Semiconductor device and manufacturing method thereof

一种半导体、器件的技术,应用在半导体器件领域,能够解决不可能迅速且精确滤色器设计、数据量大、临界尺寸不均匀等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

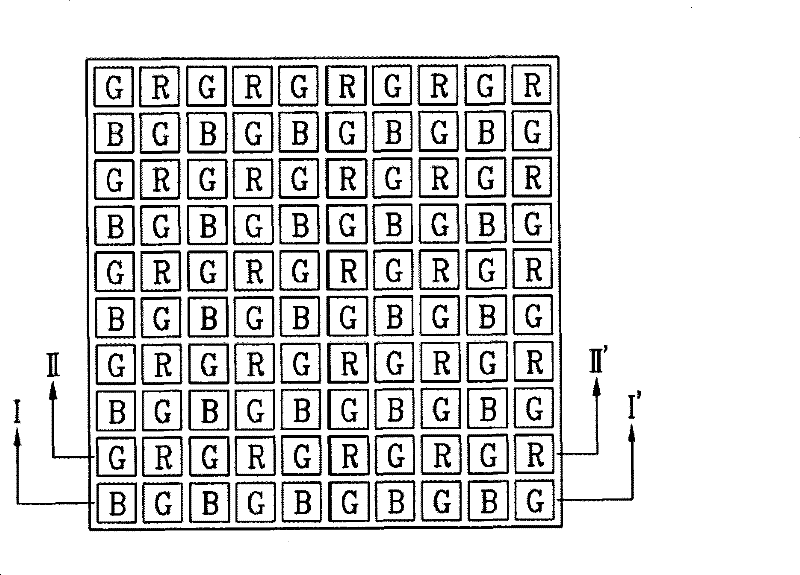

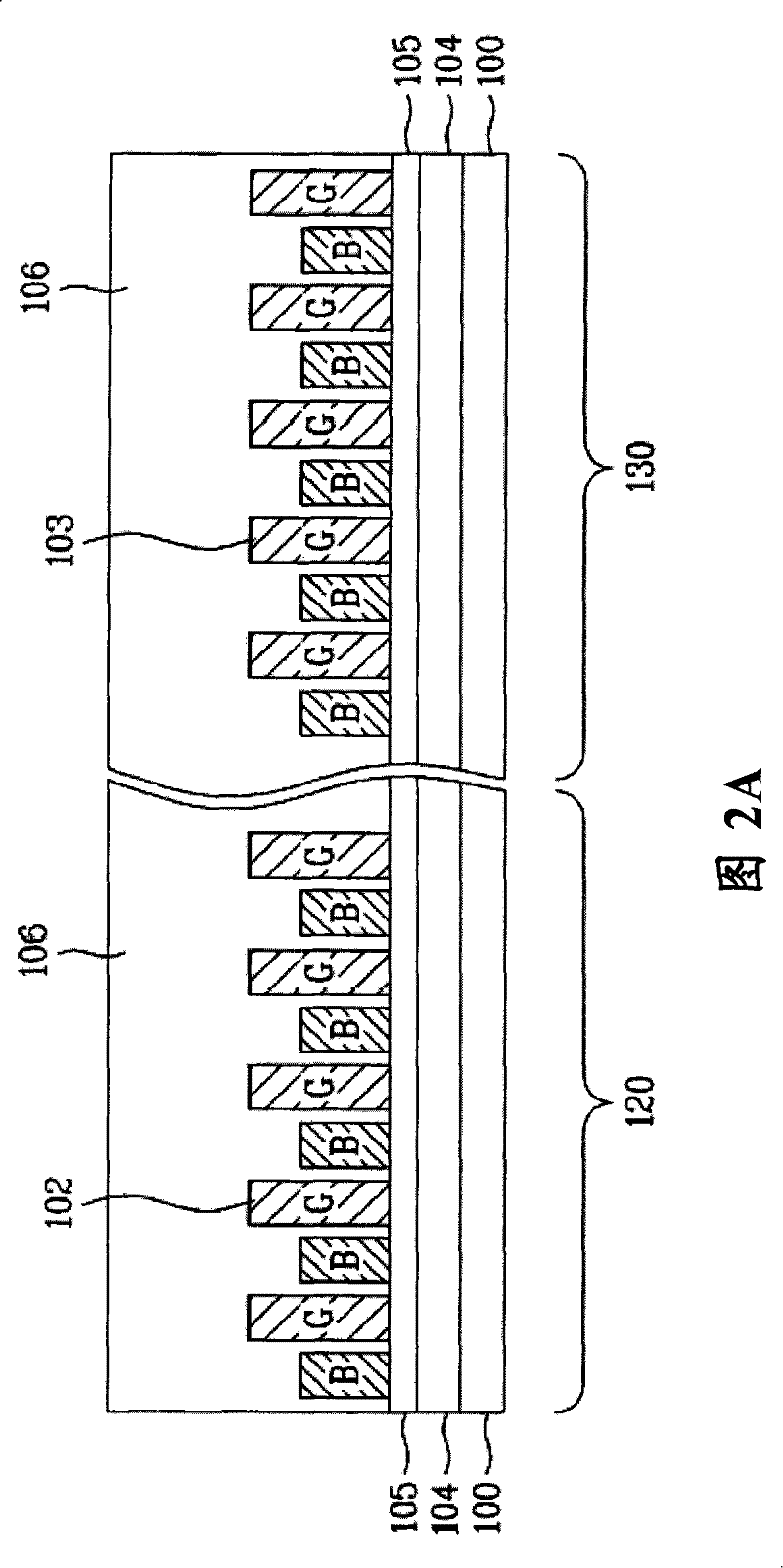

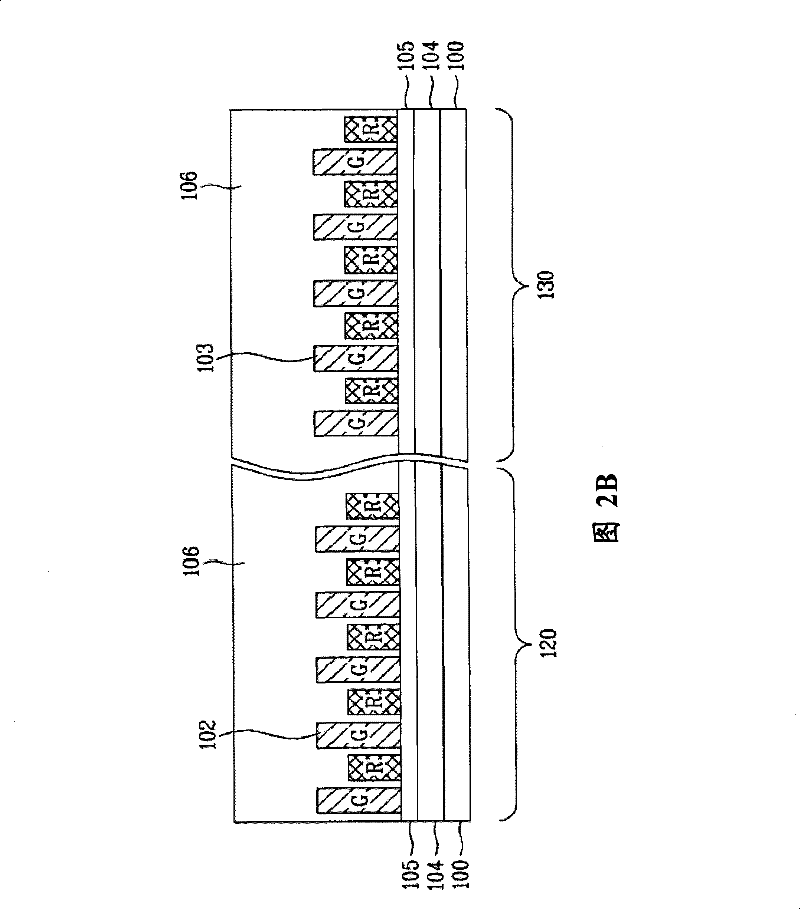

[0019] figure 1 is a plan view of a semiconductor device according to an exemplary embodiment of the present invention. Figure 2A and Figure 2B are cross-sectional views of semiconductor devices according to exemplary embodiments of the present invention along section lines II-I′ and II-II′, respectively.

[0020] like Figure 2A and Figure 2B As shown, the semiconductor device includes a dummy pattern area 120 and a main pattern area 130 for forming color filters. exist Figure 2A in, through the figure 1 The cross-sectional view of the semiconductor device taken along the line II′ in FIG. 1 shows the dummy pattern region 120 . exist Figure 2B in, through the figure 1 The cross-sectional view of the semiconductor device taken along the line II-II′ in FIG. 2 shows the dummy pattern region 120 .

[0021] refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com