Aluminum member or aluminum alloy member with excellent corrosion resistance

A technology of aluminum alloy components and components, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, anodic oxidation, etc., can solve the problems of insufficient improvement effects, etc., and achieve excellent adhesion, excellent gas corrosion resistance, and plasma resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

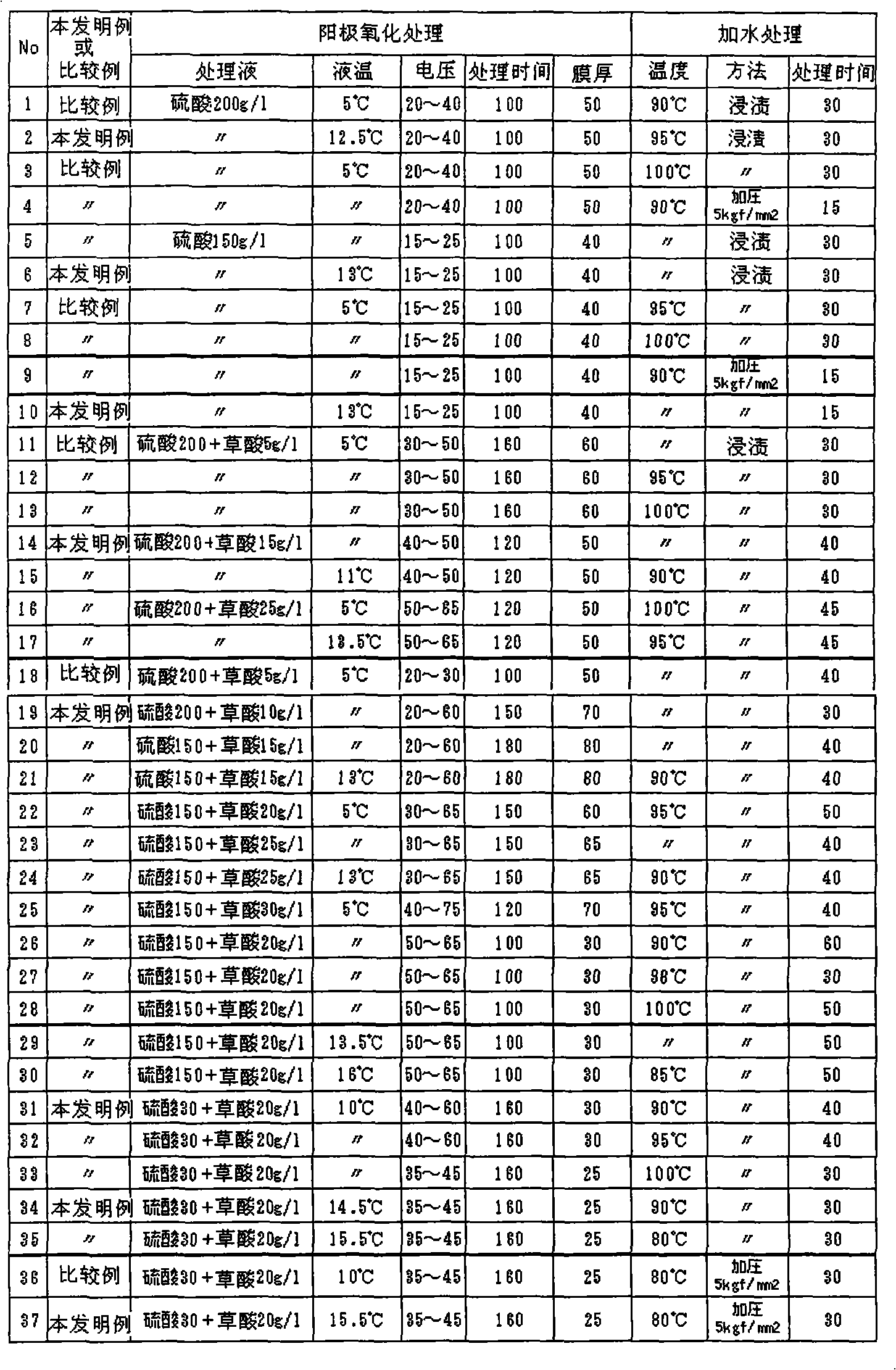

[0049] Taking JIS 6061Al alloy sheet or 5052Al alloy sheet (50~100mm×50~100mm) as the object, the final electrolysis voltage: 30~100V, treatment time: 20~200 minutes to anodize it, and then implement water treatment ( sealing treatment) to form various anodic oxide films (film thickness: 25 to 80 μm) on the surface of the Al alloy plate. The impedance of these membranes was measured (10 -2 the value of Z at Hz). from 10 -3 Hz to 10 5 Hz to measure its impedance, selected at 10 -2 The value at the Hz time is used as an index of the stability of the film. In addition, the hardness of the same film was measured with a micro Vickers hardness tester.

[0050] Next, as a test for confirming plasma resistance, plasma gas (gas: BCl 3 / 50%+Cl 2 / 50%sccm, ICP: 800-1000W, bias voltage: 30-120W, gas pressure: 2mT, temperature: 30-80°C), etch the film, and investigate the etching rate at this time. In addition, as a test of corrosion resistance, these aluminum alloy plates were imm...

Embodiment 2

[0058] Taking JIS 6061Al alloy sheet or 5052Al alloy sheet (50~100mm×50~100mm) as the object, the final electrolysis voltage: 30~60V, treatment time: 60~200 minutes for anodic oxidation treatment, and then implement water treatment ( sealing treatment) to form various anodic oxide films (film thickness: 10 to 60 μm) on the surface of the Al alloy plate. The impedance of these membranes was measured (10 -2 the value of Z at Hz). from 10 -3 Hz to 10 5 Hz to measure its impedance, selected at 10 -2 The value at the Hz time is used as an index of the stability of the film. In addition, the hardness of the same film was measured with a micro Vickers hardness tester.

[0059] In addition, the aluminum alloy plate was immersed in HCl (7% aqueous solution), and measured until H 2 Foaming time. Then use the DC power supply to measure the insulation breakdown voltage.

[0060] Table 3 shows the details of the formation and treatment conditions of each anode coating, and Table 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com