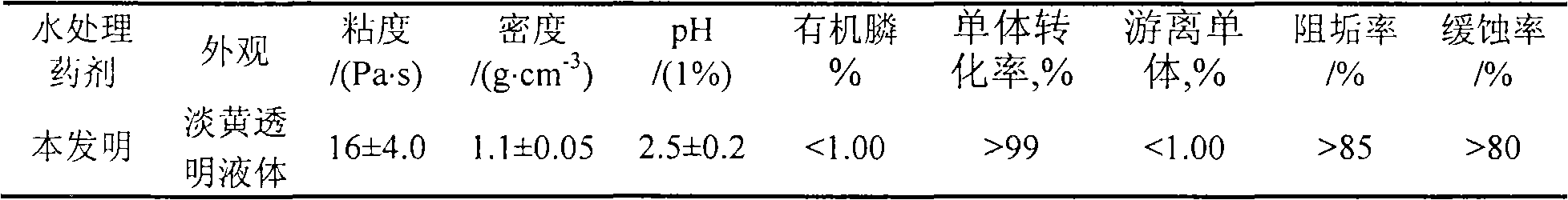

Four-element polymerization type corrosion inhibition antisludging agent and method for preparing same

A corrosion and scale inhibitor, polymeric technology, applied in the field of quaternary polymeric corrosion and scale inhibitors and its preparation, can solve the problems of corrosion and scaling in cooling water systems, achieve corrosion inhibition, molecular structure stability, drug use less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Take 80kg of water and put it in the reaction kettle, slowly add 25kg of maleic anhydride, stir, heat up to 85±5°C, add 5kg of molecular weight regulator isopropanol under stirring conditions; then prepare 10kg of hydroxypropyl acrylate and 20kg of The mixed solution (I) of acrylic acid 60~90kg; And the mixed solution (II) 60~90kg of 15kg sodium allyl sulfonate, 6kg sodium persulfate and 7kg sodium hypophosphite;

[0017] Note: Dissolve sodium allyl sulfonate and sodium persulfate before adding sodium hypophosphite. Water cannot be added all at once, but should be added slowly. Under the condition of continuous stirring, the temperature control of the reactor was adjusted to 85±5°C, and the mixed solutions (I) and (II) were added dropwise at the same time, and the dropping speed of the mixed solutions (I) and (II) was controlled to be within 1 hour at the same time After the dropwise addition, keep the temperature constant for 3 hours and cool to obtain the quaternary p...

Embodiment 2

[0019] Take 60kg of water and put it in the reaction kettle, slowly add 30kg of maleic anhydride, stir, heat up to 85±5°C, add 7kg of molecular weight regulator isopropanol under stirring conditions; then prepare 5kg of hydroxypropyl acrylate and 10kg The mixed solution (I) of acrylic acid is about 60~90kg; And the mixed solution (II) 60~90kg of 7kg sodium allyl sulfonate, 4kg sodium persulfate and 5kg sodium hypophosphite; According to the method and step of above-mentioned embodiment 1 to operate.

Embodiment 3

[0021] Take 70kg of water and put it in the reaction kettle, slowly add 40kg of maleic anhydride, stir, heat up to 85±5°C, add 8kg of molecular weight regulator isopropanol under stirring conditions; then prepare 6kg of hydroxypropyl acrylate and 15kg of About 60kg of the mixed solution (I) of acrylic acid; And about 60kg of the mixed solution (II) of 9kg sodium allyl sulfonate, 6kg sodium persulfate and 6kg sodium hypophosphite; Operate according to the method and step of above-mentioned embodiment 1.

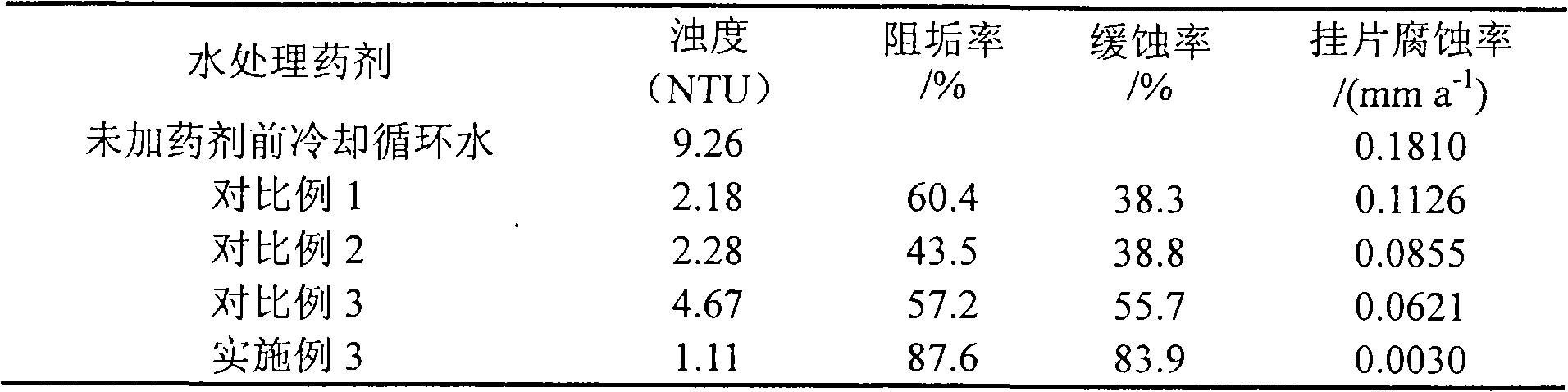

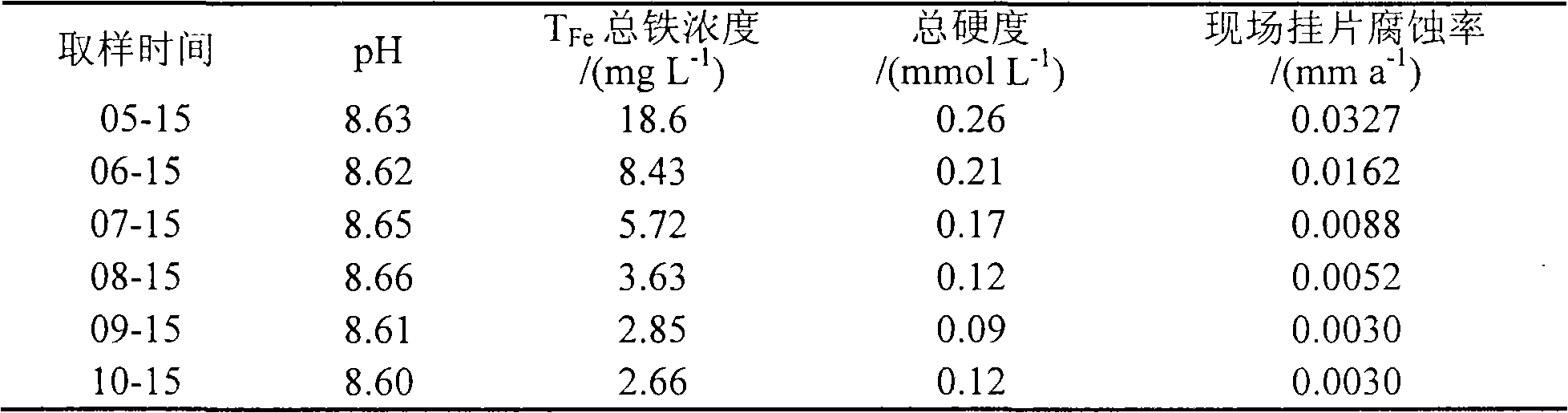

[0022] Specific comparison method

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com