Water dispersion of self-drying acrylic modified alkyd resin industrial topcoat using the water dispersion as base

An alkyd resin and acrylic technology, which is applied in the field of coatings, can solve the problems of poor film-forming and decorative properties, poor water resistance of paint films, and poor resistance to hydrolysis of resins, and achieves the effects of good decorative properties, good film-forming properties and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

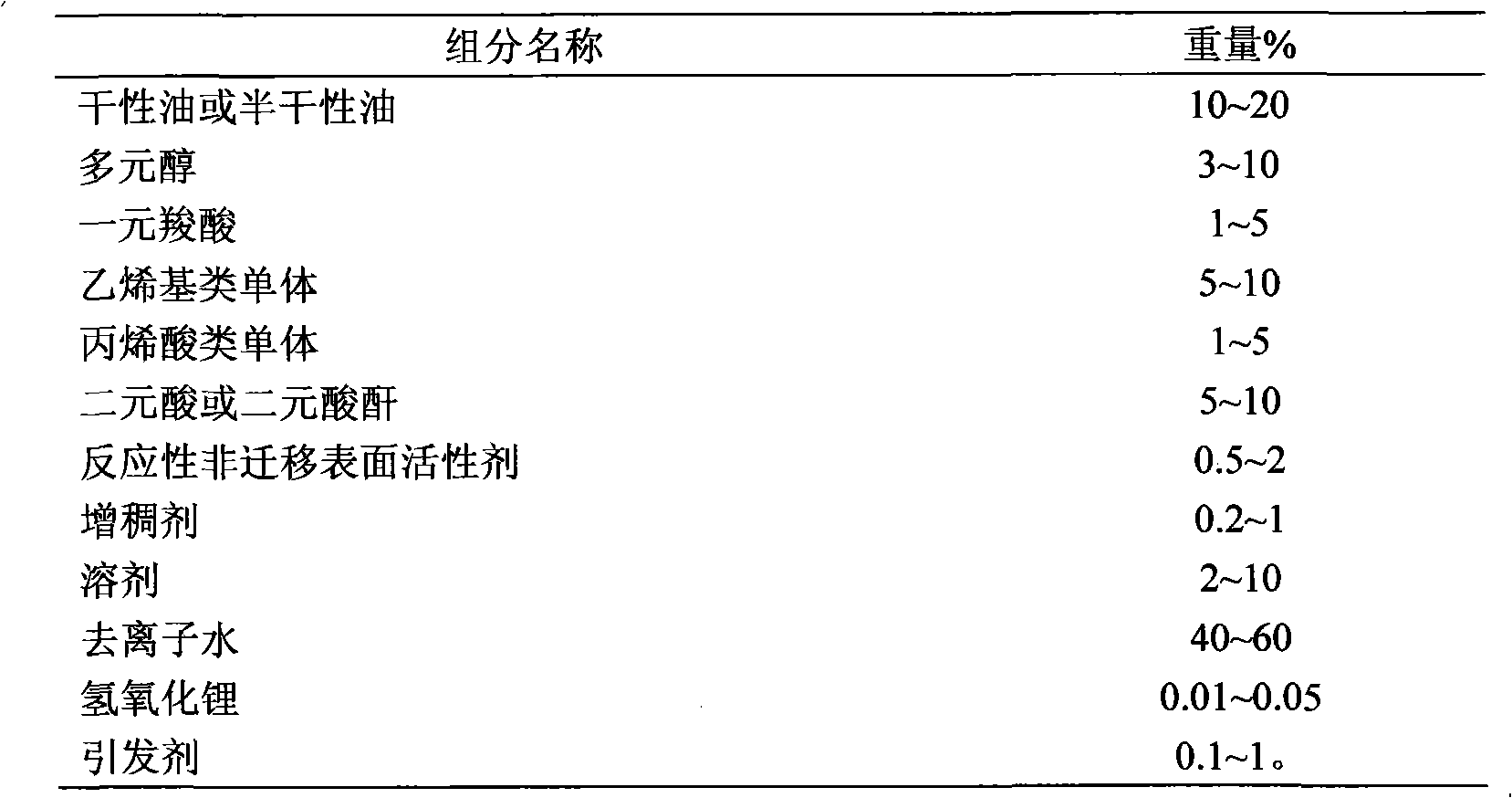

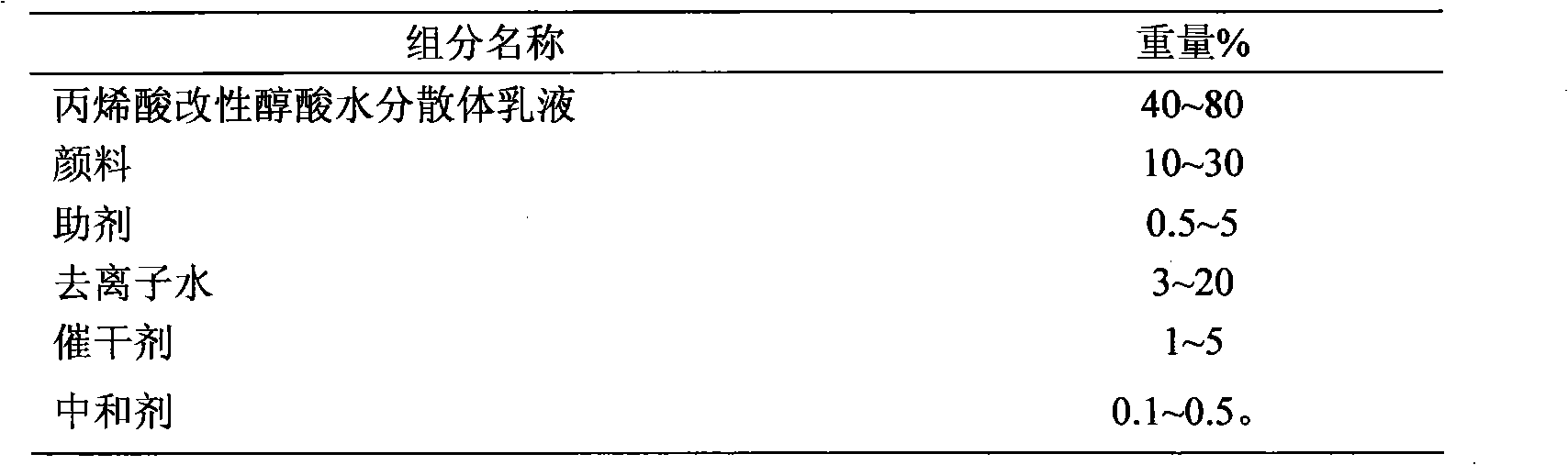

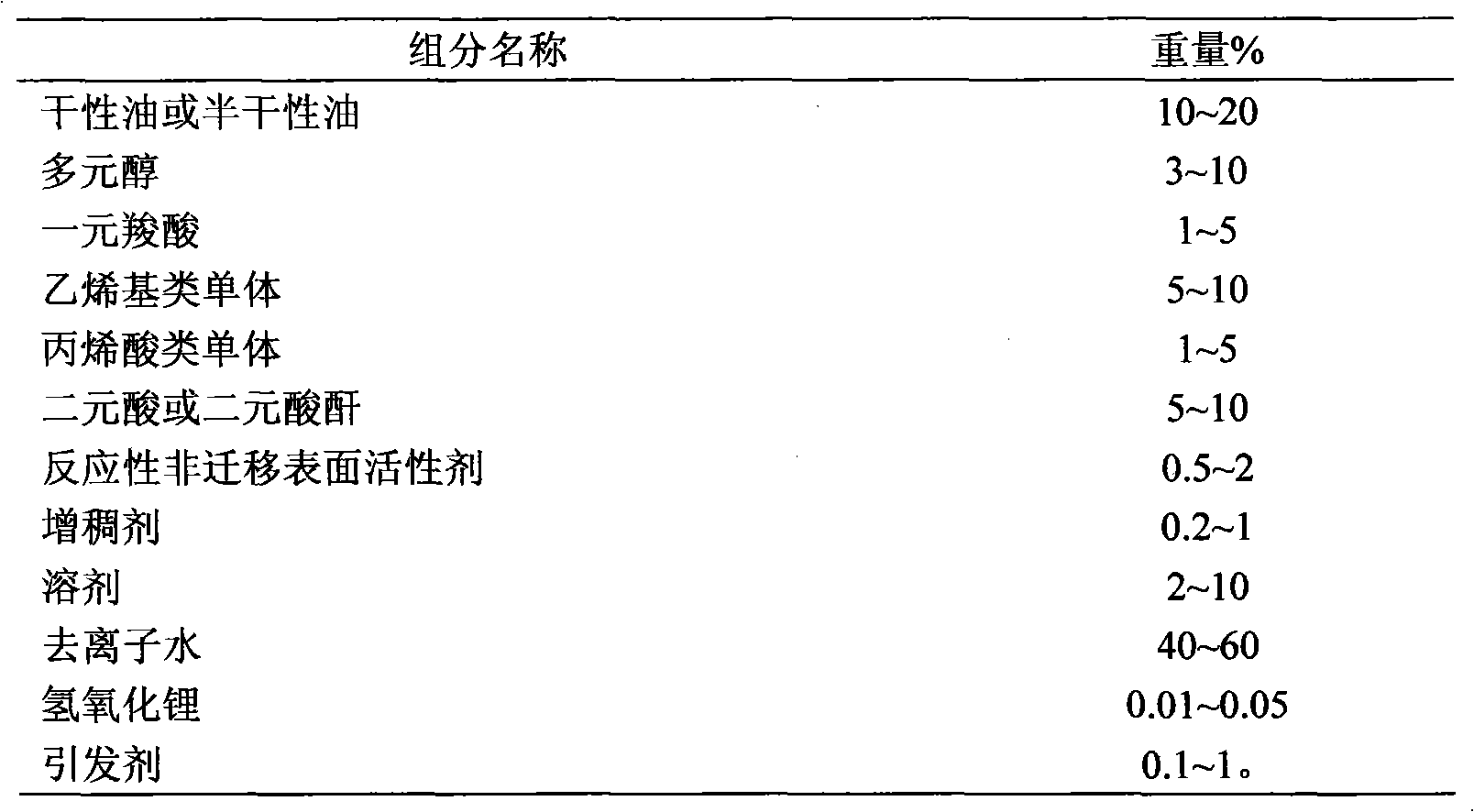

Method used

Image

Examples

Embodiment 1

[0028] 800 g of xylene was put into the four-neck flask, and the temperature was raised to reflux. Mix 720g of styrene, 135g of vinyl tertiary carbonate, 45g of acrylic acid, and 45g of benzoyl peroxide, and mix them evenly. After the benzoyl peroxide (BPO) is completely dissolved, add the materials dropwise, and drop them for 5 hours under reflux. Finished, and then keep warm for 1.5 hours. Continue to add dropwise the mixed solution of 100 g of xylene and 10 g of benzoyl peroxide, and finish dropping in 1 hour under reflux, and then keep the temperature for 2 hours, then the material can be discharged and used as an acrylic acid prepolymer for subsequent use.

Embodiment 2

[0030] 800 g of xylene was put into the four-neck flask, and the temperature was raised to reflux. Mix 720g of styrene, 135g of butyl acrylate, 45g of methacrylic acid, and 45g of benzoyl peroxide evenly. After the BPO is completely dissolved, add the material in a dropwise manner. Drop it in reflux for 4 hours, and then keep it warm for 1.5 hours . Continue to add dropwise the mixed solution of 100 g of xylene and 10 g of benzoyl peroxide, and finish dropping in 1 hour under reflux, and then keep the temperature for 2 hours, then the material can be discharged and used as an acrylic acid prepolymer for subsequent use.

Embodiment 3

[0032] Add 334 g of linseed oil into the reaction flask, and after passing through nitrogen for 10 minutes, start to stir and heat up. When the temperature is raised to 160°C, add 103g of pentaerythritol, 0.2g of lithium hydroxide and 0.1g of antioxidant in turn, continue to heat up to 240°C, and maintain the alcoholysis at this temperature until the volume ratio of the alcoholyzate to ethanol is 1: When the mixture of 3 remains transparent, it is the end point of alcoholysis. Cool down to 180°C, add 64g of benzoic acid, 450g of acrylic acid prepolymer of Example 1 and 0.1g of antioxidant in sequence, gradually raise the temperature to 210°C, and make the acid value below 20mgKOH / g. Cool down to 180°C, add 152g of phthalic anhydride, continue esterification at 225°C until the acid value is below 20mgKOH / g, then cool down and discharge, as acrylic modified alkyd resin for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com