Press-type bottle cover

A press-type, bottle cap technology, applied in the field of bottle caps, can solve the problems of hidden leakage, spring fatigue, insufficient sealing force of bottle plugs, etc., and achieve the effect of reliable sealing effect and prevention of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

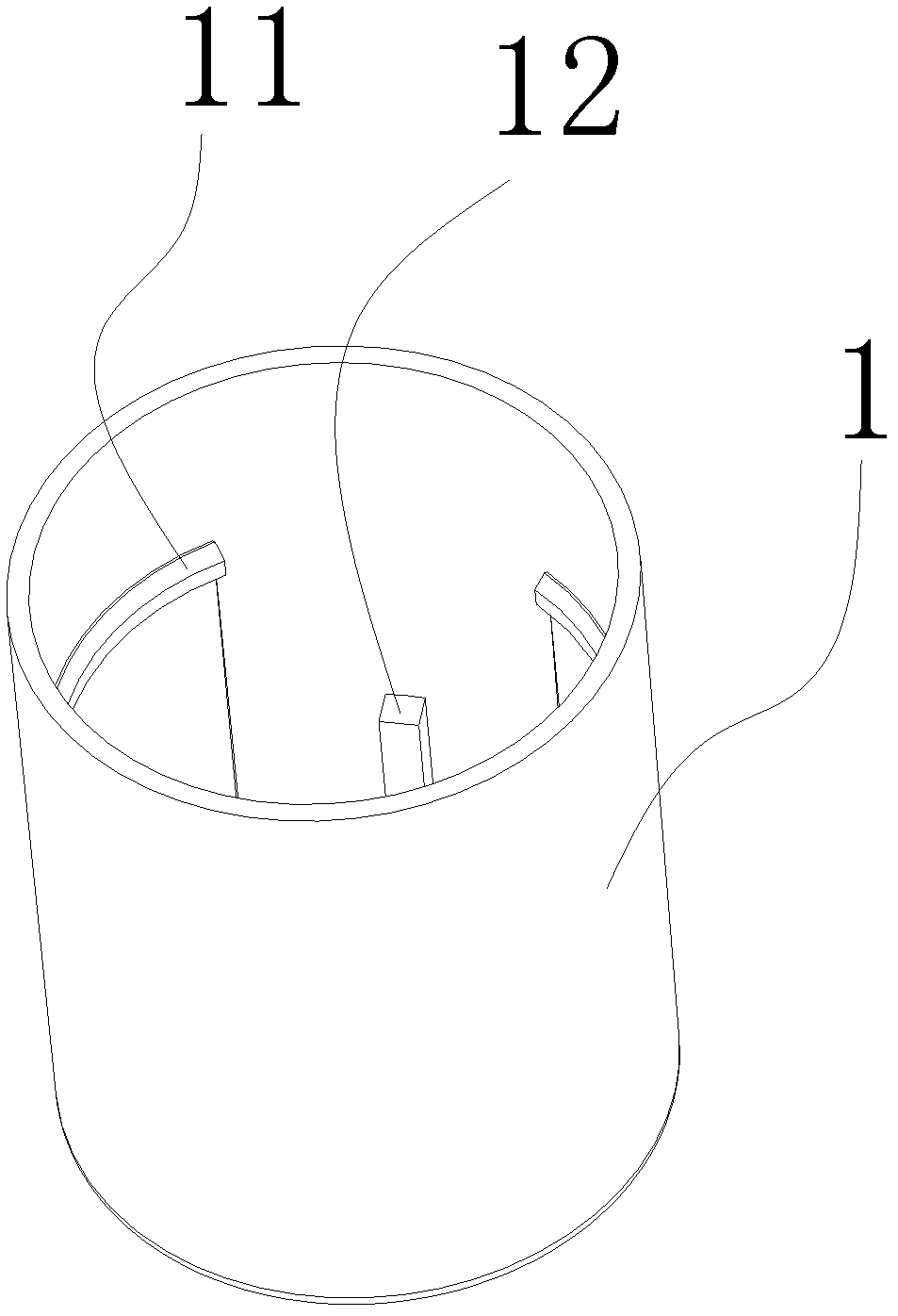

[0022] The present invention will be further described below in conjunction with the drawings.

[0023] Such as figure 1 As shown, the present invention includes a housing 1 and an inner cover 3 rotatably arranged in the housing 1. The inner wall of the inner cover 3 is provided with a thread, and also includes an opening member arranged in the housing 1. The operation of the opening member The end is located outside the housing 1, the opening piece is movably fitted with the housing 1 in the axial direction, and the opening piece is in contact with the inner cover 3 through a rotation stop structure during pressing operation. During installation, first install the opening piece into the casing 1. The opening piece can be fitted with the casing 1 through a guiding structure, such as guide grooves and guiding ribs; or it can be loosely fitted directly into the casing 1. Internal axial movement. Then screw the inner cap 3 onto the threaded bottle mouth 6. Finally, buckle the shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com