Temperature compensation type oscillator capable of remaining constant temperature

A technology for temperature compensation and constant temperature maintenance, applied in power oscillators, electrical components, etc., can solve problems such as large volume, dissipation, and general products without suitable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the following describes the specific implementation, The structure, characteristics and efficacy are described in detail as follows.

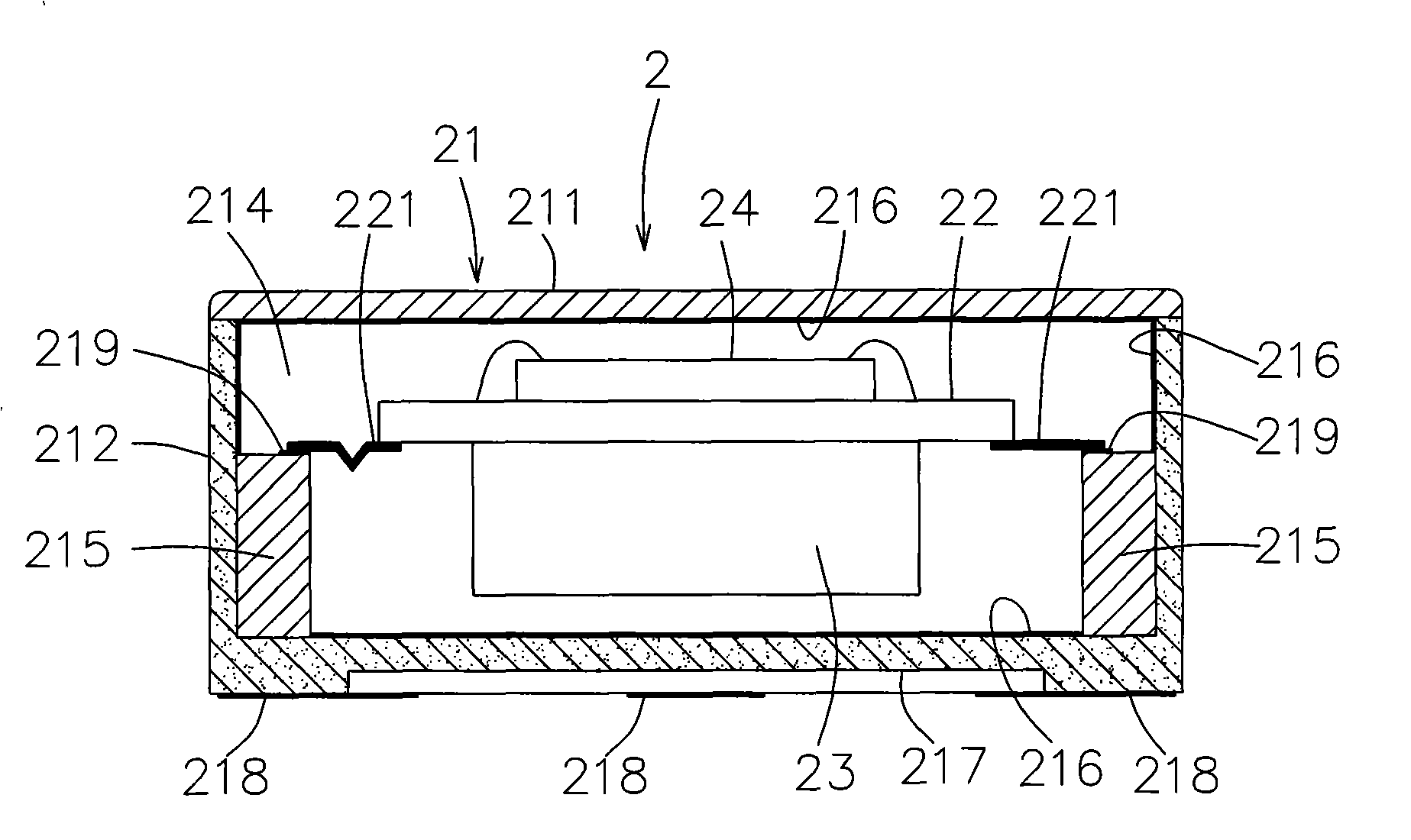

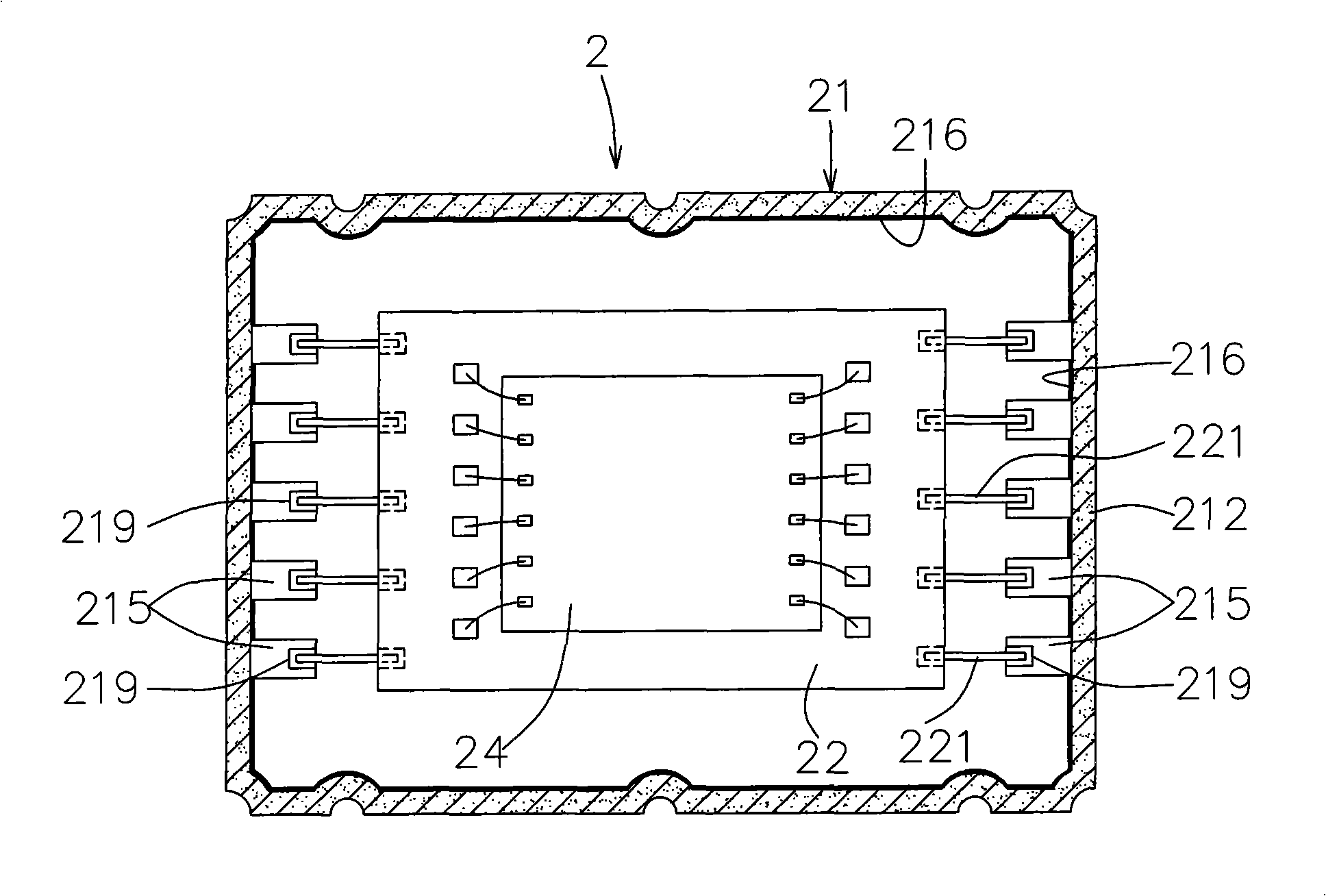

[0030] see figure 2 , image 3 and Figure 4 As shown, it is a preferred embodiment of the temperature-compensated oscillator device 2 that can maintain a constant temperature of the present invention. The temperature-compensated oscillator device 2 is an OCXO oscillator, which includes a casing 21, a circuit board 22, a A temperature-compensated oscillator 23 is arranged on the circuit board 22 and is suspended, and a heating control circuit 24 is arranged on the circuit board 22 .

[0031] The above-mentioned heating control circuit 24 is a miniaturized heating IC (integrated circuit) made by a semiconductor process, or called a monolithic IC (monolithic IC), hereinafter referred to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com