve the problems of difficult large-scale production, long process flow, complex process, etc., to improve the preparation rate and yield, and the process is reasonable The effect of simple, simple preparation and operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

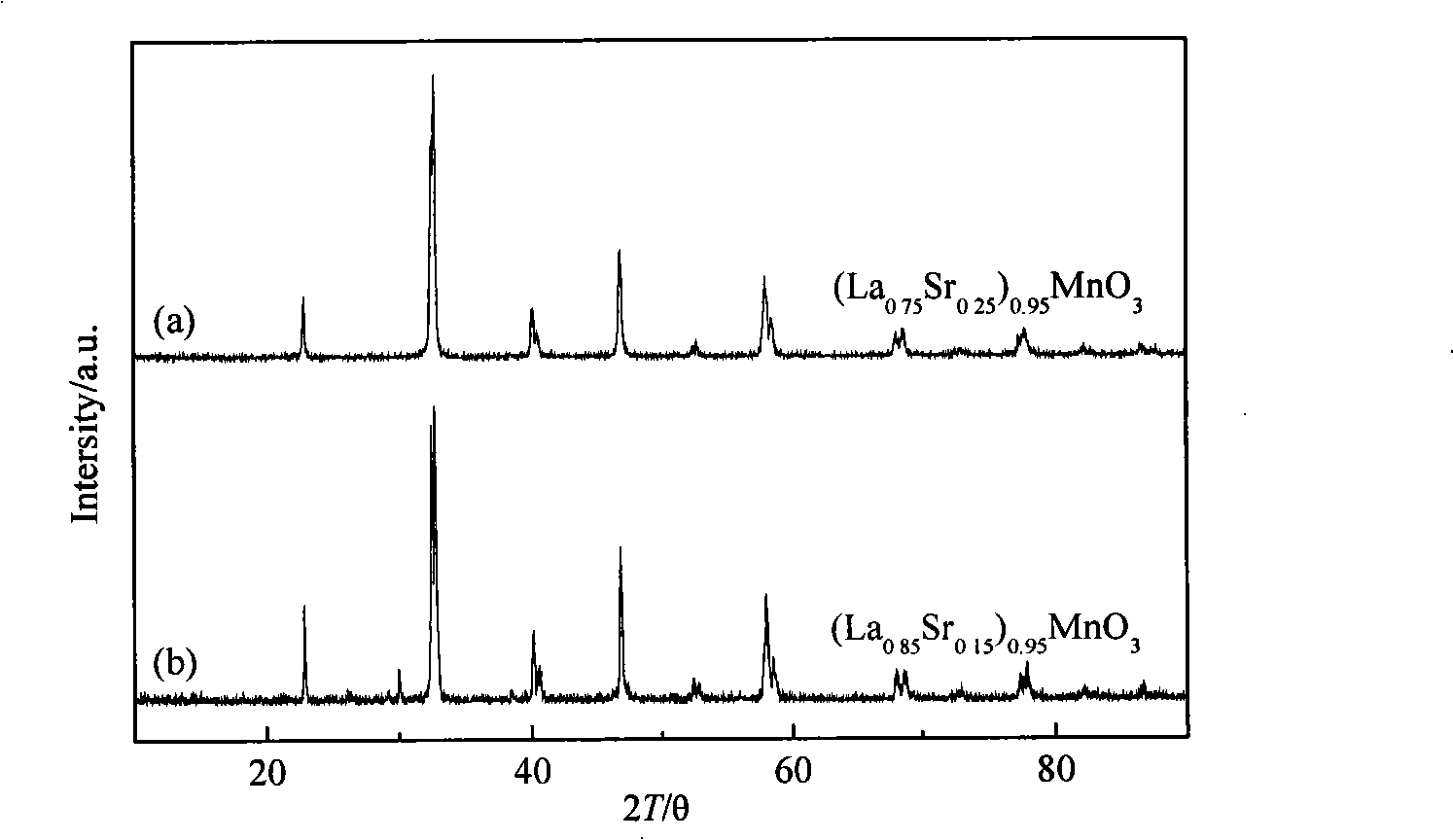

Embodiment 1

[0019] Preparation (La 0.75 Sr 0.25 ) 0.95 MnO 3 cathode powder. The raw material is composed of 69.918g of lanthanum nitrate+6.031g of strontium nitrate+71.567g of 50% manganese nitrate solution, wherein lanthanum nitrate and manganese nitrate are dissolved in 1000ml of industrial ethanol, and strontium nitrate is dissolved in 100ml of deionized water. Subsequently, the deionized water solution was poured into the solution with industrial ethanol as the solvent, and mixed well. During the spray drying process, the inlet temperature is set to 120-125°C, and the test spraying is started when the outlet temperature is >96°C. After the test spraying is stable, that is, the outlet temperature is >78°C and then the formal spray drying is carried out. Adjust the feeding speed of the feed liquid to 10-13ml / min, the gas pressure is 7-8l / min, and the outlet temperature is 79-84°C during the spraying process.

[0020] After the spray drying is completed, the powder is collected, an...

Embodiment 2

[0022] Preparation (La 0.85 Sr 0.15 ) 0.95 MnO 3 cathode powder. The raw material composition is 69.918g of lanthanum nitrate+6.031g of strontium nitrate+71.567g of 50% manganese nitrate solution, and the nitrate solution is dissolved in 1000ml of deionized water. During the spray drying process, the inlet temperature is set to 220-230°C, and the test spraying is started when the outlet temperature is >150°C. After the test spraying is stable, that is, the outlet temperature is >100°C and then the formal spray drying is carried out, and the feeding speed of the feed liquid is adjusted to 16.7ml / min, the gas pressure is 10-11.5l / min, and the outlet temperature is >95°C during the spraying process.

[0023] After the spray drying is completed, the powder is collected, and then put into a box-type resistance furnace at 1000°C for calcination. Roasting is divided into two stages: the first stage temperature control program is heating from room temperature to 700°C, and then l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com