Lithium ionic cell composite positive pole material coated by orthosilicate

A composite cathode material, lithium-ion battery technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of poor electrochemical performance of cathode materials, etc. The effect of easy large-scale production and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

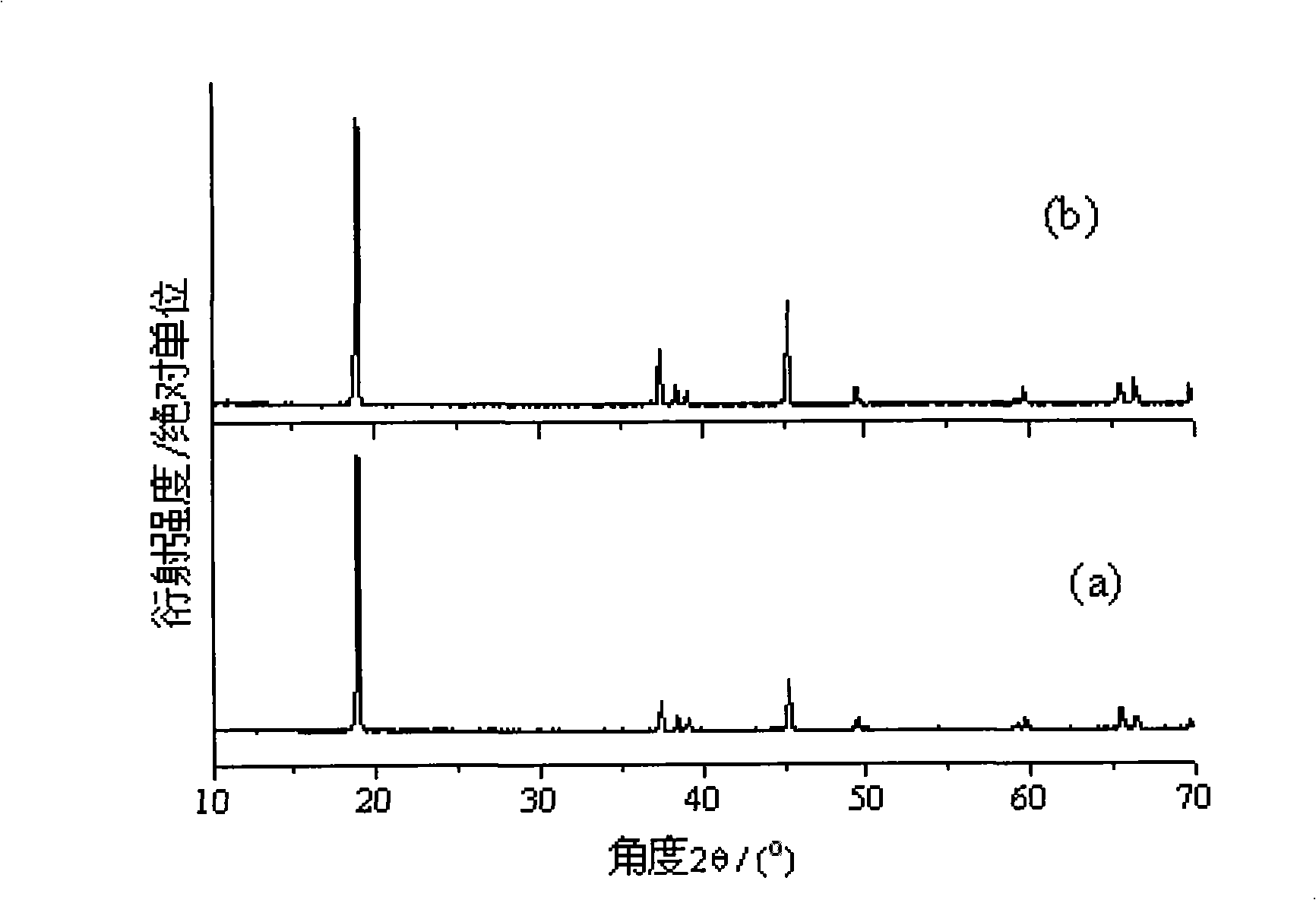

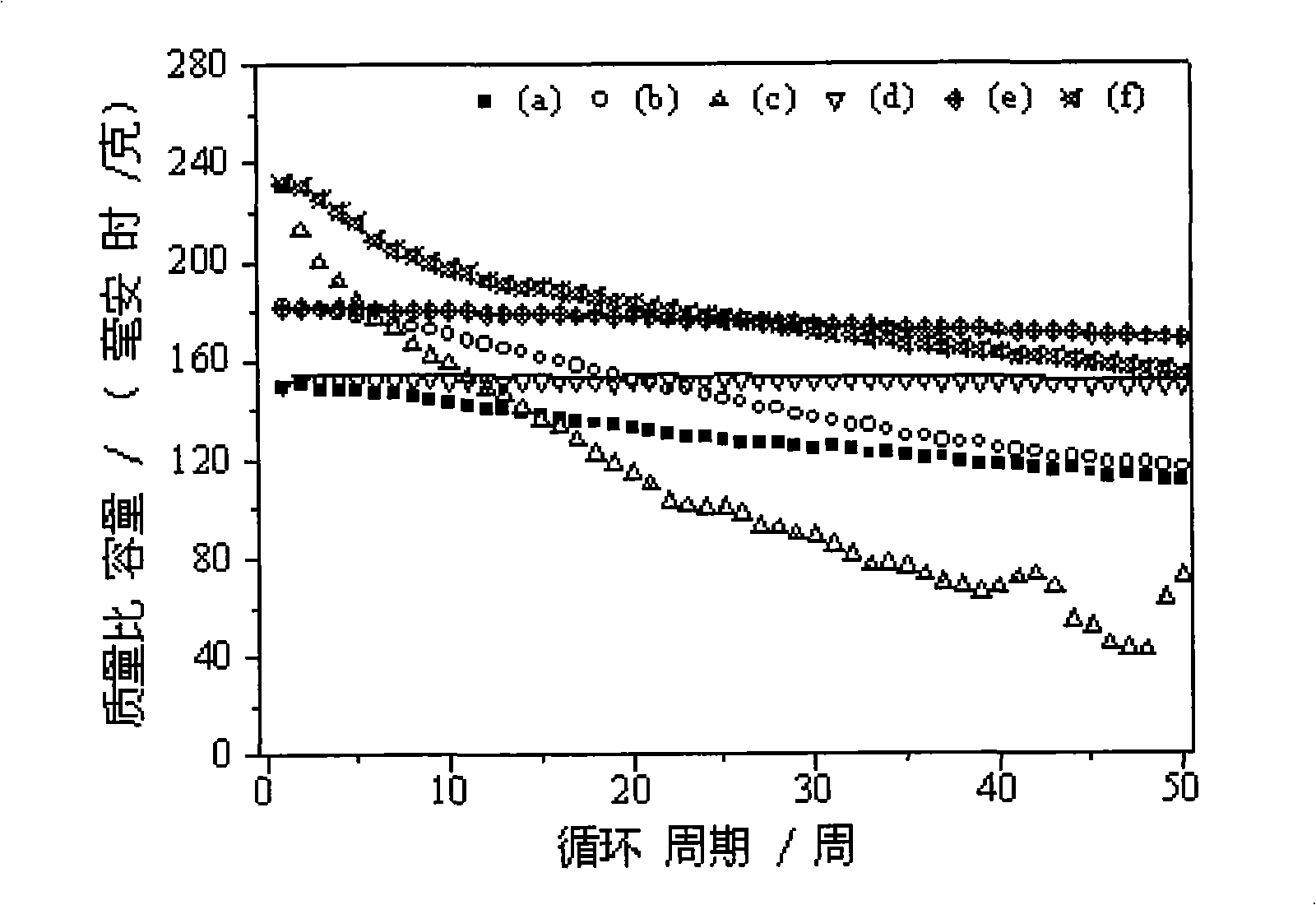

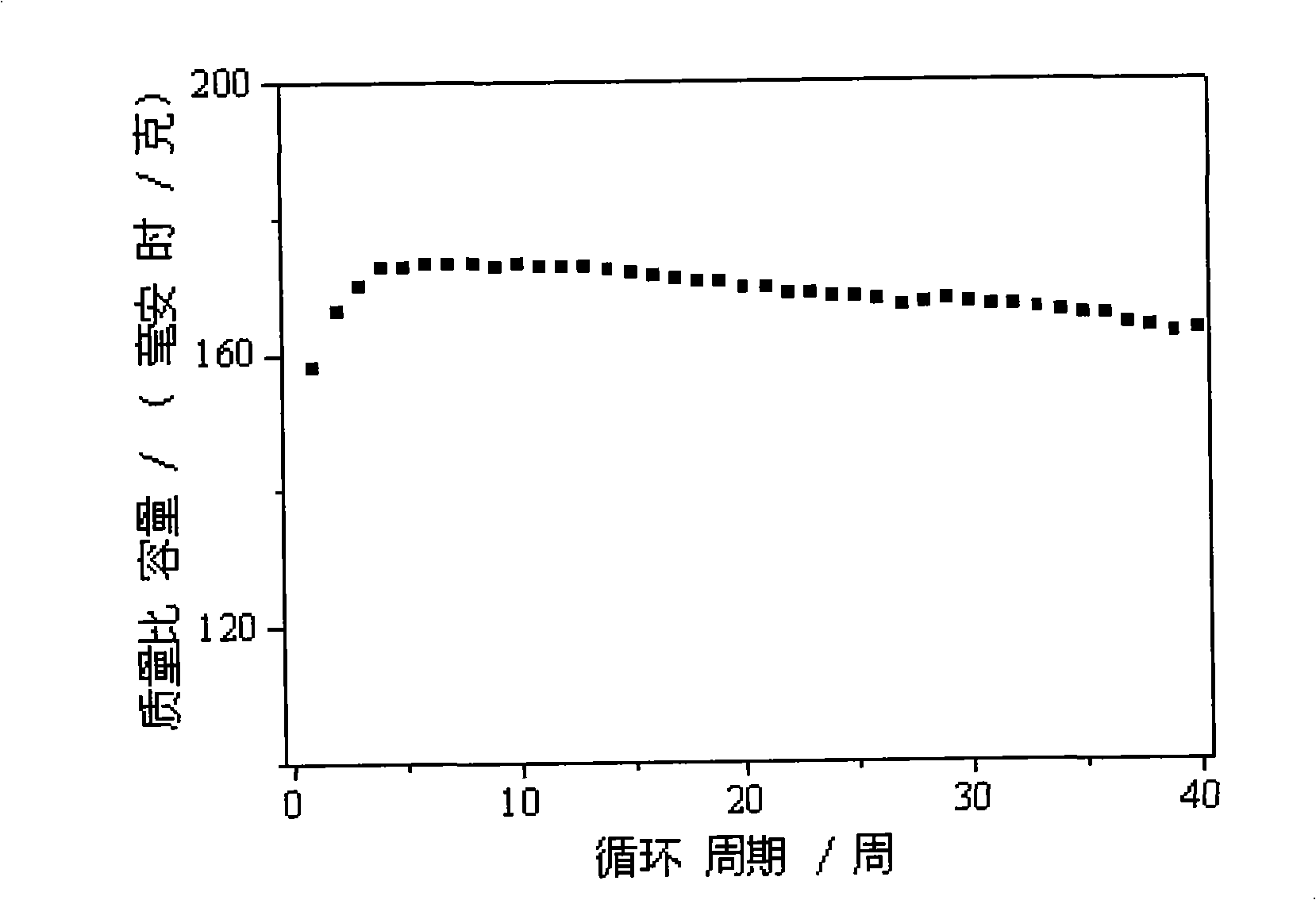

[0027] 1.1791g (4.8mmol) of Mn(CH 3 COO) 2 Dissolve in a mixed solution of 10mL deionized water and 10mL ethanol, reflux and stir at 80°C for 1 hour, add 1.0289g (4.8mmol) of tetraethyl orthosilicate dropwise to the above mixed solution, stir for 12 hours, and 30g cathode material LiCoO 2 Add it, and then mechanically stir for 180 minutes to form a suspension, dry the suspension at 120°C for 12 hours, and then bake the sample at 700°C for 5 hours to obtain MnSiO 4 Coated LiCoO 2 . The coated product was tested by XRD, and the characterization results were as follows: figure 1 As shown, the product is α-NaFeO with a single crystal phase 2 type layered structure. The obtained electrode material was mixed with acetylene black conductive agent and PVDF binder in a mass ratio of 90:5:5, coated on the aluminum foil of the current collector, dried at 80°C, and then used a punching machine to make an electrode sheet with a diameter of 1 cm. The metal lithium sheet is the negati...

Embodiment 2

[0029] 0.9696g (2.4mmol) of Fe(NO 3 ) 3 and 0.2448g (2.4mmol) of CH 3 COOLi was dissolved in a mixed solution of 5mL deionized water and 10mL ethanol. After reflux stirring at 80°C for 0.5 hours, 0.5000g of tetraethyl orthosilicate was added dropwise to the above mixed solution. After stirring for 20 hours, 35g of positive electrode material LiCoO 2 Add it into it, form a suspension after mechanical stirring for 120 minutes, dry the suspension at 150°C for 15 hours, and then bake the sample at 650°C for 8 hours to obtain LiFeSiO 4 Coated LiCoO 2 Material. The XRD test of the coating material shows that the product is α-NaFeO with a single crystal phase 2 type layered structure, electrochemical tests and thermal analysis results show that LiFeSiO 4 Coated LiCoO 2 The material has good anti-overcharge performance and thermal stability.

Embodiment 3

[0031] 1.3522g (8.0mmol) of MnSO 4 ·H 2 O was dissolved in a mixed solution of 15mL deionized water and 10mL ethanol, and after reflux and stirring at 90°C for 2 hours, 1.6666g (8.0mmol) ethyl tetrasilicate was added dropwise to the above mixed solution, and after stirring for 8 hours, the 30g cathode material LiCoO 2 Add it into it, form a suspension after mechanical stirring for 120 minutes, dry the suspension at 100°C for 10 hours, and then bake the sample at 700°C for 8 hours to obtain MnSiO 4 Coated LiCoO 2 . The XRD test of the coated product shows that the product is α-NaFeO with a single crystal phase 2 type layered structure, electrochemical tests and thermal analysis results show that MnSiO 4 Coated LiCoO 2 It has good anti-overcharge performance and thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com