Hydrophilic active biological film suspend carrier and method for making the same

An active biofilm, suspended carrier technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. problems, to achieve the effect of improving wettability and mass transfer, promoting the speed of biochemical reactions, and increasing the speed of biochemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] carrier structure

[0036] The hydrophilic active biofilm suspension carrier adopts a plum-shaped tubular structure or a circular tubular structure, with a wall thickness of ≤0.5mm and a density of ≥0.965g / cm 3 , ≤0.985g / cm 3 .

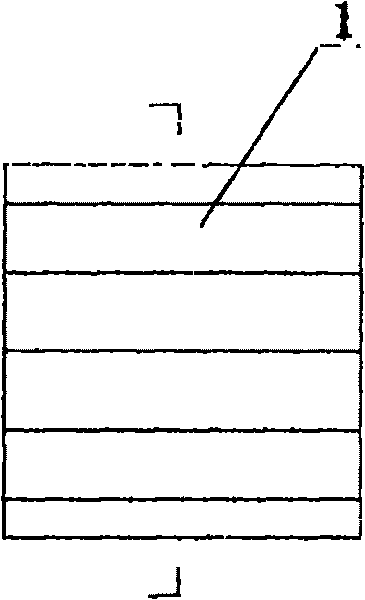

[0037] exist figure 1 The middle casing (1) is a quincunx tubular structure.

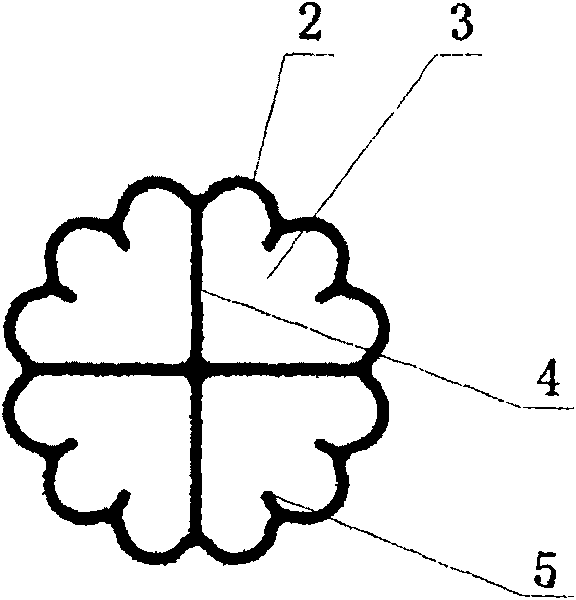

[0038] exist figure 2 The housing (1) is composed of plum blossom petals (2) connected end to end, and a cross-shaped reinforcing rib (4) is arranged in the housing (1), which divides the housing (1) into four inner cavities (3). Protruding teeth (5) are arranged on the connecting points of the plum blossom petals (2) of (3).

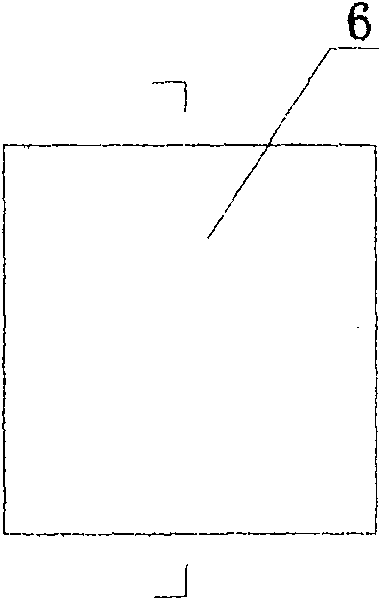

[0039] exist image 3 The middle casing (6) is a circular tube-shaped structure.

[0040] exist Figure 4 A cross-shaped reinforcing rib (9) is arranged in the middle casing (6), and the casing (6) is divided into four inner cavities (8), and protruding teeth (7) are arranged on the inner wall of the casing (6).

[0041] Raw materials ...

Embodiment 2

[0074] carrier structure

[0075] The hydrophilic active biofilm suspension carrier adopts a plum-shaped tubular structure or a circular tubular structure, with a wall thickness of ≤0.5mm and a density of ≥0.965g / cm 3 , ≤0.985g / cm 3 .

[0076] exist figure 1 The middle casing (1) is a quincunx tubular structure.

[0077] exist figure 2 The housing (1) is composed of plum blossom petals (2) connected end to end, and a cross-shaped reinforcing rib (4) is arranged in the housing (1), which divides the housing (1) into four inner cavities (3). Protruding teeth (5) are arranged on the connecting points of the plum blossom petals (2) of (3).

[0078] exist image 3 The middle casing (6) is a circular tube-shaped structure.

[0079] exist Figure 4 A cross-shaped reinforcing rib (9) is arranged in the middle casing (6), and the casing (6) is divided into four inner cavities (8), and protruding teeth (7) are arranged on the inner wall of the casing (6).

[0080] Raw material...

Embodiment 3

[0113] carrier structure

[0114] The hydrophilic active biofilm suspension carrier adopts a plum-shaped tubular structure or a circular tubular structure, with a wall thickness of ≤0.5mm and a density of ≥0.965g / cm 3 , ≤0.985g / cm 3 .

[0115] exist figure 1 The middle casing (1) is a quincunx tubular structure.

[0116] exist figure 2 The housing (1) is composed of plum blossom petals (2) connected end to end, and a cross-shaped reinforcing rib (4) is arranged in the housing (1), which divides the housing (1) into four inner cavities (3). Protruding teeth (5) are arranged on the connecting points of the plum blossom petals (2) of (3).

[0117] exist image 3 The middle casing (6) is a circular tube-shaped structure.

[0118] exist Figure 4 A cross-shaped reinforcing rib (9) is arranged in the middle casing (6), and the casing (6) is divided into four inner cavities (8), and protruding teeth (7) are arranged on the inner wall of the casing (6).

[0119] Raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com