Anode plate construction of fuel cell

A technology for anode plates and fuel cells, which is applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems of fuel leakage, poor flow field design flexibility, and high cost, and achieve reliable sealing effect and flow field The effect of high design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

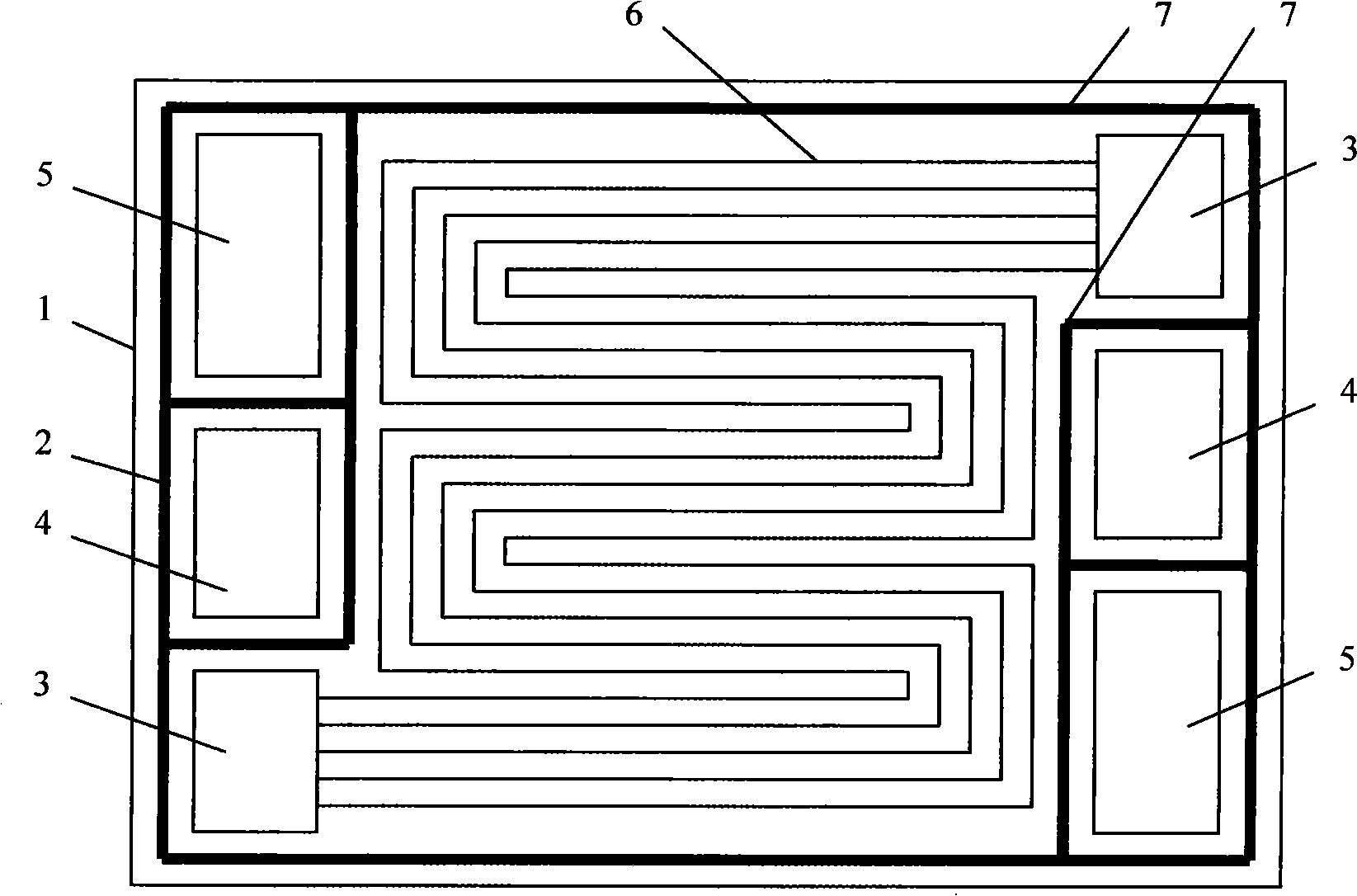

Embodiment 1

[0042] Figure 6 It is a section view viewed from the horizontal direction. It includes an upper half plate 31, a lower half plate 32, a sealing ring 33 partially embedded in the upper surface of the upper half plate, an adhesive 34, a longitudinal fuel main channel 35, a longitudinal oxidant main channel 36, and a penetrating upper half plate located on the upper surface of the upper half plate. Thick flow field 37, flow channel 38 located on the upper surface of the lower half plate, anode diffusion layer 39, membrane electrode 40, cathode diffusion layer 41, upper and lower layers of adhesive tape 42.

[0043] The relationship between the anode diffusion layer 39, the membrane electrode 40, the cathode diffusion layer 41, and the upper and lower layers of adhesive tape 42 is the same as that of the known technology. Covering in the upper and lower directions, the tape plays the role of increasing mechanical strength, sealing, and fixed connection, thus forming a 5-in-1 mem...

Embodiment 2

[0054] like Figure 8 shown. Others are the same as in Embodiment 1, the only difference is that the adhesive 34 is replaced by the sealing ring 45; on the lower surface of the upper half plate and (or) the upper surface of the lower half plate, the corresponding position is provided with a concave cavity for accommodating the sealing ring 45 groove. The sealing ring 45 realizes the sealing between the two half-plates, and the assembly pressing force of the fuel cell realizes the conductive contact.

Embodiment 3

[0056] like Figure 9 shown. Others are all the same as in Example 1, the difference is:

[0057] 1. The flow field 46 that is arranged on the upper surface of the lower half plate and does not penetrate through the thickness of the lower half plate is added. The shape of the flow field 46 is similar to that of the flow field 37, and the positions correspond to each other, thereby increasing the cross-sectional area of the flow field and reducing the resistance of the fuel flow.

[0058] 2. A flow groove 47 arranged on the lower surface of the upper half plate is added, and its position corresponds to the flow groove 38, thereby increasing the cross-sectional area of the flow groove and reducing the resistance of the fuel flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com