Process for manufacturing low-aliquation large-scale hollow steel ingot

A manufacturing method and hollow steel technology, which are used in the manufacture of tools, equipment for feeding molten metal into casting molds, casting molds, etc., can solve the problems of difficult core removal and inner core deformation, and reduce secondary oxidation inclusions. , The effect of reducing shrinkage and ensuring operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

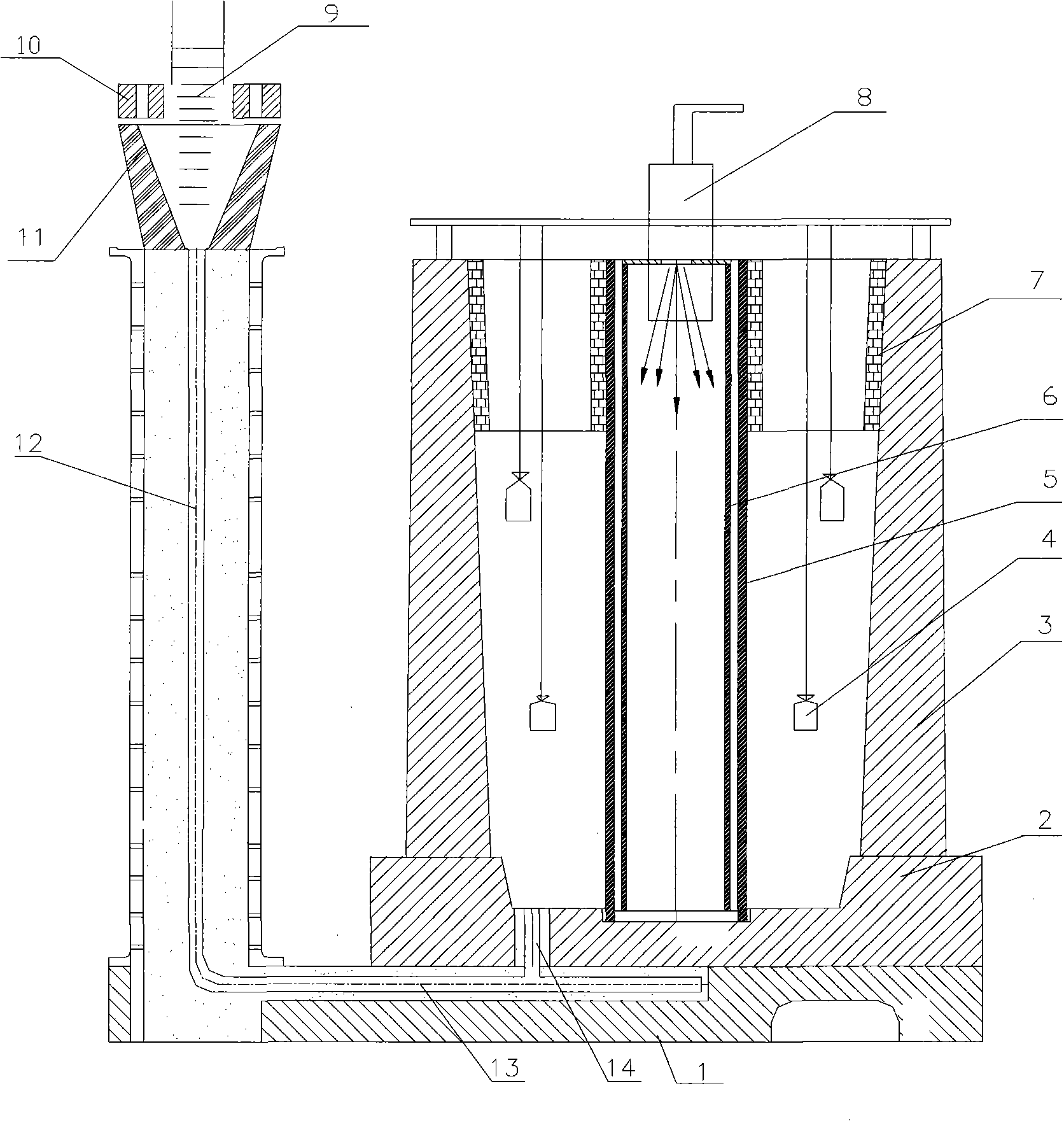

[0045] like figure 1 As shown, the weight of poured molten metal is 40 tons, the pouring speed is 5 tons / minute, and the material is No. 25 steel.

[0046] The implementation of the present invention is as follows: the process design is carried out by adopting the gas protection technology of the metal liquid surface, the design technology of the smooth filling and pouring system, and the advanced computer simulation technology, and mainly adopts the large air volume cooling technology and the steel structure nested core hole forming technology , Metal liquid early covering technology, gas protection flow injection technology, etc.

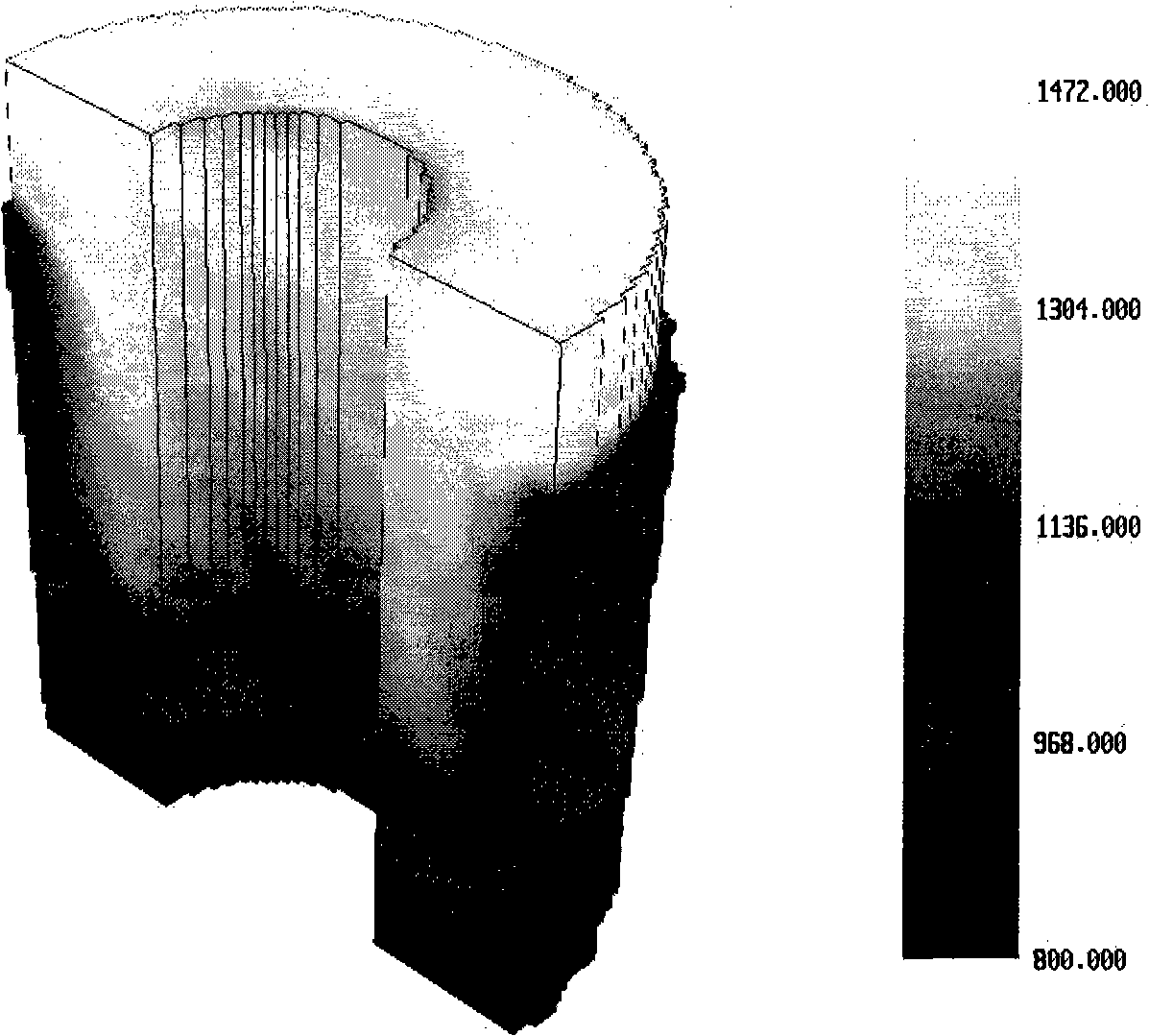

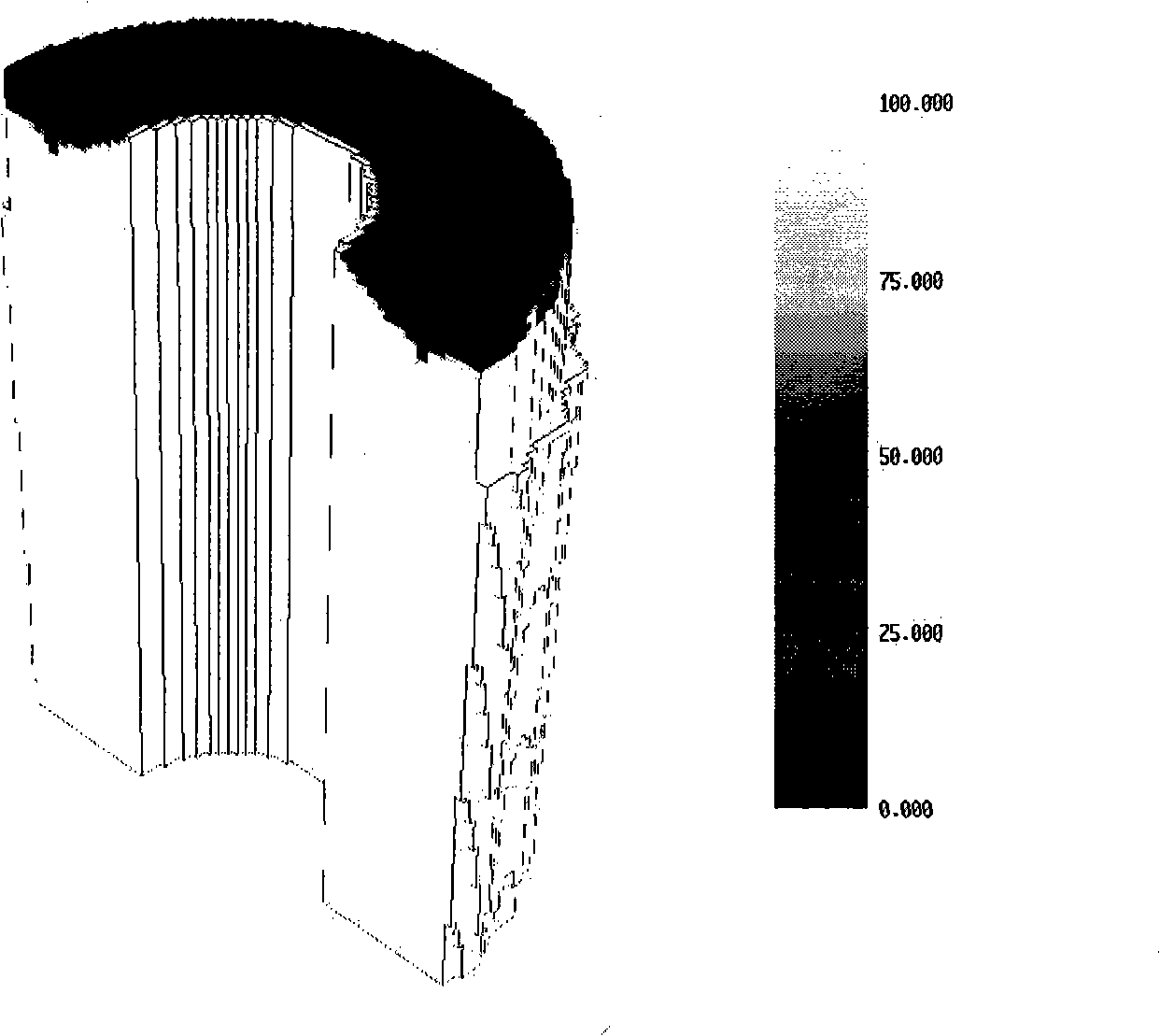

[0047] The advanced computer simulation technology ensures the rationality of the process design. The steel structure nested core hole forming technology and the large air volume cooling technology are used to complete the sequential solidification of the steel ingot and control the segregation position.

[0048] In this embodiment, the outer ste...

Embodiment 2

[0056] like figure 1 As shown, the weight of poured molten metal is 43 tons, the pouring speed is 7 tons per minute, and the material is No. 25 steel.

[0057] The implementation of the present invention is as follows: the process design is still carried out by adopting the metal liquid surface gas protection technology, the design technology of the smooth filling and pouring system, and the advanced computer simulation technology, mainly adopting the large air volume cooling technology, the steel structure nested core forming Hole technology, metal liquid early covering technology, gas protection injection technology, etc.

[0058] In this embodiment, the outer steel plate is 25 mm thick, the inner steel plate is 25 mm thick, the gap between the two steel plates is 60 mm, and the steel plates are supported by steel pipes. 50mm.

[0059] In this embodiment, the pressure of compressed air is 0.8MPa, and the gas flow rate is 400m 3 / min, the ventilation time is 5h.

[0060]...

Embodiment 3

[0062] like figure 1 As shown, the weight of poured molten metal is 45 tons, the pouring speed is 6 tons per minute, and the material is No. 25 steel.

[0063] The implementation of the present invention is as follows: the process design is still carried out by using the metal liquid surface gas protection technology, the smooth filling and pouring system design technology, and the advanced computer simulation technology, and mainly adopts the steel structure nested core hole forming technology, large temperature difference cooling Technology, narrow gap molding sand technology, pouring dispersed gate drainage technology, thick and large chassis forced cooling technology, etc.

[0064] In this embodiment, the outer steel plate is 20 mm thick, the inner steel plate is 10 mm thick, the gap between the two steel plates is 30 mm, and the steel plates are supported by steel pipes. 30mm.

[0065] In this embodiment, the pressure of compressed air is 0.5MPa, and the gas flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com