Novel plate-type impeller feeder

An impeller feeder, plate type technology, applied in the direction of rotary conveyor, conveyor, conveyor objects, etc., can solve the problems of affecting material transportation, low efficiency, residue, etc., and achieve good comprehensive effect and high removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

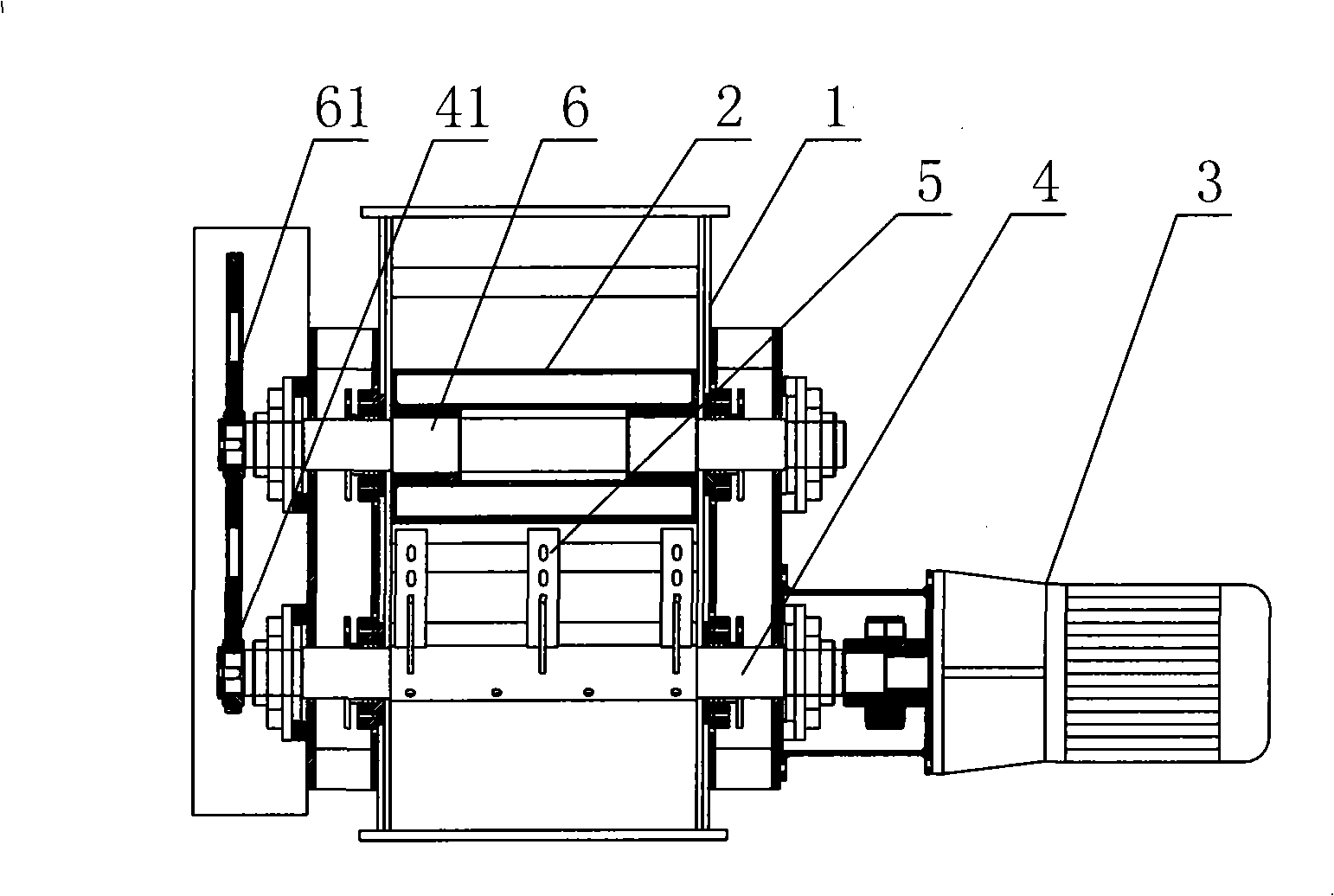

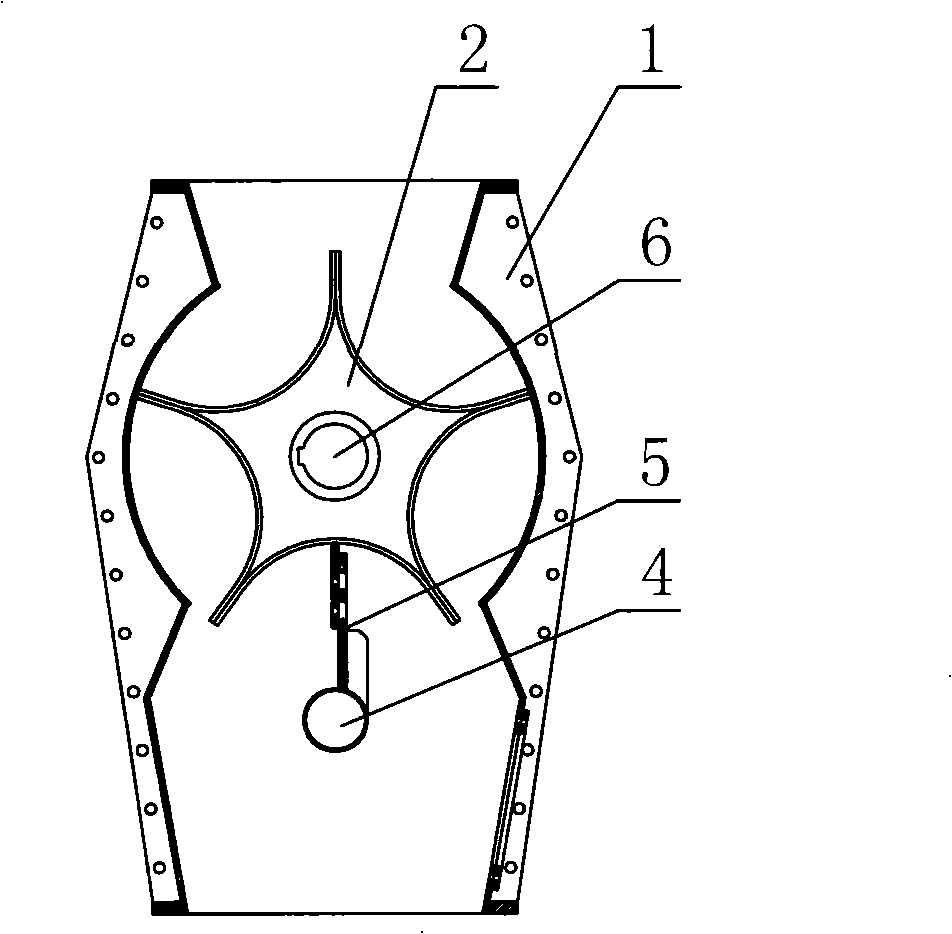

[0012] As shown in Figure 1 and Figure 2, it is an embodiment of the novel plate impeller feeder of the present invention, comprising a housing 1, an arc-shaped plate impeller 2 and a motor 3 installed on the housing, and placed side by side on the housing 1 A sweeper rotating shaft 4 is also installed on the lower side of the plate impeller 2, and a sweeper 5 is installed on the sweeper rotating shaft 4. In this embodiment, the sweeper rotating shaft 4 is linked with the rotating shaft 6 of the plate impeller. The sweeper rotating shaft 4 is interlocked with the motor 3 , the end of the sweeper rotating shaft is provided with a driving gear 41 , and the end of the rotating shaft 6 of the plate impeller is provided with a driven gear 61 interlocking with the driving gear 41 . Drive gear and driven gear periphery are provided with shield 7.

[0013] In practice, the plate impeller of the present invention often adopts a straight plate structure, and the heels of two adjacent st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com