Conductivity composite material and capacitor

A composite material, conductive polymer technology, applied in conductive materials, conductive materials, solid electrolytic capacitors, etc., can solve the problems of high ESR, low capacitance and high temperature stability of capacitors, and achieve enhanced adhesion and excellent stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

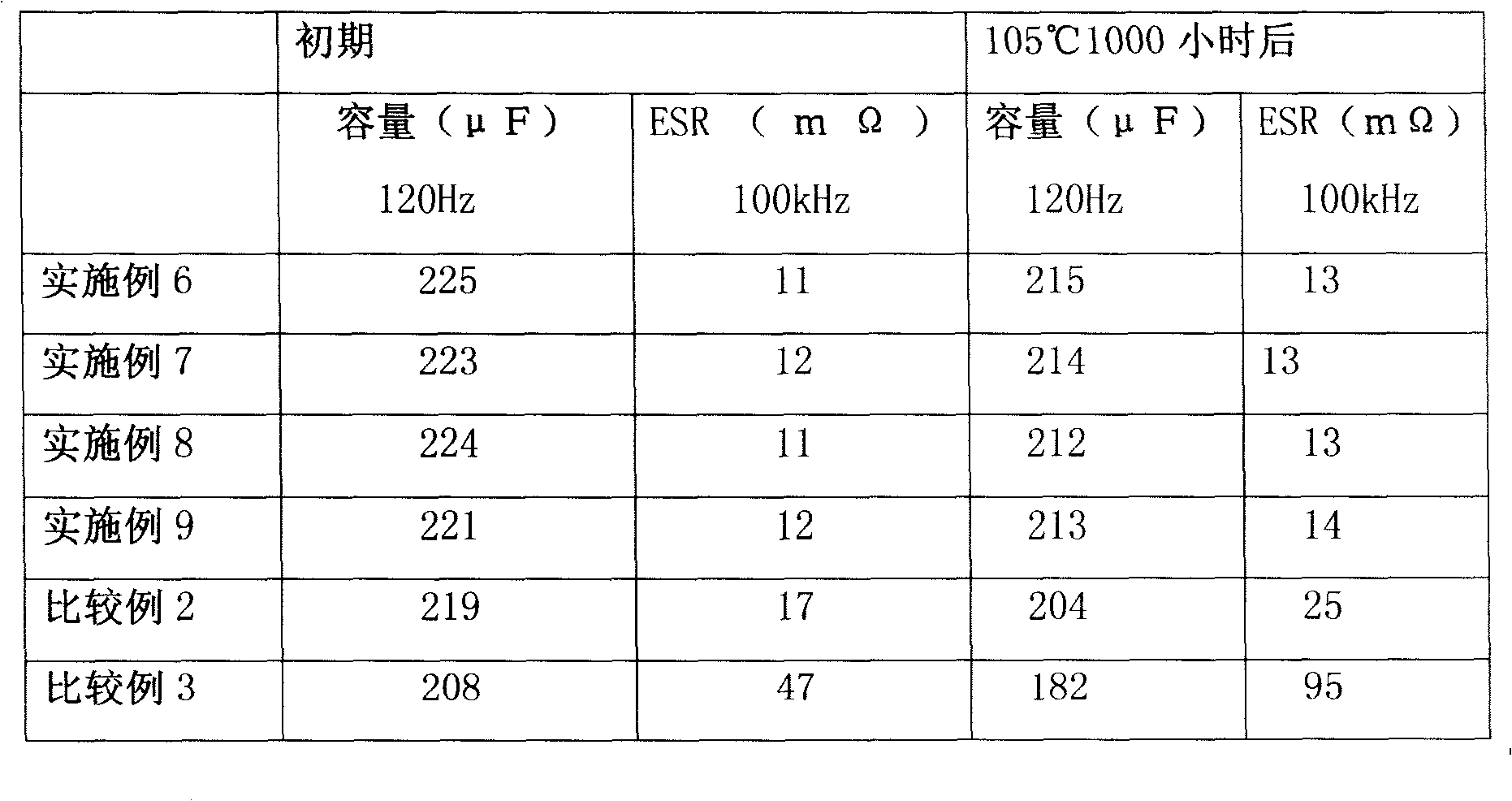

Examples

Embodiment 1

[0097] With 50g of polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene aqueous solution, 0.15g of SiO 2 Powder (aerosil, manufactured by Degussa), 50g of ethanol and 3g of ethylene glycol were mixed and stirred to obtain SiO 2Powder and mixed aqueous solution of polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene. After coating the mixed aqueous solution on the polyester film and drying it in an oven at 120°C for 60 minutes, the conductive thin coating film was obtained. Table 1 shows the results of evaluating the resistivity of the conductive thin coating film.

Embodiment 2

[0099] The same method as in Example 1, except that the SiO of 0.15g 2 Except for changing the powder (aerosil, manufactured by Degussa) to 0.3 g, a conductive thin coating film was produced in the same manner as in Example 1, and the resistivity of the conductive thin coating film was evaluated. The results are shown in Table 1.

Embodiment 3

[0101] The same method as in Example 1, except that the SiO of 0.15g 2 Powder (aerosil, manufactured by degussa) was changed to 0.15g of TiO 2 Except powder, all obtain TiO the same as embodiment 1 2 Powder and mixed aqueous solution of polystyrenesulfonic acid-poly(3,4-ethylenedioxy)thiophene. In the same manner as in Example 1, a conductive thin coating film was produced, and the resistivity of the conductive thin coating film was evaluated. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com