Method for performing ultrasonic-assisted supercritical carbon dioxide extraction on vanilla bean essential oil

A technology of vanilla bean extract and carbon dioxide, which is applied in the directions of essential oils/spices, chemical instruments and methods, solvent extraction, etc., can solve the problems of changing the flavor and aroma of spices, and achieve accelerated diffusion speed, high production efficiency, and production short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

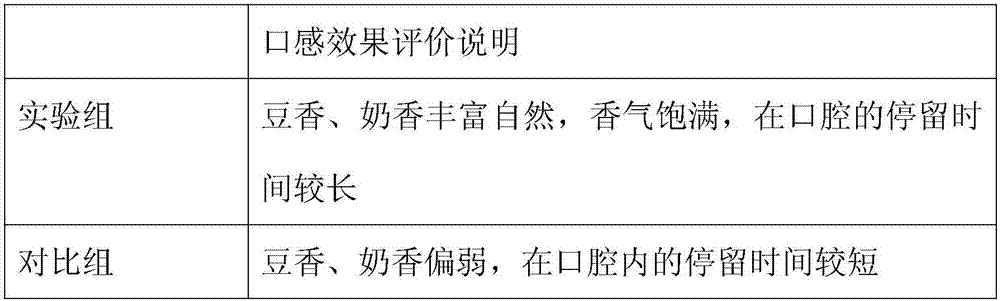

Examples

Embodiment 1

[0023] Crush the vanilla beans and sieve the 60-70 mesh powder; put the vanilla bean powder obtained by the above sieving into the ultrasonic equipment, add absolute ethanol, the solid-liquid ratio is 1:1, and the ultrasonic treatment temperature is normal temperature, power 200W, the time is 4min; then put the vanilla beans after ultrasonic treatment into supercritical CO 2 In the extraction kettle, adjust the temperature, pressure and time required for extraction to carry out extraction, wherein: the pressure of the extraction kettle is set to 10MPa, the temperature is 35°C, the time is 160min, the flow rate of supercritical carbon dioxide is 20L / h, the first separation The separation pressure of the tank is set to 6.0MPa, and the separation temperature is set to 35.0°C; the separation pressure of the second separation tank is set to 4.0MPa, and the separation temperature is set to 25.0°C; the extraction is collected from the first separation tank solution, weighed to obtain...

Embodiment 2

[0025] Crush the vanilla beans and sieve the 70-80 mesh powder; put the vanilla bean powder obtained by the above sieving into the ultrasonic equipment, add anhydrous ethanol propylene glycol 50:50 mixed solution, solid-liquid ratio 1:0.6, ultrasonic The treatment temperature is normal temperature, the power is 300W, and the time is 6min; then the ultrasonically treated vanilla beans are put into supercritical CO 2 In the extraction kettle, adjust the temperature, pressure and time required for extraction to carry out extraction, wherein: the pressure of the extraction kettle is set to 12MPa, the temperature is 40°C, the time is 170min, the flow rate of supercritical carbon dioxide is 16L / h, the first separation The separation pressure of the tank is set to 6.0MPa, and the separation temperature is set to 35.0°C; the separation pressure of the second separation tank is set to 4.0MPa, and the separation temperature is set to 25.0°C; the extraction is collected from the first sep...

Embodiment 3

[0027] Crush the vanilla beans and sieve the 80-90 mesh powder; put the vanilla bean powder obtained by the above sieving into an ultrasonic device, add a 70:30 mixture of absolute ethanol medium-chain triglycerides, the solid-to-liquid ratio 1:0.8, the temperature of ultrasonic treatment is normal temperature, the power is 400W, and the time is 8min; then the vanilla beans after ultrasonic treatment are put into supercritical CO 2 In the extraction kettle, adjust the temperature, pressure and time required for extraction to carry out extraction, wherein: the pressure of the extraction kettle is set to 14MPa, the temperature is 45°C, the time is 180min, the flow rate of supercritical carbon dioxide is 18L / h, the first separation The separation pressure of the tank is set to 6.0MPa, and the separation temperature is set to 35.0°C; the separation pressure of the second separation tank is set to 4.0MPa, and the separation temperature is set to 25.0°C; the extraction is collected f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com