Carrier for exhaust-gas purification

A waste gas purification and carrier technology, which is applied in the direction of exhaust devices, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of increased driving days of exhaust gas heating systems, waste of fuel, and increased fuel costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

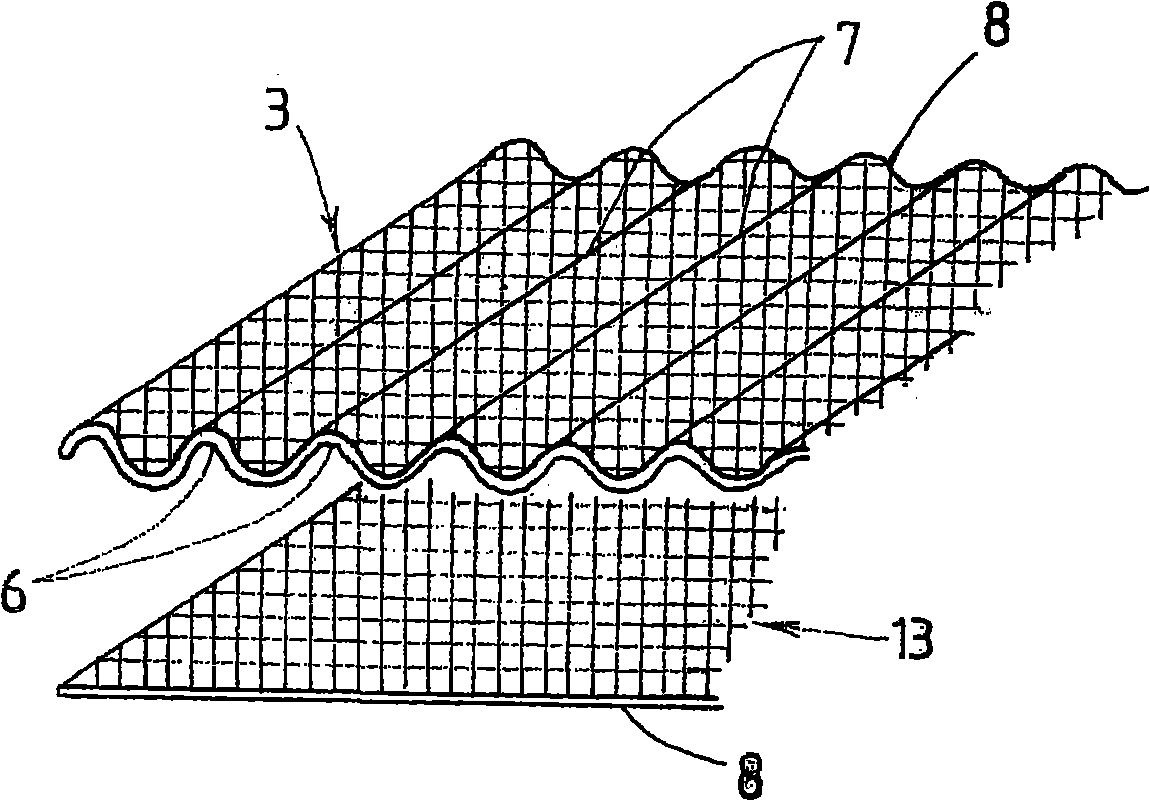

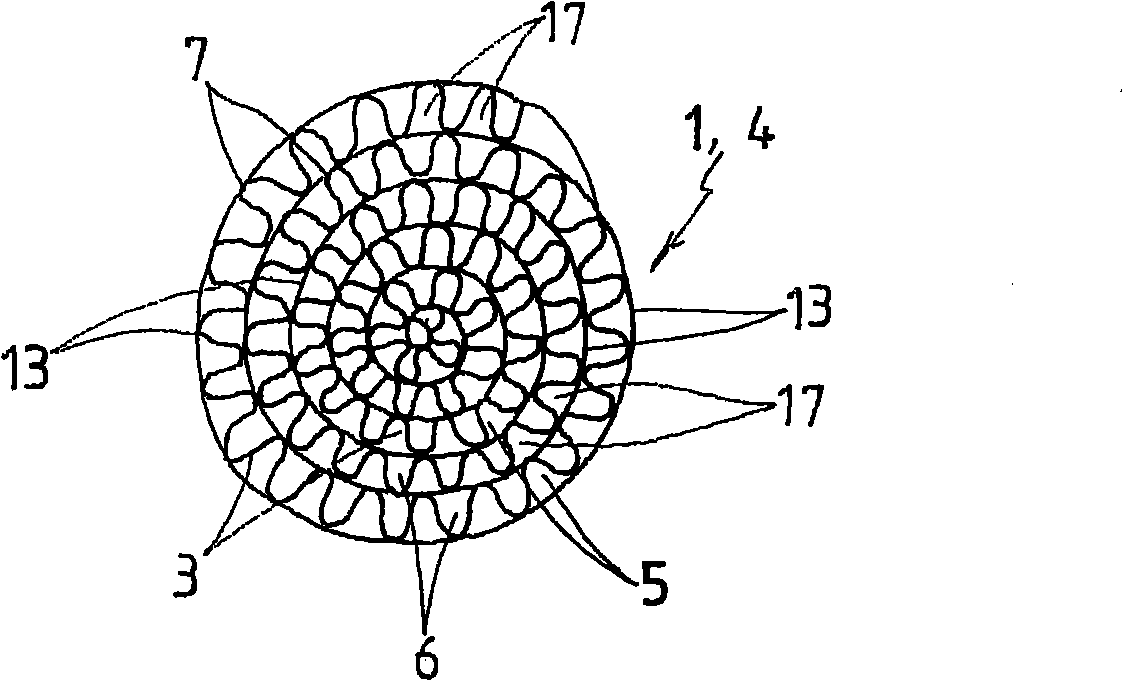

[0064] The exhaust gas purification device with built-in carrier structure for exhaust gas purification of the present invention is suitable for the following situation, that is, the exhaust gas from the engine, the burner and the gas generation source passes through the filter arranged on the exhaust passage, and under the action of the catalyst Particulate matter (PM), soot (soot), HC, NO contained in exhaust gas X and other harmful substances are burned, or redox reactions are carried out to transform and remove them, thereby purifying the exhaust gas. For example, it is more suitable for use in filters arranged on exhaust pipes, wherein the exhaust pipe discharges exhaust gases from new or old car engines, especially diesel engines.

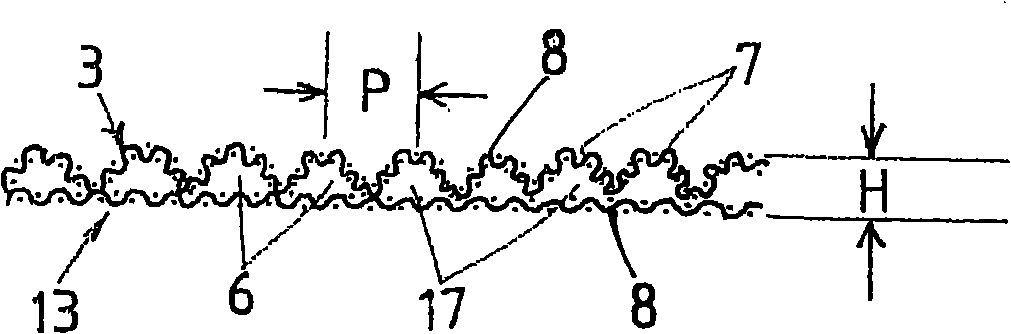

[0065] Next, an exhaust gas purifying device incorporating the exhaust gas purifying carrier structure of the present invention will be described with reference to the drawings.

[0066] This exhaust gas purification device has a built-in fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com